Another variant of a pneumatic all-terrain vehicle called Vogul. This name is all-terrain vehicle takes from the river Vogulka, on which the author often rests. the maximum speed of this all-terrain vehicle on an acceptable highway can be up to 60 kilometers per hour. The all-terrain vehicle was built for specific conditions, and in particular for movement along wetlands, logging winter roads with ruts, despite the fact that there are no real swamps in the vicinity of the author's residence, so the floating properties of the all-terrain vehicle were not a priority. The objective was still to create a fairly comfortable car for off-road driving, as well as with the possibility of spending the night in it (the car should have at least 2 berths), with long-term outings for hunting or fishing.

The following components and mechanisms became the main components for assembling the all-terrain vehicle:

1) the chassis was removed and upgraded with Suzuki Escudo

(That is, it includes both bridges, the frame itself, the transfer case, power steering, and of course the universal joints).

2) An internal combustion engine from Suzuki Alta, an injection three-cylinder, with a capacity of 54 horsepower.

3) A three-speed automatic gearbox was removed from the same Suzuki.

4) As for rubber, tires from Kraz were taken and stripped to reduce weight. (As a result, the weight of the wheel assembly was about 54 kilograms)

Let us dwell in more detail at the stages of construction of this all-terrain vehicle. And for starters, we immediately indicate why this time the author decided to build an all-terrain vehicle already on a finished frame, and did not create it on his own.

The fact is that the author of this car does not have such serious experience in designing, so he considered that using a ready-made factory version, time-tested, would be more reliable than trying to assemble the main structural element of an all-terrain vehicle on its own. But for reporting, the size of the frame profile in its middle part was measured and it was about 110 mm by 50 mm.

The author decided to abandon the multiple use of canisters for long-distance trains, so he made a car tank capacity of 55 liters, this is enough for almost any sortie with a margin, while the weight of an empty tank is no more than 20 kilograms.

Why did the author decide not to focus on the buoyancy of an all-terrain vehicle? Everything is determined by the territory on which the all-terrain vehicle will be operated, in principle there are not so many places where it may be necessary to cross (the rivers are too steep banks, besides there are crossings that are cut through the rapids).

As already mentioned to the author, mobility is very important, therefore the all-terrain vehicle sometimes must serve as a home for the hunter.

And so we will proceed to the author’s own work on all-terrain vehicles and their photographs.

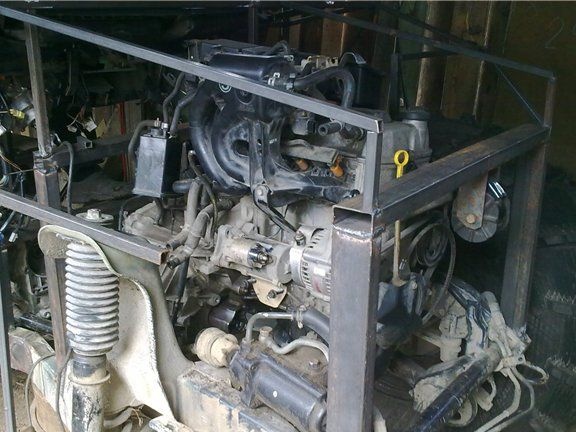

In the photo below you can see the modernized frame from Suzuki, it was slightly narrowed:

And here is the first manufactured disc.

Tubeless under flaring. The locking rings were reversed. Cone rings 1.5 mm. Their mass is 17 kilograms.

Then the author proceeded to try on the tank from MTZ. It is quite close in size to its native fuel tank from Suzuki, but still had to work a bit with a file and grind some corners:

Then, the author began work on welding the filler neck of the fuel tank. Then he decided to install a gasoline pump and paint work:

The next step was to install the engine itself. At the same time, the instrument panel was tried on, and work began on the construction of the car frame:

it was decided to remove the pump from the compressor, as well as to redo the bracket and install a pump for the hydraulic power steering.

The differential directed to the gearbox was brewed, a native, but redone stick drive to the transfer case. Unfortunately, with this design, the SHRUS from Alta will experience a double load, moreover, without the possibility of a momentary reset.

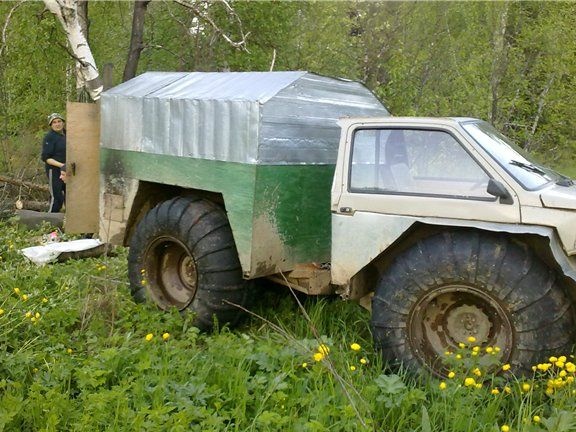

After the final work on the frame, the distance between the wheels was measured, which amounted to about 1180. The maximum external angle from the center of rotation of the wheel was 25 degrees. The width of the frame was 780, everything was done so that the engine was in a stable position and it was not in danger.

After the frame was made, final work was done on the car frame. All welds were stripped. painting work has been done. The wings of an all-terrain vehicle are sheathed in galvanized steel. And the lower part of the all-terrain vehicle was made of moisture-proof plywood, which significantly reduced the weight of the structure. The top, it was decided to collect from a three-layer polycarbonate 10 mm thick.

As you noticed in the design, there is no right passenger door, since the author decided to abandon it due to his reasons, in that part he decided to arrange a food locker. And the entrance will be on the left side, or through the emergency rear exit.

As for the weight of the whole structure, it will be distributed as follows:

1) the chassis will be under 400 kilograms

2) all wheels come out in 200 kg

3) motor and gearbox 110 kg

4) a tank full of fuel 75 kg

5) Sheathing + frame will weigh 100 kg

That is, the total mass of the structure moves to the ton.

After these works, the frontal part was ordered and manufactured, and the glass frame was welded in and everything was installed:

The main wheels were dressed:

What the machine looks like in the final version:

The author also shared his positive impressions of the operation of the all-terrain vehicle.

This model the all-terrain vehicle has a fairly easy control, comparable to a conventional passenger car ("one hand on the steering wheel, the second on the knee"). A huge plus for the convenience of control is an automatic gearbox. There is also a very good dynamics for this all-terrain vehicle. The average speed of movement along the forest belt was 10 km / h according to the testimony of the navigator. Fuel consumption is also quite small, the fuel tank is enough with a large margin.

New wheels were made with a size of approximately 1300 * 580-24. Then continued testing the machine in practice.

Tires were taken from the IYAV-79 Belshin combine. The difference between them is that they are much more powerful. The width of the fit was 25mm. The front ones have four layers, and the rear six. Therefore, the weight of the front wheels is now 30 kg, and the rear wheels are about forty.

Now this all-terrain vehicle may well cross rivers.Although, again, the tires were installed not for the acquisition of buoyancy by an all-terrain vehicle, but more for more convenient movement in the snow in winter. Since the VI-3 still proved to be quite difficult in such conditions. Although buoyancy in the spring, taking into account the flood, will never be superfluous.

This is how an all-terrain vehicle moves through the mud:

Video motion on a flat dirt road:

Fording a river:

Now let's talk about the design flaws of this all-terrain vehicle.

In case of breaking through the tank at the next stage, it will be quite difficult to repair it in the forest. Use the same canister to cover the distance to the garage, also difficult to implement, since a high pressure pump is installed here and it is quite difficult to implant it in a canister.

Another weak link of this all-terrain vehicle is the silumin front axle, as well as weak CV joints, which poorly hold even wheels with a diameter of 29. Therefore, the bridge is likely to break.

Also, when buying bridges, the author was warned that they pricked PM on the trophy. But the author decided to stick to a neat ride. Nevertheless, the tasks and conditions for their implementation are somewhat different than races.

However, after several months of operation, it was still possible to destroy the RPM.

Probably, as I said, tires ИЯВ-79 are great for this suspension. It was decided to reinstall the old tires. The front axle was also replaced. After that, the all-terrain vehicle again acquired mobility and the possibility of operation.

Machine author: Pavel from Yekaterinburg with the nickname "Kardan".