Tracked All Terrain Vehicle / tsiplev / - The author and manufacturer of this all-terrain vehicle Vitaly Tsyplev from the city of Vladimir.

Forward to building all-terrain vehicles!

Ready to conquer the vastness of the country.

I started work on my auto-make in November 2013 and now the caterpillar is running and operating in full swing, as can be seen from this video.

But what came before the pile of iron came to life and ran to the joy of those who breathed life into this pile.

Of course, this is an indefatigable desire to create. Create yourself a pleasure, and others surprisingly.

It all started with an audit, which is at hand:

Desired performance characteristics:

1) differential rotation - Gaz-3110 bridge from the Volga, in stock.

2) Volkswagen Glof WV Golf 1.3 engine, in stock.

3) suspensionless, without balancers, pneumatic rollers on the rear hubs of the VAZ-2108.99

4) a caterpillar from a conveyor belt with a thickness of 13 mm, arrived (tape).

5) tracks - almost, like Remix59, corner 32x3, strip 40x4 mm.

6) Track width - 50 cm.

7) Payload - 500-600 kg.

8) The maximum speed according to calculations at 3000 rpm. on the engine - 16.8 km / h.

I would like to quickly, but as they say, it is better to go quietly than to go fast.

Corners and strip are sawn, drilled, what is needed is bent.

Guides for internal fastening.

The dimensions of the guide plates are height.

The dimensions of the guides are width.

Truck in the manufacture.

Track shape selected.

Asterisk leading the first option. The Volgovsky disk. The diameter of the star is 420 mm, 11 teeth, the tooth pitch around the circumference of the disk is 120 mm. Accordingly, between the tracks 88 mm.

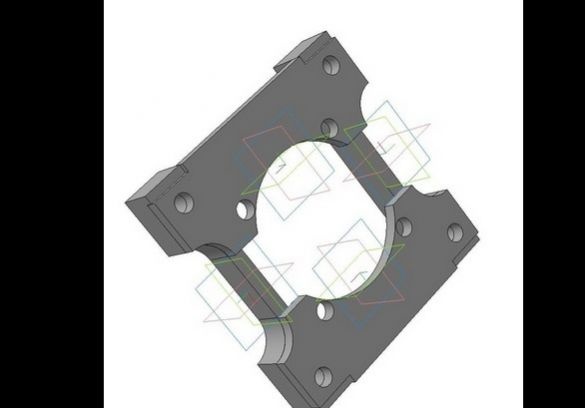

"Adapter" KPP-KPP. At the same time it will be the second bearing for the input shaft of the Volga gearbox.

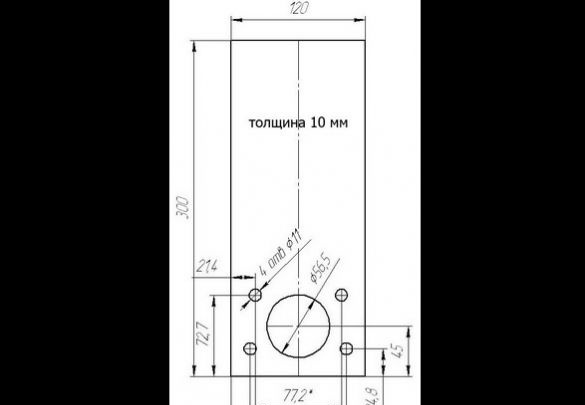

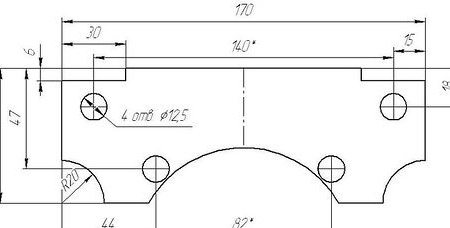

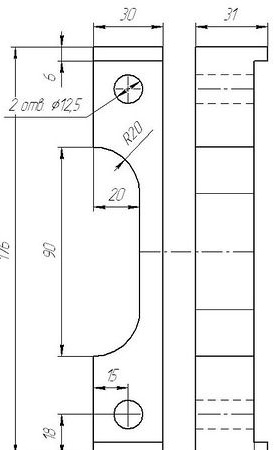

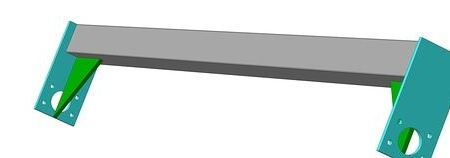

Drawings caliper mounting diagram.

Front view.

Side view.

Ready-made not an all-terrain vehicle.

Caliper details on one side.

Brake discs on a support.

A caterpillar on a drive wheel, an asterisk, checking fit, tooth pitch, shape.

Video.

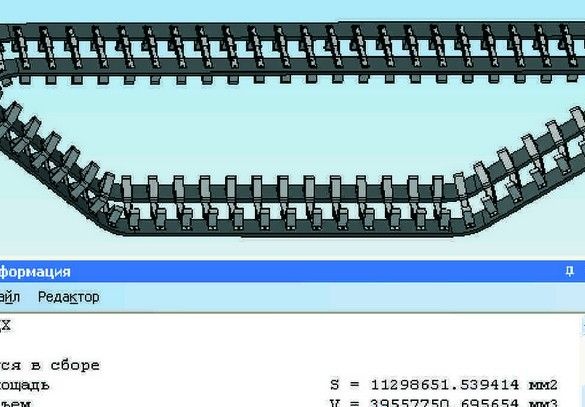

Caterpillar assembly.

The caterpillar on one side is ready.

Drawing of an axis of fastening of basic wheels.

The tension wheels are ready, welded and sheathed with rubber.

Drawing plate for mounting the axis of the support wheel.

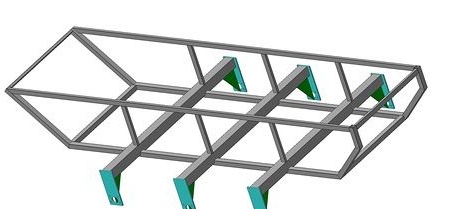

Drawing of the housing with the axles of the support wheels.

View from below.

Side view.

The axles of the support wheels are ready for installation.

The frame is already on wheels.

Installing the engine and hydraulic drive to the clutch.

The brake system is assembled and ready for operation.

Setting the gear lever.

The slack tension mechanism is scalded and strengthened.

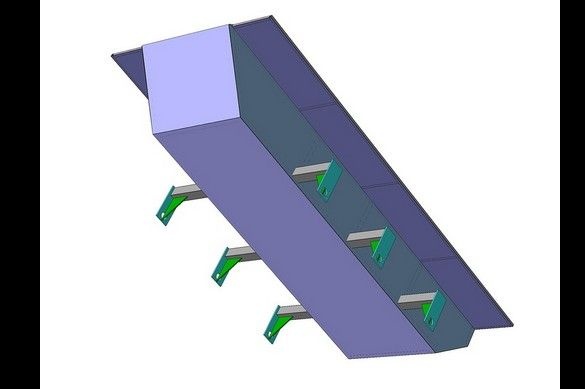

He began to cook the cabin body.

He welded the sides and the exhaust pipe.

Spacecraft control panel (joke).

It takes the form of an all-terrain vehicle in a quiet way.

Side view.

Sheathing sheets are cut and ready for welding.

The future shape of the fuel tank.

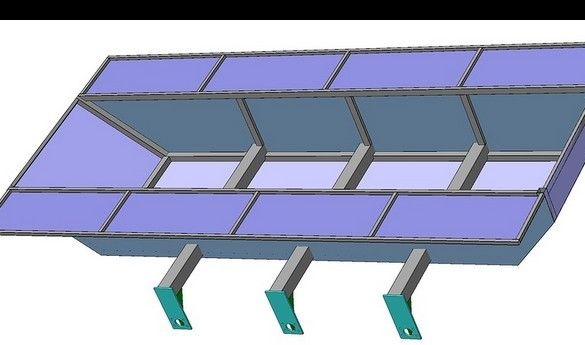

Turned over the apparatus, scalded.

We brewed a cab, at the same time and painted the bottom.

We decided to install supporting rollers.

TTX tracks.

Installing silencers.

Mounted nipples for draining oil from the engine sump for ease of maintenance.

Body and cab painting.

Connect brake pipes.

Connecting brake hoses.

Interior trim.

The first run-in exit.

The caterpillars are bloated.

After the break-in, the fasteners melted.

New muffler and resonator mounts.

I had to remove one tooth from the drive sprocket. Reduce the diameter of the wheel.

Blanks for sprockets.

The second run-in exit.

Mount for hitching a bulldozer knife.

Blade body.

The shape of the knife.

Bent truck after break-in.

Strengthening drive wheel mount.

Of bolts the manufacture of studs.

Work with a dump.

Water tests.

We wish good luck to the team of all-terrain vehicles led by Vitaly Tsiplev.