From time immemorial, fireplaces have been those hearths near which the life of the whole family flowed. A fireplace today is more a symbol of prosperity than an object of necessity, but anyone can create it do it yourself.

Many people, not wanting to burden themselves with extra troubles, spend money on an electric fireplace with an imitation of flame, forgetting that nothing will replace the crack of firewood and the real heat of fire. The cost of construction the fireplace, in this case, will not exceed the cost of the finished factory invention.

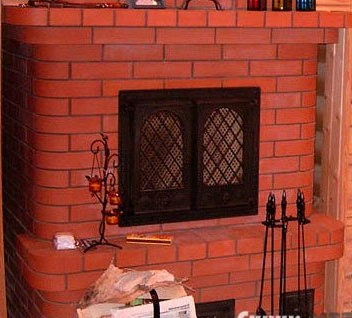

If the owners do not have large financial opportunities, inexpensive, but rather high-quality finishing and facing materials can be chosen for the fireplace. Help out decorative brick, natural stone and wood.

The first thing to do before building a fireplace is to accurately calculate the ratio of the height and width of the furnace, the depth of the firebox, as well as the height of the portal (the proportions of the listed components for the average fireplace are 2: 3, 1: 2 and again 2: 3).

The construction of the chimney, as well as some other parts of the fireplace, will require the use of refractory bricks, which must be chosen correctly, paying attention to its structure and color. Lay a brick or observing the intended pattern, or in random order.

Next, calculate the foundation of the fireplace: the width of the base should equal the width of the base, exceeding the last exactly 5 cm.

The work begins with the creation of a pit sixty centimeters deep, the bottom of which is lined with a layer of rubble (up to 15 cm) and rammed. Then, observing the proportion 1: 3, crushed stone is poured with a solution of cement, sand and water. The upper part of the resulting foundation should be 7 cm below the floor.

A week after the bookmark, you can proceed to the next step. Before starting work, the floor must be covered with roofing material, roofing and insulating material.

Next, each brick of the first row is immersed in water for a while until the bubbles cease to stand out. When the row is ready, it is placed on a solution with a very high cement content.

The walls of the chimney of the fireplace, channels and firebox are wiped with a damp cloth, removing excess cement.In no case can walls be plastered from inside the fireplace.

In order for the rear wall of the fireplace to have an even slope, a special steel screen is walled up in the masonry.

For laying the smoke box and the arches of the fireplace using the method of step inlet.

In order to prevent litter and precipitation from entering the chimney pipe, it is necessary to make curly tin smokers or to cover the pipe hole with a brick. In this case, the brick is strengthened from above with a flat piece of roofing iron.

For the manufacture of fireplace shelves it is better to use processed boards of pine, oak, walnut or cherry. Shelves are protected from thermal effects by a layer of concrete, brick or stone. The shape of the shelves is selected taking into account the design of the fireplace: they can be oval, U-shaped or in the form of a trapezoid.

Repair in the house will be especially joyful if the owners decide to create a fireplace on their own. Such a structure will perfectly warm the room, become non-volatile, will not create noise and will melt very quickly, and you can also implement many design decisions.

Do-it-yourself fireplaces will gather the whole family for many years to share the joy of socializing at the fire.