A very simple device for making an incandescent spiral from nichrome wire, it can be done in just five minutes. With the help of such a device, back in Soviet times, thousands of spirals for heating "goats" and boilers were made at our factory. Although the nichrome wire due to nickel in the composition is very expensive, no one has yet canceled the freebie and therefore the fixture can be useful to someone.

Video work ways

The appearance of the resulting spiral.

Point 1. Prepare.

What we need for this:

• Wooden block, approximately 100x5x5 cm.

• Wooden rail, approximately 100x4x4 cm.

• Small nails 20-30 mm. 4-5 pcs.

• Self-tapping screws 3 pcs.

• A round bar 120 cm long, its diameter depending on the required winding diameter of the spiral (D = 4-10 mm.)

• Drill and drill D = 4-5 mm.

• Two clamps.

• Hacksaw for metal or grinder with a thin disc.

• Screwdriver, hammer.

Item 2. Production fixtures.

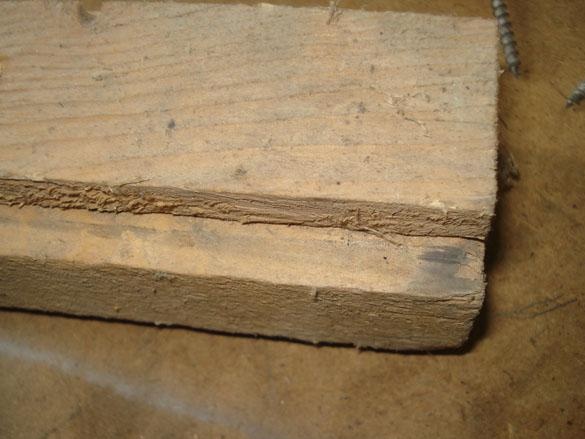

From above, on a large bar, we impose a thin rail, we shift it to one of the sides to get an internal angle, about 1x1 cm in size, a bar will be laid there.

If the bar is of a larger diameter, then the dimensions of the corner should be increased to 1.5x1.5 cm.

We twist the rails with two screws, at the beginning and in the middle of the bar. On the other hand, in a thin rail, we drill a hole D = 4 mm. So that the self-tapping screw easily passes, rather than twisting along the thread.

We take the rod necessary in diameter, most often D = 5 mm is used., Bend one end of it in the form of a handle for rotation.

On the other hand, we make the bar washed down with a hacksaw for metal or a grinder, 4-5 mm.

We lay the finished bar in the corner groove of the wooden base and five centimeters from the edge and the handle, pressing, we hammer the nail, we do not finish it to the end of 1 cm.

In principle, the device is ready, it remains to fix it with clamps to the corner of the table or workbench so that nothing prevents the rotation of the handle.

Item 3. Operation of the device.

Take a nichrome wire of the calculated length and cross section.

To wind the spiral, it is necessary to insert the edge of the wire into the cut of the rod, if it is slightly thicker washed down, then we flatten the tip of the nichrome with a hammer and then insert it.

Now we lay the bar at the beginning of the bar-base so that the wire touches a nail driven in advance when winding.

The incoming wire itself is passed under the rail in the same place, now we need to tighten the last self-tapping screw, thereby creating the necessary tension and preliminary straightening of the feeding wire.

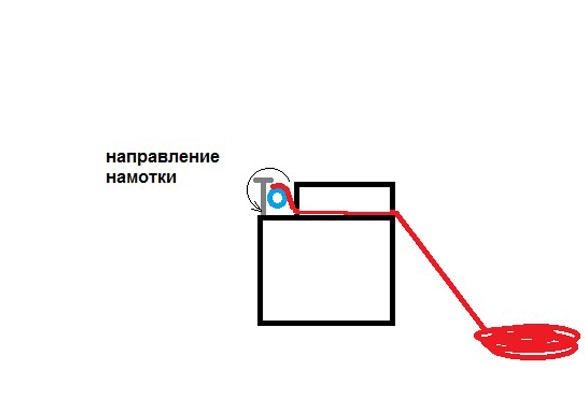

We start winding, the direction of rotation should be such that the wire goes to the top of the bar, and not below the bottom, then the bar itself will be pressed to the bar without trying to "run away".

Winding direction.

Thus, we make the winding of the entire length of the spiral.

And if you immediately wind from a large bay of wire without first biting off the desired length of a piece, then you can periodically remove the finished spiral from the bar and measure the resulting resistance with a tester and, if necessary, continue winding again.

Such a device can curl not only incandescent spirals, but any wire, for various purposes, for example, a spiral radio antenna, etc.