All terrain vehicle It turned out to be very worthy, it has 16 forward and 4 reverse gears, which makes it easy to choose the right range for suitable conditions. And in the snowdrifts, you can even get under way with the 5th gear.

The minimum speed was not measured, but the all-terrain vehicle was barely creeping, but the maximum speed in the 16th gear was about 45-47 km / h. The 16th goes 45-47 km / h. The all-terrain vehicle has 4 seats.

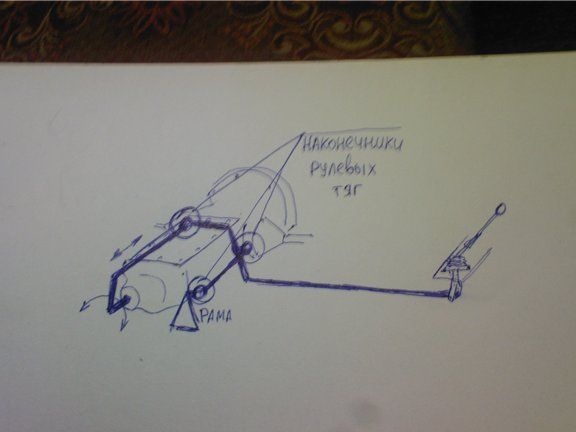

One of the design features of this all-terrain vehicle is the front axle with homemade fists (the design of which will be given a special place in the article) connected 4x4 - 4x4 laterally balanced.

The following materials were used to build the next all-terrain vehicle:

1) IZH-P5 internal combustion engine

2) Transmission from ZAZ

3) Also, a hydraulic clutch was taken from Izh

4) From VAZ a front and rear axle and a hydraulic disc transmission brake were removed.

5) Tires from Kraz peeled to facilitate weight.

We proceed directly to the stages of construction of the all-terrain vehicle.

The main work on fixing the engine and gearbox looked like this: the author took a sheet and welded to it the bearing housing of the input shaft, which was previously turned by a turner. Then he drilled and cut a thread under the grease fitting and boarded up a bearing. The author put the entire resulting structure on the input shaft of the box. The next step, the author marked the holes through which the gearbox will be attached to the engine. After drilling holes, a star was worn from VAZ clutch discs, which fit perfectly on the ZAZ input shaft. After assembling the entire structure, excess contours from the clutch cover were cut off. Below are photos with comments.

This is how the design itself looks from the inside:

But in this way, work was carried out with a standard P-5 cylinder to prepare water cooling:

Then the tires for the all-terrain vehicle were prepared:

By the way, for general comparison, there were two wheel options, the first on tires from the Urals, the second from Kraz:

As you can see from the image, the tire from the Urals is about the same height as Krazovskaya, but already wide, so it was decided to make wheels starting from the width of the Krazov’s tires.

Accordingly, after the tires were prepared and stripped, the author began to manufacture disks:

It is worth mentioning the design features of the location of the engine. It is located behind the frame and goes as if along it, front to back ..From the engine there is a chain to the input shaft of the gearbox from ZAZ (in which, by the way, the differential is welded). One of the CV joints, the author decided to digest under the cross of the VAZ and pass through the disc brake to the rear axle. The brake disc is also of its own design, mounted on the bridge flange and welded.

As for the other SHRUS, the front axle clutch is welded to it, and then goes to the front axle. The coupling was assembled from shafts and couplings from the ZIL gearbox.

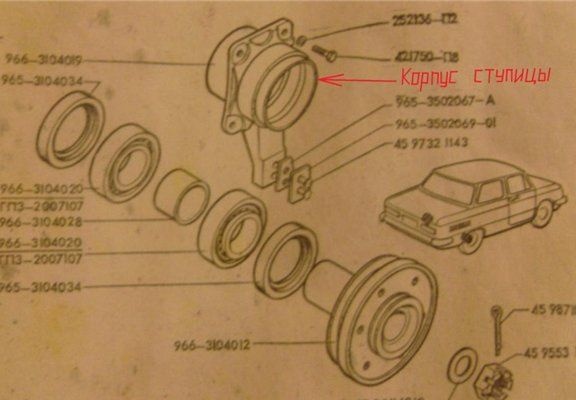

The front axle of the all-terrain vehicle was created on the basis of the front axle from the VAZ, it was reinforced with makeshift fists, as well as the ball from the VAZ, a hub with bearings, a shaft and a cross from the rear drive of ZAZ were also involved.

The entire axle swings on an axis in tapered roller bearings. Thanks to the installed tapered roller bearings, the entire bridge can swing on the axis.

As already mentioned, the fists were the author’s self-made design, so it’s worthwhile to dwell on them in more detail.

1. A seat for the brake drum was cut from the rear axles from VAZ, and a groove was made in the axle shaft under the seat for the shaft from ZAZ. The author did not do these works independently, but ordered a turner.

Although, in principle, with good dexterity, you can do it with a grinder.

Only in this case there are a few little things regarding the work. First you need to remove the semi-axial bearing of the VAZ, this will allow you to reliably clamp and fix the structure. After grooving the axle shaft, the bearing should be driven back, but without the locking sleeve. Since after the assembly of the fist is completed, this bearing is not needed. And in further work, the semi-axis will operate effectively without it.

2. The next step is the welding of the axle shaft with a shaft from ZAZ. And already welded axle shaft can be put on the bridge.

3. Then you should cut off the plate, to which the hub housing is screwed with four bolts, from the lever of the rear suspension of ZAZ.

Then, other plates should be welded to this plate, forming a kind of box from them. As for the plates, the upper and lower ones to which the ball bearings are screwed with three 8 mm thick metal bolts. Side plates are 5 mm thick. After that, you can screw the hub housing to this box, and it is better to make the holes for the bolts a little more. Then, the hub housing is screwed to it. More details about the holes will be described in paragraph 6.

4.Then the outer part of the fist is already worn on a new axis and the bearings are assembled. The hub is put on and the bearing adjustment nut tightly tightened.

5. After these works, you can start cooking on the inside of the fist.

6. And after assembly and welding of the structure, you should loosen the bolts that secure the ball bearings, at the same time rotate the hub and turn the fist in different directions. In this case, a certain combination of the axes of the fist and the cross must occur. After this, it should be noted the position of the ball and remove the upper part of the fist. Then remove the axle shaft. After these operations, it remains only to collect everything back, having previously removed the axle bearing.

With such a fist design, even in the case of small non-mating joints, deviations in work will not be observed anyway, and therefore the mechanisms will not jam.

A single cross was used, and for a larger angle of work, the seats opposite the "ears" were sharpened. The author used a circular saw for stitching. Due to this, even with the wheels fully turned, nothing interferes with the rotation of the structure.

Another design feature of the all-terrain vehicle is that the track of the bridges is the same and equal to one and a half meters, this was achieved due to discs different in departure, however, with this approach it is impossible to replace the wheels from the front axle with the wheels from the rear axle.

Thanks to the use of the ZAZ gearbox, a significant weight reduction was achieved, as well as a general simplification of the all-terrain vehicle design and also a wide selection of gears.

For the backstage, the same operating principle was used as on the backstage from KAMAZ:

In the photo below, front view:

And here you can see the bottom:

During operation, a lot of damage to the all-terrain vehicle was revealed.

But most of them are associated with the physical wear and tear of used parts and spare parts during the construction of an all-terrain vehicle, all of which are associated with the fact that used spare parts are used. But the front axle with homemade fists. who in this article was given special attention, passed all the tests with dignity and without complaints.

Photos of the off-road vehicle:

As you can see the all-terrain vehicle has excellent stability on the water.

The creator and author of the all-terrain vehicle: Dmitry Gorozdey from the village of Pinega, Arkhangelsk region.