On a summer cottage or in a personal household, you sometimes have to do stovework yourself - lay down the stove, make a fireplace. In modern times, hiring a stove maker is an impermissible luxury, especially if you yourself know how to work with your hands.

However, the master stove-maker is waiting for a lot of tricks during work. The main one is that in any stove, as in any fireplace, not only full-size (whole) bricks are present, but also parts of the whole brick - halves, quarters, etc. The kiln laying manuals describe a method for splitting bricks with a pickaxe, but the trouble is that this technique has been used for a long time when bricks were of high quality, without cracks. Now it’s almost impossible to split a modern brick into the parts necessary for masonry, since it will either crumble into crumbs or crack where it is not necessary, and even with uneven split surfaces. And if during the laying of the walls these bumps can be filled with mortar, then during the construction of the furnace this cannot be done, since here the thickness of the joints between the bricks should be minimal (3 ... 5 mm). How to get out of difficulty?

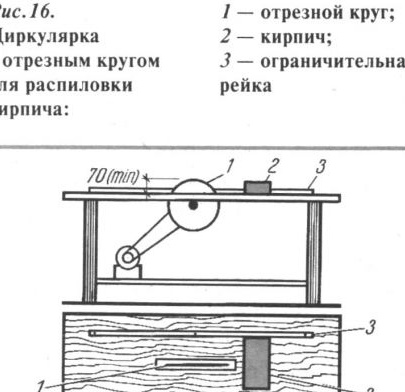

And the usual circular tool helped me - a stationary power saw for sawing timber. I removed a circular saw blade from a circular tool and replaced it with an abrasive fiberglass reinforced circle, which are widely used for cutting steel and are sold in every hardware store. On my circle is the marking K480STZB, but any other will do.

The cutting part of the circle should protrude above the table surface by at least 70 mm, since the thickness of the brick is 65 mm (Fig. 16). But you don’t need to put too big a circle, because during work he will “walk”, that is, bend from side to side. I work on such a circular as usual. I set the size I need with the restrictive rail, turn on the machine and slowly bring the brick (red or refractory) to the rotating circle. Only during the entire cutting process, especially make sure that the brick is constantly pressed against the boundary rail, otherwise the desired size will not work.

As a result of the cut, a perfectly smooth surface is obtained, and the remaining part of the brick can also be used, since it remains intact and does not crumble, as with blows with a pickaxe. Similarly, they cut a brick at any angle.

When processing bricks on a circular, the following rules must be followed:

■ work in the open air, since in this case a lot of brick dust is emitted (if you cut a wet brick, the abrasive wheel will clog);

■ it is advisable to protect the respiratory organs with a cotton-gauze bandage or, better yet, with a respirator;

■ cut brick in glasses (protective). In a similar way I cut asbestos-cement pipes and sheets, cast-iron parts that are used for laying furnaces, and any metal, including corrugated aluminum roofing sheets. The edge is smooth, not deformed, as when cutting with scissors. Fast and convenient.

I think my advice will come in handy for masters, and maybe stove-makers.