The author proposes to consider a rather original accessory, in the form of a code lock for a wine bottle. Its outer part is made of copper, and the castle itself has a rather attractive appearance.

Necessary materials and tools:

- copper pipe;

- Brass sheet and rods;

- Copper cap;

- Adapters;

- PVA glue;

- pipe cutter;

- Stamps with letters;

- drill;

- Soldering iron with solder;

- Sandpaper;

- Liquid for polishing;

- Polishing machine.

Step 1.

First you need to choose the bottle for which the castle will be made. Then measure the outer diameter of its neck and make a cylinder of brass sheet using these measurements.

Step 2

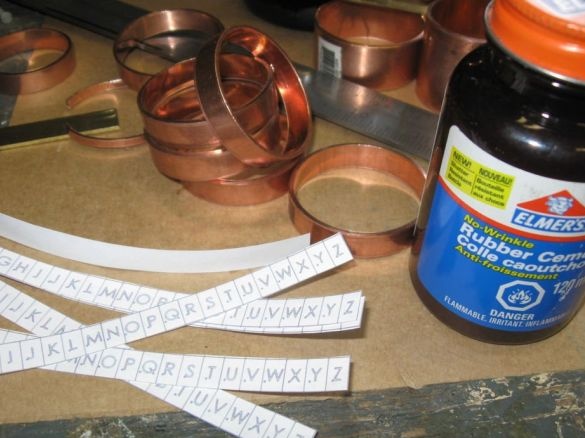

Next, you need to pick up a copper tube, slightly larger than the manufactured brass cylinder. Rings are cut out of it by a pipe cutter.

Step 3

The next step is to create a castle structure. The brass blank is cleaned with sandpaper. After that, strips are cut out of brass along the length of the workpiece and soldered vertically along its circumference through a distance equal to the width of the workpiece. For soldering, you can use a flux with silver solder.

Step 4

Next, a copper plug is made, which will be located at the top of the lock. After the desired size is cut, it is soldered to the brass cylinder.

After that, it must be polished:

Step 5

Stripes are cut out of a sheet of paper across the width of copper rings, on which letters should be written in alphabetical order. Their size is chosen so that they all fit on the ring. They are glued to the rings with PVA glue, and subsequently it will be quite easy to remove them by wetting with water.

Step 6

Then the rings are fixed and letters are punched.

After that, the paper can be removed:

Step 7

The next step is to come up with a code word that should be laid out in rings.

Inside each ring it is necessary to solder a brass strip, so that in the part where the letter from the code word will be, there is a notch.

Step 8

The rings are put on the workpiece strictly in the sequence in which the code word was laid out. After that, they must be cleaned with sandpaper and polished.

Step 9

The lid itself is ready, then you need to make a cage, which will fix the lid on the bottle. It is made of brass strips and smoothly goes around the bottle, bypassing it along the bottom.

Between themselves, the elements of the cell are also soldered with a soldering iron.

Pieces of thick metal wire are soldered to the ends of the cells that go into the lid. They will lock the lock in place until a code word is dialed.

That's actually ready: