Virtually any tree growing in Russia is suitable for a regular onion.

So, onions can be made from maple, juniper, ash, hazel, birch, oak and elm.

The workpiece must be cut in winter in the cold from 10 to 15 degrees.

The blank must be without thermal and mechanical damage, and not have excess growths.

The length of the onion blank should be 30 cm longer than the length of the onion, as cracks may appear, for this 15 cm is left on both sides.

No need to remove the bark from the sawn log.

It is necessary to cover the ends of the workpiece with oil paint. This is done so that the drying is uniform and there are no internal defects in the wood. If this is not done, then for a long service onions can not be fed up.

After processing, the workpiece must be dried at room temperature and in a vertical position. At the same time, the air in the apartment should not be very dry, because the tree can dry out and everything that has been done will be in vain. You need to dry from 2 to 5 months, depending on the conditions.

First treatment.

So, the existing workpiece is a log.

It is necessary to make a board from it as in the following figure.

You can do this using one of the options below:

- Handle with an ax

- Cut with a saw

- Split with wedges.

The board should be as thick as the future bow in the handle, approximately 3 cm.

After the board has the required thickness, markings should be made on it.

You also need to carefully inspect the board for defects and skew layers.

In the following figure, you can see how to correctly make a markup diagram.

You should pay attention to the fact that the bark has not yet been removed, so you need to be extremely careful and not damage the outer part of the onion.

All that is needed must first be separated with an ax, and then continue with a knife and a planer. After what is done, you will have on your hands a side profile of the bow.

Now you can proceed to the formation of the frontal profile.

The ratio between the width of the handle and the width of the end of the shoulder should be approximately 3/2. In the first stages of work you need to be very careful. From what accuracy and accuracy everything is done, the uniformity of the bow shoulders will depend. In the early stages, you can not bend the onion, as this can lead to splitting of the onion stock and spoil it.

Onion cross section directly depends on the available thickness of the workpiece. It can be lentil or almost rectangular.

Steaming (last stage)

At this stage, a bow bend will form.There are manufacturers who at this stage soak the workpiece in different solutions and infusions. But after processing the workpiece with steam, the tree also masters all the necessary properties.

So, why do you need to steam onions?

- When the wood dries up during drying (therefore, it is impossible to bend the onion before steaming)

- In the case when the primary procurement was not straight. This happens often, do not be afraid of it. For the frontal profile of the bow, it is not necessary that it be straight. This will not affect the shooting.

- If you need to make a short bow (for example, one of the Slavic options 1 - 1.3 m).

- In the manufacture of onions with reverse arch.

- When a “light” bow is made (for example, a game bow).

- In order to give it an aesthetic look.

At the very beginning of manufacturing, the workpiece looks like this:

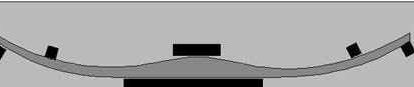

It is necessary to get such a bend:

To do this, you will need to steam off the shoulders of the onion (when they are steamed, they become very plastic and you can easily give them such a shape)

You need to steam the shoulder until it can be easily bent.

Only parts that are shown in white should be steamed.

It is necessary to steam it at the same time, so that the shoulders of the onion dry evenly and simultaneously.

After steaming the shoulders of the bow, you need to bewildered in a special, pre-prepared slipway.

The bars are depicted in black, between which the "hot" onion should be covered. The shape, quantity, and location of the bars depends on the desired shape of the onion.

You can do it another way and steam the onions in the center.

Then place boards under his shoulders, and tighten the middle with a clamp.

In the slipway, the onion should dry for about a week, after which it should be removed and the ends of the onion should be drawn to stretch the bowstring. You need to prepare a place for horn / bone tips or just cut a "step" for the bowstring loop.

The onion is almost ready. For the longevity of its service, it will be necessary to protect it from drying out or moisture. If there is a need for a historical and reconstructive direction in work, then you can soak the onions with heated wax or molten fat. However, do not overdo it! Impregnation should not be more than 3 mm in depth, otherwise the onion will lose its elasticity), otherwise you can use modern paints, varnish or mastics.

It's time to pull the string.