As standard, such Soviet motorcycles how Dnepr or Ural start up only with kickstarter. And if the engine works fine, it starts with two to three pokes, kickstarter is enough. But still, many motto owners would not mind modernizing their horses by adding such an assembly as an electric starter to their design. It gives the motorcycle a more modern look and simplifies the process of starting the engine. Moreover, structural changes in the crankcase are minimal and the refinement itself is not so complicated.

Parts List:

- Starter from a motor boat "whirlwind" or a car "Cossack";

- A crown for the starter;

- A metal plate of fastening of a starter;

- Drill, grinder.

Also, for the starter to work, you need a more powerful battery than a standard one. It is recommended to use batteries with a capacity not lower than 18 ampere hours.

You need to start with the installation of the crown.

To do this, the box is thrown off the engine and six bolts holding the clutch discs are untwisted. The crown is installed instead of the last disk. The size of the crown is slightly larger than the size of the disk and it will interfere with the installation of the box in its place. There are two ways to eliminate this: The first is to shorten the fingers on which the clutch discs are held by 3 mm, the second is to cut the guide boxes protruding from the crankcase.

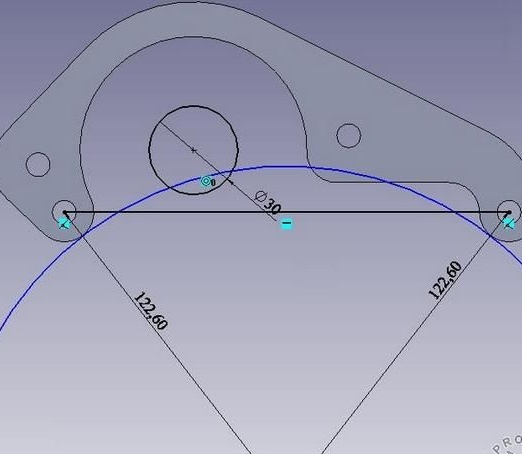

Second stage will be manufacturing starter mount plates. This plate will be attached to the two upper pins, for which the gearbox holds. Three holes are drilled in it - two for fastening the starter, one for attaching to the studs. The second hole is best drilled with an exact fit of the starter to the teeth of the crown.

Here's what it should look like:

Then, in the engine crankcase, a hole for the starter is cut out by a grinder. Through it, the starter will interact with the crown. It is cut out on the box and on the engine separately, after which the box is put on the engine.

Next, from the starter, you need to mechanically extend the twisting ring gear. The easiest way to do this is by removing the retractor and pressing the lever there.Then the starter is installed in place, the gear stroke is checked. It should freely move forward - backward, while being in good contact with the crown when extended. If the gap between them is too large, this will entail increased wear of the teeth, and if too small - unpleasant sounds when starting the engine. When the starter has found its place, the remaining hole for the hairpin is marked and drilled. All bolts are tightened, starter in place. Next, a test run of the engine is carried out.