Steam turbine. The first mention of steam engines dates back to the beginning of the first century BC. The relatively simple principle of operation has made this steam engine the main for mankind for hundreds of years. Let's try to make the simplest model steam turbine do it yourself.

We will need:

-Tin. I took a little from tomato paste.

- Tin lids from cans of larger diameter.

-Tight strip. It can be cut from the side of the can.

-Rivets with a diameter of 3mm and a length of 7 and 14mm.

- Screw with nut M5.

-Aluminium wire.

-Candle. In place of a candle, it is better to use a dry fuel tablet or spirit lamp.

From the lids we cut two circles. One is customized to the size of the can, which will be a steam boiler. The second will be a turbine. We choose its size at our discretion, depending on the size of the entire structure. A long rivet, which will be a nozzle on one side with a hammer, and reduce the diameter to 0.6-0.7mm.

We make two holes in the cap: under the nozzle and under the filler hole. We place the filling hole a little on the side so that the turbine does not interfere with turning the screw.

Solder the nut and nozzle from the rivet to the lid. These rivets are made of aluminum, so you will have to use either universal soldering liquid or a special flux for brazing aluminum. I used F59A.

Solder the lid to the jar. It should be noted that almost all modern cans are made with an additional polymer coating; therefore, all details must be cleaned with sandpaper before soldering.

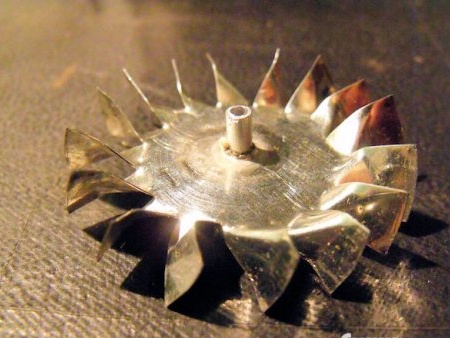

We make a turbine. To do this, divide the tin circle first into 4 parts, then each quarter into 2 parts, and finally each slice in half. Cut slices to about the middle of the radius. We bend the turbine blades with pliers. Solder the rivet head to the center.

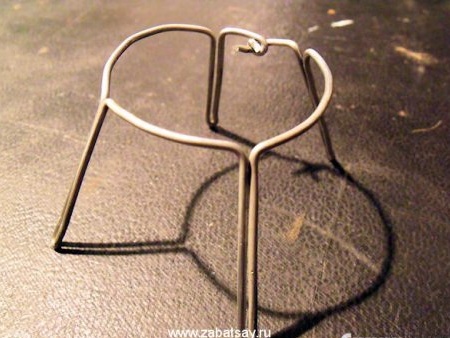

We bend the turbine holder from the tin strip in the form of the letter P. The width is selected slightly more than the length of two rivets.

Solder the turbine into the holder so that it rotates freely. As the axis, we take the cut off central core of the rivet.

Solder the holder with the turbine to the cap over the nozzle. Be sure to check that she does not cling to anything.

Stand Options can be any. The simplest thing is to bend out of aluminum wire.

The turbine is ready to run. Pouring water will be much easier using a plastic bottle from under the drops from a cold. Do not pour more than half the volume of our boiler. It is ideal to use a washer cut from the lead sheath of the cable as a sealing washer. You can use leather. If there is neither one nor the other, it is enough to take the standard and tin up.

Now it remains to start a fire and wait for the water to boil. Steam will escape under pressure from the nozzle and turn the turbine.

The view of the working turbine is mesmerizing. Now there was a desire to make a civilian desktop version. Something in the style of steam punk.