Mikhail from Perm with his friend Alexander developed an unusual model triaxial all-terrain vehicle with a loud-speaking name "CONTROL". In general, the idea of building an all-terrain vehicle was proposed by his friend Alexander, but Mikhail was engaged in basic changes in the design, their modernization and also put a lot of effort into this car. The concept of the all-terrain vehicle is unusually pleased, as conceived by the authors all-terrain vehicle will not be an ordinary swamp, but will have many layout options and types of drives, and all this should happen with minimal alterations in the design. During the construction was considered primarily side-turn option or front wheels are steered, and tracks are placed on the rear axles. The all-terrain vehicle has rear engine placement. two leading axes: the first and third.

What I wanted to achieve:

1. The all-terrain vehicle must be able to swim, and therefore have a boat type hull. It is long 3400-3600 mm. width 1600-1800 mm

2. The ability to carry loads of 500-600 kg.

3. Stir in up to 6 people.

4. Have a high speed of movement (70 on unpaved surfaces).

5. Possess excellent passability, so that it is easy to get to hunting / fishing.

7. Use only completely factory-made components and assemblies in the device. (No boiled drive joints for drives and homemade universal joints, the part is broken, I bought a new one and put it back in line 4 hours later.

9. It should be light no more than a ton.

10. Keep within the budget of about 250 tons

Materials that were involved in the construction of the all-terrain vehicle:

1) Sheets from the UAZ spring.

2) Tires Trelleberg T411 29x12.5x15

3) Engine from frets Viburnum 1.4 (mileage of about 5000 kilometers)

4) Automatic gearbox 3-speed Opel Record. 1992

5) Steering column Niva 2121

6) Uaz military bridges.

7) A 20x40 pipe will be used for frame welding, which will be sheathed by sheet aluminum as a result. Those base type NIVA 2200 mm.

Read more about the steps of assembling an all-terrain vehicle with photos and illustrations.

To begin with, it was decided to take up the frame of the future all-terrain vehicle. As you can see from the picture, it was done independently:

After mounting the bridges, we started installing the drives:

And here comes the fitting of the all-terrain vehicle wheels:

In the photos below you can see the angles of rotation of the wheels:

So far we decided to stop on the rotatable front and rear axles.

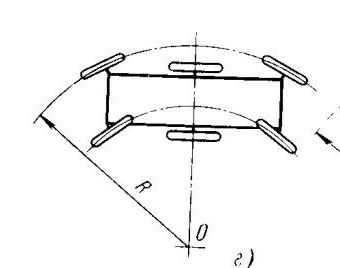

One of the author’s comments was that when controlling the front axles, there is a greater need for inter-axial differentials, however, using a similar scheme, the difference in the path between the axles during rotation will be minimal and it is quite possible to do without differentials.

Here is a diagram of the trajectory of the turning radius of all six wheels:

The width of the all-terrain vehicle on wheels is 2200 mm, and the wheels themselves are quite small in width only 317 mm.

Here is a video with a good example of how the axis rotation mechanisms work:

With engine installed:

In order to directly see the difference in wheel slippage, markers were put before rolling out. According to the results of the tests, it was revealed that with full inversion, the difference between the front and rear outer parts of the wheels is half a turn of the wheel.

After checking the maneuverability, the authors proceeded to install the steering. In the photo below you can see the steering shaft support, a connecting rod from the classic was used:

springs were cut about 3-4 centimeters. At the ends of the sheet, holes were made for mounting the plates under the ball, the springs were drilled without problems:

a support was made, which was reinforced additional, so that the bend in the middle of the pipe was no more than 1-2 mm. In fact, it is selected backlash in the support.

We installed the clutch, the backstage with the inclusion algorithms as in the classics:

Regarding bridges, in contrast to the cornfield, 2 right grenades are used here, respectively, the distance between the ball joints is greater due to the difference in the length of the grenades. To begin with, the upper levers were mounted, and the distance between them was measured in the field, plus an adjustment for the length of the grenades. And only then a fist was hung on the lever. It was set vertically and each spring was applied. Then the collapse was verified and parts were adjusted.

Then the pedal assembly and steering were exposed.

After the final installation and steering adjustment, the guys proceeded to trim the all-terrain vehicle:

Rear:

Front view:

Work with aluminum is almost complete:

Super dashboard!

Put the seats:

One of the first field trips, work on the hull has not yet been completed:

They made an injection, let the wings back, clutch and brakes:

Then the authors engaged in the manufacture of tracks for an all-terrain vehicle on two rear axles:

Ready-made all-terrain vehicle on tracks:

Close-up:

The authors of this car are Andrew with the nickname Sanha and Mikhail "mishanya68".