Probably every guitarist has a limit to his volume. Have you encountered such a case when you are not heard? If you have your own acoustic guitar, then this problem is partially solved. But after all, every guitarist, deep down, wants to become a legend. Or a situation where the number of your listeners exceeds ten people. You play in a large hall or on the street. Do you want an electric guitar .... I think you can name a bunch of reasons.

But one reason unites these reasons - it is a pickup. A device that will convert the sound of your instrument into an electrical signal. After that, the sound can be amplified, processed with all sorts of effects, and many more. another ...

Today you can learn how to make a single-type pickup with your own hands. In fact, this sensor is an inductor that is wound around a permanent magnet. Steel strings that oscillate near it affect the field and create a weak alternating current. Which is a copy of the modulation frequency response of a sound wave.

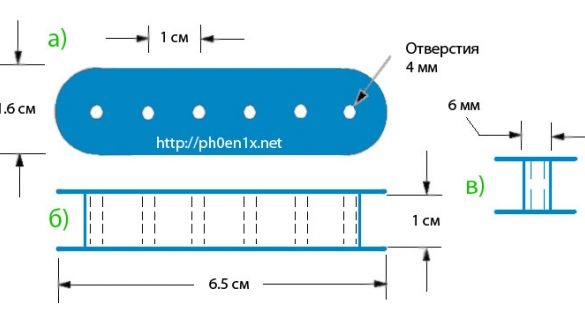

So, first we need to make a single frame. To do this, you can use the drawing.

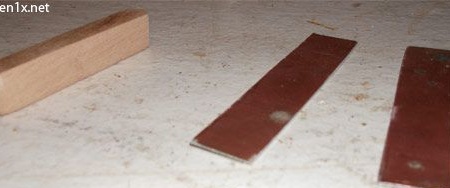

In the photos below, we can see the base of the frame. It is made of plexiglass.

And also, two plates of foil fiberglass. Then the foil can serve as an excellent screen when it is connected to the mass.

Further, for the cores of the coil, a guide was found from an old matrix printer.

Its diameter is 5 mm.

Now, you can drill 6 holes in the base, for cores. By the number of strings. In order not to damage the base, it was wrapped in cardboard for cushioning, and clamped in a vice.

After that, with the help of the base, textolite was piled and drilled.

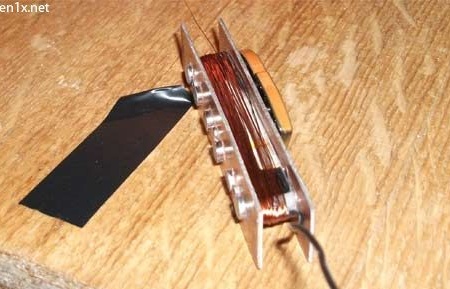

Here is the case assembled using miniature screws, of which there are many in Chinese toys.

Neodymium magnets from old hard drives were taken as magnets. They are good in that they are quite thin, but strong.

Further, after long and persistent "suffering", a coil was wound.

The ends are tinned and soldered to the wiring, insulated.

With the help of electrical tape, the coil itself is insulated.

The foil screen is fixed using a bare wire. Connected to a PCB foil and a wire that removes the mass.

Further, magnets are attached to the bottom so that each of the cores is in contact with the magnet.

That's all. As for me, it’s not very aesthetically pleasing, but it works!

Thanks to everyone.