Pipe bending machines have a very wide scope: they bend pipes for laying communications, for production of furniture, blacksmithing, are also widely used in mechanical engineering. The cost of factory machines is quite high, so if you need it, it makes sense to do it yourself. In the article, the author talks about creating a roller bender. The choice fell on him due to its versatility.

The construction of such a machine requires turning and welding

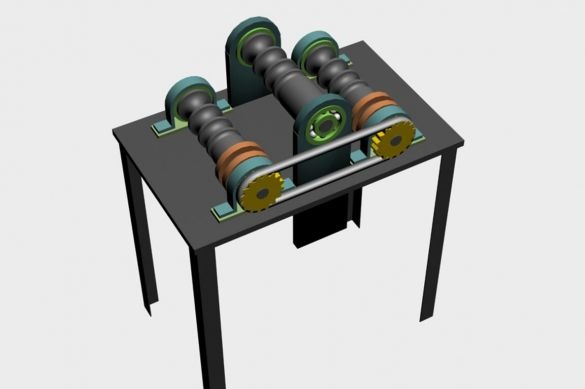

The project begins with a 3D model drawn in 3DMax. The object is drawn in real size.

At the beginning, the plan was such that, without changing the shafts, it was possible to bend both a round and a square pipe. But the shafts should have had a length of 600mm and a diameter of 80mm. The author did not find blanks of this size, so he decided to create the design in a simpler way.

The project involved changing shafts for round and square pipes (round in perspective).

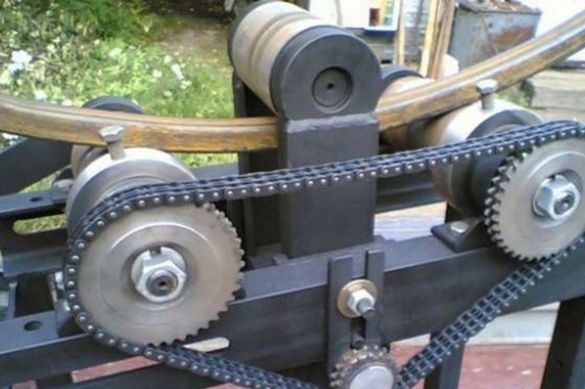

Both stars and a chain were used from the camshaft of the Moskvich automobile.

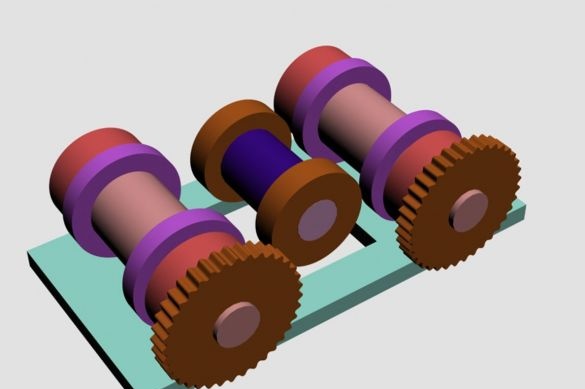

Six bearings were purchased and shafts were machined:

We make a carriage of a clamping shaft. To do this, we use a 30x4 metal strip, crescents are bent out of it, bearings later sit in them.

Using metal with a thickness of 12 mm, an “U” shaped carriage is assembled. From the outside, 10x10 squares are welded, which serve as guides. On the inside, scarves and bearing seats are welded.

This shaft mount design makes it easy to remove and install different shafts.

With the awareness of the body, the author paid special attention to the possibility of transportability of the machine, and tried to make it as small and light as possible.

4mm thick iron sheet is marked.

Crescents are pressed and welded:

From the 30x4 metal strip, the guide carriages of the pinch shaft are welded into place.

In this case, the holes for the shafts were burned by welding.

Carriage in place:

Trial assembly of the case:

The shafts are fixed with a regular metal clamp. The main thing is not to drop out.

We’ve finished with the case. It remains to come up with a mechanism in the upper part of the machine, which will create the necessary effort on the carriage.

It was decided to use a screw with a tool thread. A screw with a diameter of 30 mm was used here.

A support bearing is needed between the carriage and the screw.

To fix the bearing, a suitable piece of tubing was found and welded to the center of the carriage.

Washers are welded to the end of the screw:

A slot is made in the tube and an impromptu cotter pin 1 mm thick is inserted into it.

In the upper part of the body, a hole for a screw is burned by welding, a nut and stiffeners 4 mm thick are welded.

Holes for the cotter pins are made in the sides of the cover, for which the cover will be attached to the side parts of the housing.

Ears with drilled holes are welded to the side cover. They will serve to secure the side of the case.

In the counterpart, we cut the m8 thread.

The case is assembled!

It remains to attach the drive to the shafts and install stars on them. To do this, the shafts at the edges are slightly ground.

And stops are welded to the gears in size:

Now you need to install the tensioner. Under the inner diameter of the timing belt tension roller, a bolt is selected and welded in the right place.

The handle of the mechanism is made of a key 20/22. A suitable nut is welded to the gear. The key is put on the nut and fixed with a bolt.

And the finishing touch: machine mounting tabs:

Here is the finished machine after painting: