Good afternoon, dear readers! What is the purpose and function of key rings? Well, firstly, it outwardly adds beauty and style to your keys, but key rings also perform an important function, namely, they reduce the likelihood of losing keys by the owner. Today in this article I want to tell you about how you can yourself in home conditions to make a metal keychain World of tanks, which outwardly will not be inferior to the same trinkets purchased in specialized stores.

To start, I want to suggest you watch this video homemade from the author:

So, as we understood from the video, the author will show us the process of manufacturing a keychain for brass etching using chlorine iron using the example of the logo of the computer game "World of tanks". Usually, ferric chloride is needed to make circuit boards.

For crafts we will need the following components:

- ferric chloride (you can purchase it on the radio market or in the store of radio goods);

- Vinyl film applique (in our case, this is a logo of a computer game);

- latex gloves;

- protective glasses;

- scissors;

- tweezers;

- plastic container;

- soft brush or brush;

- pliers;

- files, files, sandpaper;

- ammonia;

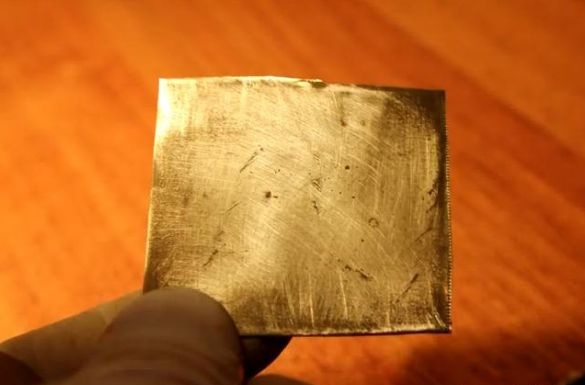

- a piece of sheet brass or bronze;

- sealed container with a lid.

So, we put on gloves and get to work.

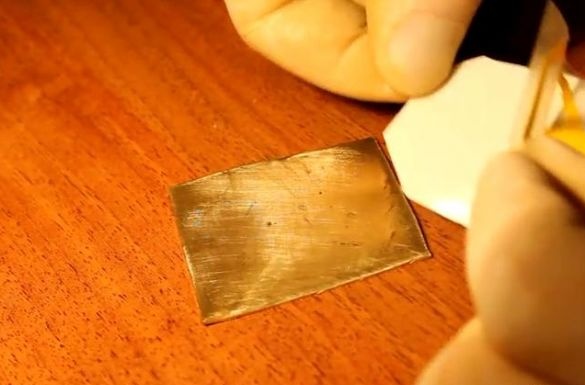

First you need to prepare a vinyl application. Next, carefully apply the mounting film to it and level it:

If you do not have a mounting film, then you can easily use molar tape.

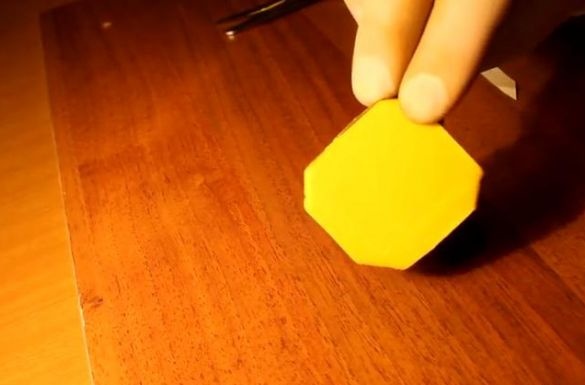

you should get such a blank here:

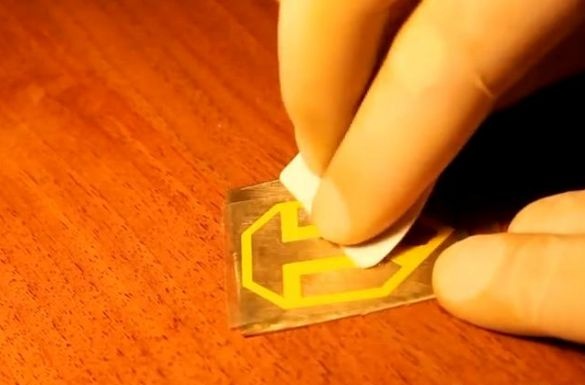

Now you need to carefully transfer our application to a piece of brass:

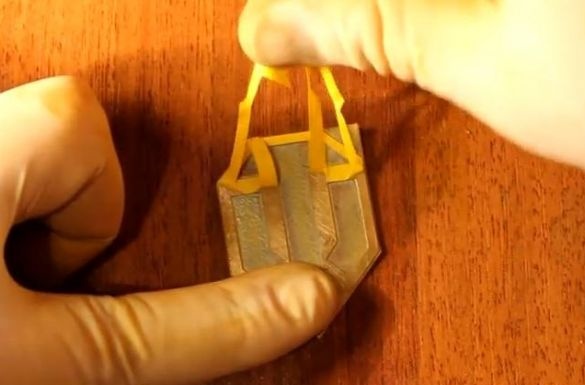

Using pliers, you need to carefully bend the corners of the brass billet at 90 degrees like this:

These bent corners play an important role in the manufacture of the finished product. Since we will lower the brass face down (to the bottom of the tank), the corners will play the role of “legs”, that is, the solution will wash the front side of the brass.

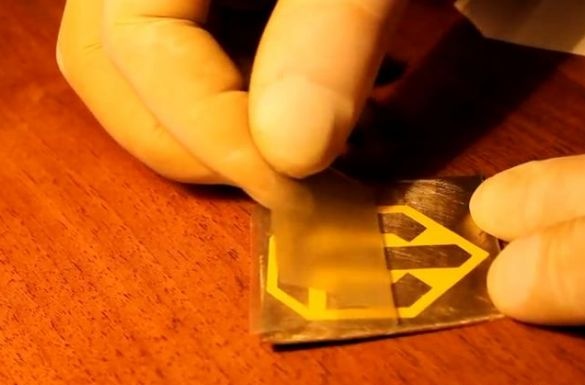

The back of the brass also needs to be protected from the etching process. To do this, you can seal it with vinyl film, tape or varnish.

We are preparing a solution. To do this, pour water at room temperature into the tank:

Gently add ferric chloride to the water and stir the mixture until the consistency and appearance of the solution resembles ink:

Next, carefully place the workpiece face down in the solution, making sure that there is no air between the workpiece and the bottom of the tank. We are waiting 10-15 minutes.

After the time has passed, we remove the workpiece and see that the etching process has begun, since the workpiece has become rough, gently wash it under water and lightly wipe it with a soft brush or brush:

Now we stir the solution and again in the same way we place the workpiece in the solution for 15-20 minutes. Next, rinse the workpiece again with running water:

We carry out such operations for a total of approximately 2 hours, and then we pull the workpiece out of solution:

We cut off the unnecessary parts of brass and remove the vinyl film from the workpiece (we leave one corner in order to make a hole for fixing the keys):

Now we’ll “arm” ourselves with files, files, sandpaper and grind the product carefully from all sides so that it has a “presentation”:

After thorough processing of my workpiece with detergent and clean it from dust and dirt. Now you need a little "toned" workpiece. To do this, pour a little liquid ammonia into the container, put the billet there, close the lid and place it in a warm place (for example, a battery):

After about 40 minutes, we get the workpiece:

Now polish the workpiece. Tooth powder is perfect for this:

Pour the powder onto the workpiece and carefully rub the workpiece with a finger or paper towel. Next, we wash off all the traces and you should get such a blank here:

After that, we outline the place with an awl and use the drill to make a hole for securing the keys:

Now we put on the mount and that's all! Our keychain is ready!