If you have your own garage, and you are technical savvy, then you can try to assemble a similar all-terrain vehicle "Eber 4x4", and arrange yourself a fun ride on the road.

The main elements used in the construction of the airway "Eber 4x4":

1) The author made the frame for this car on his own, due to his experience in the design of these models, as well as ideas for the operation.

2) The front and rear axles were borrowed from a conventional UAZ with self-blocks.

3) The engine was chosen specific, from Honda. The engine weighs 185 kilograms, which is pretty good at 120 horsepower. It was taken along with an automatic transmission. (this is the extraordinary ease of management in this model compared to conventional all-terrain vehicles)

The differential was brewed inside.

4) a four-link suspension with shock absorbers was used.

5) The low pressure TREKOL wheels were also taken (such wheels make it possible to ensure the all-terrain vehicle's ability to overcome water barriers like rivers / lakes)

6) The hydraulic power steering was borrowed from the Mitsubishi Pajero.

In the images below, you can see the suspension of the front axle of the future all-terrain vehicle:

And here is a four-link suspension on shock absorbers

The whole suspension looks something like this:

Pay attention to the design of the rear four-link suspension

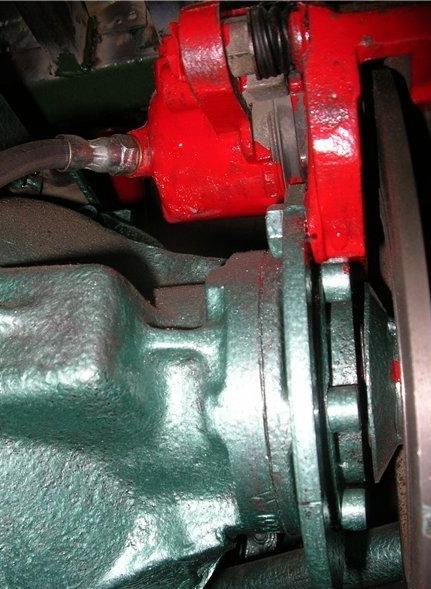

Also, the brake system on the shanks was used in the all-terrain vehicle, it can also be seen below in the photographs

Actually, the image below shows how the springs were mounted for the rear and front shock absorbers

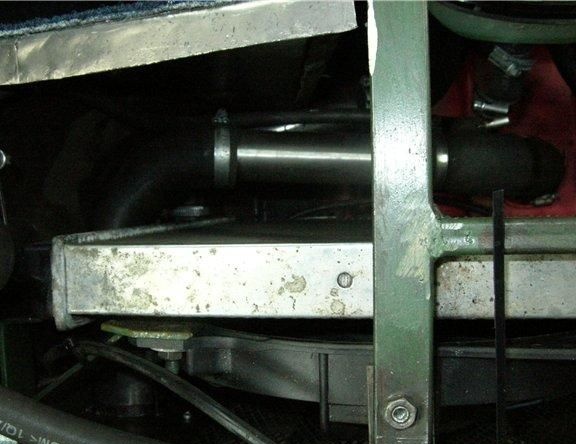

And here is the power steering previously owned by Mitsubishi Pajero, and now faithfully serving for ease of control of the all-terrain vehicle Eber

We thoroughly approach the installation of the winch, in order to still be able to pull out our car in unforeseen situations.

Then they took the hub from the UAZ and independently increased its length by about 5 centimeters. This was done in order to win the corners and the width of the turn.

Tanks were attached as follows:

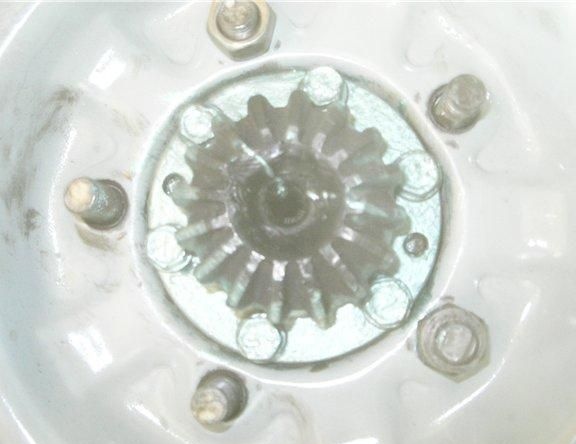

I would also like to note that the calipers on the crankcase were fixed as follows:

A pancake was screwed through the stuffing box cover with the help of through bolts, but the caliper was attached to the pancake itself ...

Then the author took and remade the CV joint, the result is shown in the image:

Another important remark: the bipod was cooked as follows. The author made deep chamfers and welded evenly, so that the seam was heated proportionally (this can be determined by the uniformly distributed red color along the seam). then let it cool gently. Thus, the design will be very strong, and you will not have problems with this in the future. The only remark is that the inspection will be able to pass vryatli.

Also, the author redid the drives in this way:

You probably noticed the painting. How perfectly she lay down without drips.

This is all thanks to a special hammer paint, with its help it can be perfectly painted even on rust in a couple of layers. Such paint is freely sold in stores, and costs about 250-400 rubles per can weighing 400 grams.

Leather anthers are just dust free since the CV joints are non-native. also pay attention to the anthers, they are made of leather since the CV joints are not native, since the all-terrain vehicle was assembled from parts of various cars.

The distance from the gearbox housing to the housing of the CV joint rotation is only 4 millimeters, this is not enough to fit a normal rubber boot, which is why it was decided to install it from leather.

Previously, anthers were generally impossible to find on the market, so they were made independently by taking several layers of ordinary tarpaulin and soaking in grease. Such anthers withstood any frost and did not burst.

The retreat is over, let's proceed to the analysis of our all-terrain vehicle and the work done.

Thus the exhaust pipe was made:

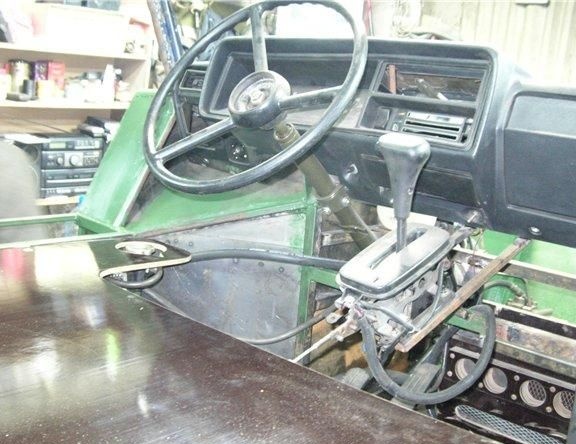

The speed selector for this all-terrain vehicle was also independently installed:

As you can see, the all-terrain vehicle gradually began to take on its future appearance.

We proceed to install the stove and various tanks for liquids (whether it is grease, etc., etc.)

It looks like when viewed from the side:

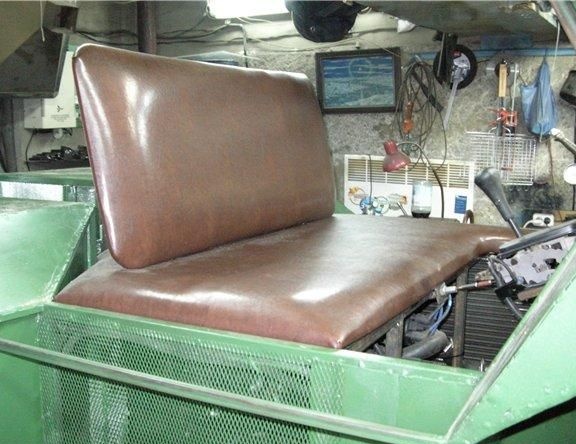

So that the loin portion would not freeze to the frame, and there were no bruises, it was decided to install a seat (like a minivan) and a back for it.

Seen from behind it will look like this:

Another side view photograph.

Jellied box and photo report on it:

Here, the fastening of the battery to the Eber all-terrain vehicle is well shown.

Due to the compactness of the engine and its packaging, excellent access will be provided from all sides, which will allow manipulating it directly in the field in case of unforeseen breakdowns and force majeure situations.

Having finished the mechanical part of our almost finished off-road vehicle, we can proceed to the external decor, namely the installation of the casing. Sheathing was made of rubberized carpet. For fixing, glue number 88 was used, you can also find it in any construction / automobile store.

On this air passage Eber 4x4 was completely completed and ready for field trials. Below are a few videos with the all-terrain vehicle in the title role:

This is one of the first climbs on this all-terrain vehicle.

So he behaves on a snow cover, by the way a speed of about 25 kilometers per hour.

Thanks to its lightweight construction and special wheel, the Eber all-terrain vehicle feels confident in water and overcoming water barriers.

The marshland is also easily amenable to the onslaught of this machine.

We overcome a small rivulet:

The author notes that despite the unsinkability of this model, there is no question of any normal control on the water. Your course and direction of movement are strictly commanded by the wind. In the future, it is planned to mount the blades in the design, maybe this will change the situation on the water.

it is also noted that the automatic transmission from Honda has proved to be excellent, the ease of control just rolls over.

This concludes the detailed review of the unit called the pneumatic pass Eber 4x4. As can be seen from the post, although the collection process is time-consuming, but the ease of management and patency are worth the effort spent on it.

We thank the author and creator of this miracle machine "Gad" and from the city of Novy Urengoy.