The most important thing in the house is comfort. And one of its main attributes is the sofa.

The corner sofa is very comfortable in its shape, as it can easily be placed in almost any room. You can store various things in it, use it instead of a closet or pantry. A sofa is a very necessary and useful thing in any home.

An important factor is that when making a sofa do it yourself, you can save a decent amount of money than buy it in a store.

When making a corner sofa for the first time, it would be better to make the most simplified option. You should choose not complex shapes, without semicircles and ovals.

So, you need to start making a sofa with outline drawings of its intended shape and size.

To make the frame you need:

- plywood

- wooden boards and bars

- wood chipboards (chipboard)

- fiberboard (fiberboard)

- and oriented particle boards (OSB)

For soft parts and upholstery, we will need:

- foam rubber

- synthetic winterizer

- and batting

In general, the material can be replaced with any other available options.

You need to start assembling from the lower frame of the sofa (meaning seating).

The frame needs to be twisted from the back with screws or corner metal plates. The width of the board should be approximately 20 to 25 cm.

With sheets of oriented strand boards (OSB), the bottom of the box is hemmed

Cover the upper part of the box, in several ways:

- Thoroughly tighten the OSB sheets or fill the binding of the rope belts, and then lay the foam pillow up.

- Glue the foam on the OSB and make a one-piece seat cover, which will need to be attached to the frame using loops. And then make it like a niche.

- Or the third option, in which you can use the two previous ones: one half must be hammered, and the second should be made lifting.

Next, we proceed to the manufacture of the back of the frame.

The backrest frame is made of boards. The back support part is sheathed with OSB sheet, and the back part can be upholstered with cotton cloth or spandbond

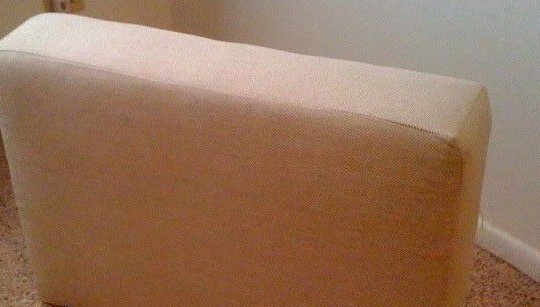

In the photo you can see what a closed seat looks like.

The dimensions of the back (width, length, height) directly depend on the finishing materials that are available. These include foam mats and back cushions. In general, you can make them yourself from foam rubber.

The other part of the sofa needs to be done in the same way step by step, to the upper seat. On the sheet of OSB, which is cut to the size of the box, it is necessary to attach foam rubber with aerosol glue, then cover with spandbond and synthetic winterizer, stretch it well and nail the edges from the back side around the entire perimeter with a stapler. Then sew the cover in size and completely tighten. After what has been done, it will fit well in the upper seat. If desired, the cover can be fixed with loops.

The corner element that will connect the sofa is also made from available materials. True, in its manufacture, it is necessary to be guided by the dimensions of the side parts of the sofa. The lower front part and back are glued with batting, and on top we lay out spandbond. Its surface is slippery, so it will be convenient to pull and level the fabric and upholstery

All three backs need to be beaten with a cotton cloth or any other that is available.

In the manufacture of the corner sofa, one of the most important steps is the sewing of covers and the upholstery of parts that will not be removed. To do this, you need a sewing machine. If you don’t have one, you can just cut out all the necessary details and ask someone you know to do sewing.

From wooden blocks with through holes, legs for frames are made. The legs are attached with screws to the lower frames, which were made by the size of the boxes from a wooden corner plinth. The frame must be attached to the frame and stretched with a long screw through the holes that are cut in the legs to the main frame.

After installing the corner part, we move the side parts to it, then we twist the lower parts of the walls together.

Now you need to make the side armrests. It is very simple.

We need to twist the lightweight frame to the size that we need and wrap it with sintepon or batting as desired. In extreme cases, you can paste over with foam.

[center]

Next, you need to sew the cover and tighten the frame with it.

You can attach the cover to the main frame in two ways: fasten it with self-tapping screws or with the help of clamping furniture knitting needles.

Good luck in this not easy, but very productive business!