The English wheel is a machine for processing metal sheets up to 2 mm thick. It is mainly used in the field of restoration of the bodies of old (retro) cars and for creating original parts for “custom” motorcycles. To this adaptation for more than one hundred years, it was widely used in Europe in the twentieth century, but it gained the greatest popularity in England, where its name came from.

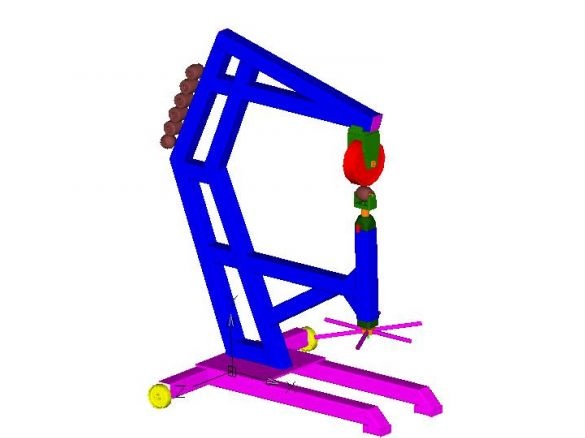

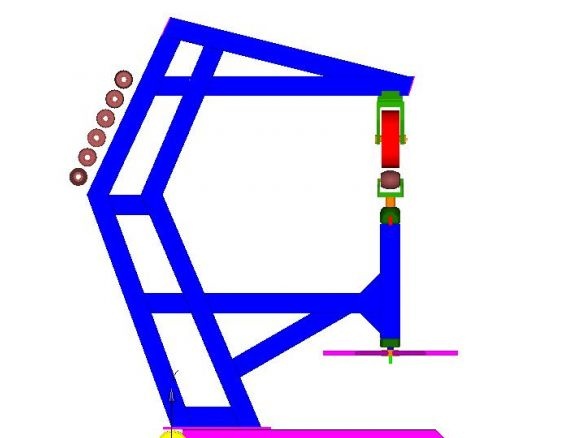

The design of the English wheel is quite simple - it consists of two metal rollers connected by a rigid frame, between which a sheet of metal is rolled. All machines are approximately the same size and are divided into desktop and floor, while they have a rigid fixation to the surface on which it stands, because when working on them there are strong vibrational loads.

The frame of the machine must have very good rigidity to prevent it from bending when passing metal between the rollers.

Material and tools that will be needed to create the machine:

- Standard tools such as grinder, drill, pliers, ruler, etc.

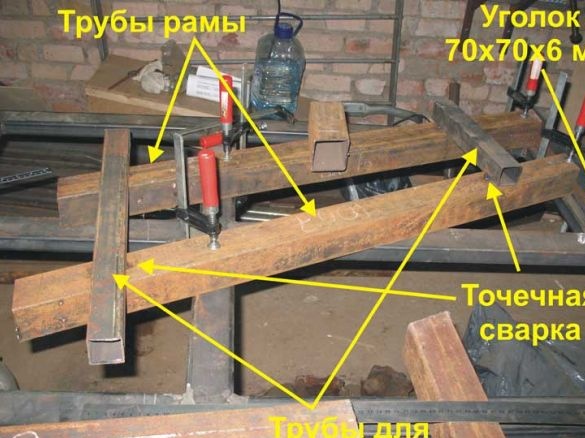

- Profile pipe (size and length depends on your project)

- Welding machine (semi-automatic)

- Welding table or similar device

- The project also has a lot of turning work

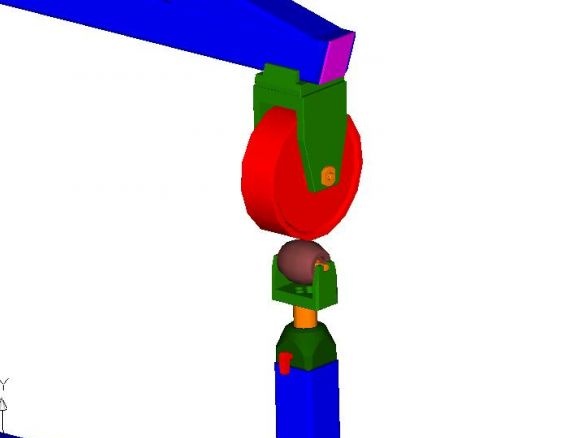

The machine usually has a whole set of different rollers for work, which you can do yourself, you can order ready-made abroad. The upper roller is large, cylindrical, has a flat contact surface. The lower rollers have different radii of curvature of the surface, from almost round to flat. The bending of the workpiece profile depends on the selection of the roller.

There are also creasing rollers, for bending stiffeners on metal, they also come in various shapes.

The rollers of the machine must be heat treated, since they must be harder than the metal of the workpiece.

Bearings are installed inside the rollers to increase the service life.

The pressure of the rollers is regulated by a special screw, which is driven by the helm at the bottom of the machine.

In this project, there is a built-in leather cushion inside which is sand. It is called a “kraftformer,” and is needed for the initial rough fitting of parts, for example, bends of a motorcycle wing or parts of a gas tank.

On the opposite side of the “wheel” you can install a rack for various anvils, they will be needed to work with the faces of the workpieces.

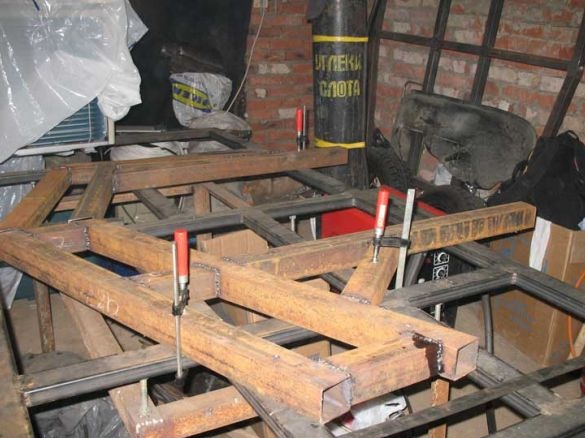

An ideally suitable welding table is suitable for assembling the machine, but since not every one has any extremely flat and hard surface (you can weld it from corners or profiles) to which parts of the “wheel” are clamped. When setting the parts to be welded, it is important to note the zero coordinate, this can be any piece of the corner from which all the profile tilt angles will be measured.

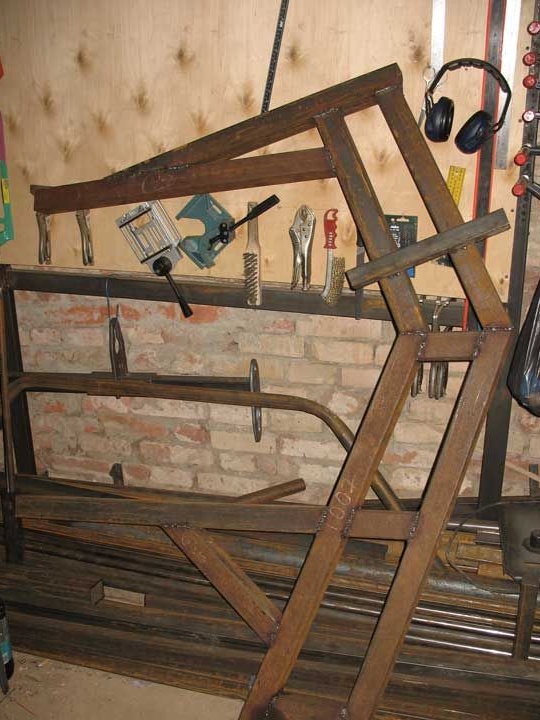

Here is the result: