To the author of this homemade came up with a simple, obvious, but brilliant idea. After all, if you consider that a stepper motor is not only a motor that provides the mechanical operation of completely different devices (from printers to scanners and other office equipment, to various units used in more serious devices). A stepper motor can also serve as an excellent generator of electricity!

And his most important plus in everything is that he doesn’t need large revolutions at all, he can work properly even at low loads. That is, even with a minimal force directed at it, the stepper motor produces excellent energy. Most importantly, this energy is quite enough for various needs, such as lighting a road for a cyclist with a flashlight connected to a stepper motor.

Unfortunately with a standard standard generator bike initial revolutions will still be necessary before the flashlight begins to emit enough bright light to clearly illuminate the path. But when using a stepper motor, this drawback is removed by itself, that is, lighting will be applied immediately as soon as the rotation of the wheel begins.

But the truth is, this miracle of construction will still have a number of shortcomings. For example, the most obvious of them is a large magnetic sticking. But actually it is not so scary for the cyclist.

When getting started, we will need to find some details:

1) Actually the stepper motor itself.

2) a couple of capacitors of large capacity.

3) LED lights

4) voltage stabilizer 5-6 volts.

Finding a stepper motor is quite simple due to the fact that it is very common in all office appliances. The only thing you need to understand is that the larger the stepper motor, the better it is for us.

Here several models of stepper motors and various options for their attachment to an iron horse will be described and presented.

First, take the largest engine that the author managed to get. He dismantled it from a regular office plotter for printing (in fact it is a printer, only several times larger).

Outwardly, the engine is quite large.

But before you begin to study the stabilization scheme of the same power scheme, you should pay attention to the method of attaching this unit to the bike.

If you look at the figure, you will understand that the generator is located closer to the axis of the wheel and rotation is transmitted from the additional circle.

And yet since model each has its own bicycle and someone does not want to damage the frame with self-tapping screws, you will need to develop the mount yourself as well as the rotation circle, there are really a lot of options.

If you can’t imagine how to fasten a large stepper motor to the structure, there is a smaller option:

You just have to choose the option of a generator suitable for the size of your vehicle.

Well, when you figured out stepper motors, you can start with flashlights and power circuits.

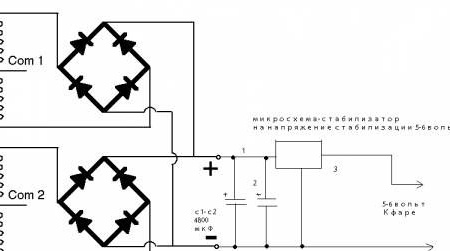

Flashlights must be taken LED. the rectification circuit will look like this: a block of rectifying diodes, several capacitors of large capacity and, of course, a voltage regulator. In principle, this is a standard power scheme.

A stepper motor has four wires that correspond to two coils as standard. for this reason, there are also two on the image of the rectifier blocks. This home-made electricity generator can very well produce up to 50 volts of voltage at high speeds, so it is better to take the capacitors accordingly (voltage above 50). Well, a stabilizer for a voltage of 5-6 volts.

And so what is the essence of homemade work, and why was it needed?

The whole point is in its advantage, even if you just start moving, your path will already be brightly lit by a lantern powered by our stepper motor - it is also a generator.

I would also like to note that during the movement the lamp will not blink or go out - the lighting will be smooth and even.