The article describes the manufacturing process. fixtures for shortening motorcycle spokes, as well as the technology of its work. This information will be useful primarily to people who are engaged in customizing, that is, they themselves collect motorcycles on their projects. Such spokes may be needed in the manufacture of rear wide wheels on a motorcycle, which have gained great popularity among

"Chopperists."

The need for this device is determined by a small assortment of finished motorcycle spokes in the CIS. When trying to make knitting needles from scratch rather than shortening motto builder you may encounter a problem with the thread on the spoke, since in the original the thickness of the thread is greater than the thickness of the spoke, and finding suitable blanks can be very problematic. Also, factory knitting needles have knurled and not cut threads, which improves its quality. Therefore, it will be more correct to remake the finished knitting needles than to make new ones, especially since this project does not require special costs and is very simple to manufacture.

For the manufacture of tools you will need:

- A single piece of metal, size 20x40x100mm;

- Two m8 bolts, 60mm long and “wing” nuts for them;

- Drills with a diameter of 8; 4,5;

- drill;

- The big Bulgarian;

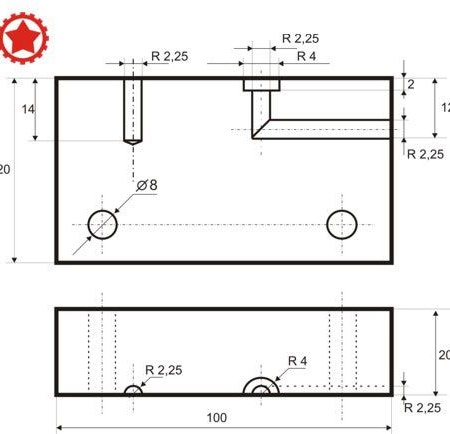

Here is a detailed drawing of the device, as you see nothing complicated.

The process of working with the device:

Stock knitting needles are prepared, the necessary length is cut.

Then the needle is inserted into the hole on the fixture and bends at the desired angle.

Two halves of the devices are untwisted, the spoke is inserted with the curved side into the grooves, after which the adaptation is assembled again, already with the spoke inside.

There should be a hat in place of the protruding short tip of the spoke, for this it must be riveted. When riveting the spokes, gas welding is used, the end of the spoke is heated to red, and then riveted with a hammer. Such work requires experience, so the first time it may not work.

Next, the needle is removed from the device, and the hat is processed on a grinder or sandpaper. Then the spoke is ready for electroplating.

The author of the article claims that such knitting needles come in quite good quality, perhaps only slightly worse than factory ones.