In this article, the author describes the process of creating a hydrogen burner in home conditions. The presented device does not have storage cylinders for gas, which makes it quite safe to operate. Hydrogen is produced by electrolysis, and is produced from ordinary water. The gas produced in the required quantities by the NNO generator is immediately burned in the burner, which excludes the possibility of its accumulation and explosion.

Necessary materials for the construction of the burner:

- Stainless steel plates, approximately 1 mm thick;

- Two M6x150 bolts with washers and nuts;

- A piece of transparent tube;

(The project used a tube from a water level)

- The fitting with the "Christmas tree";

(their diameter is selected under the hose from the water level)

- One and a half liter plastic container;

(an ordinary food storage container is suitable)

- Flow-through filter;

(you can use the filter of the washing machine)

- Water check valve.

The tools used are standard, which are available in each workshop.

The first step is to create the heart of an NGO's generator - an electrolyzer. It is made of stainless steel sheets arranged sequentially one after another at equal intervals and bolted together.

According to the source, a stainless steel brand is needed either by foreign AISI316L, its domestic counterpart is 03X16H15M3. But this is ideal, in principle, you can use any.

Why is stainless steel used, and not for example ordinary black metal, because it also conducts current? The fact is that, firstly, ferrous metal rusts in water, and secondly, alkali will be added to the water during operation of the apparatus, which, provided that an electric current passes, will create a fairly aggressive environment for the plates, in which ordinary iron will not last long.

From a sheet of stainless steel, 16 square plates need to be cut. In size, they must be such that they fit freely into the plastic container. You can cut them with a grinder or a jigsaw.

After that, in each plate, two holes are drilled, with a diameter of 6 mm, under the bolts. On the opposite side you need to cut off part of the corner.

Here's what you should get:

Now a little more theory. The principle of operation of the hydrogen generator is based on the fact that when a constant electric current passes through the electrolyte between the plates, the current breaks down water into its components: oxygen and hydrogen.

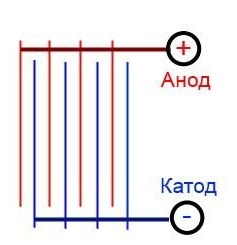

From this it follows that two batteries will be assembled from the plates that are electrically isolated from each other, one of which will receive a plus, the other a minus (anode and cathode).

Here's how it looks schematically:

Such a number of plates is necessary in order to increase the area of electrical exposure to the electrolyte, thereby increasing the current passing through the electrolyte, and as a result, the amount of hydrogen generated.

There are quite a few options for connecting the plates, and this option is not the most optimal. It is used because it is quite simple to manufacture and switch.

This circuit is designed for low voltage and high current.

To isolate the plates from each other, pieces of a transparent tube were used:

The thickness of the ring should be approximately 1 mm.

The plates are fastened as follows: a washer is put on the bolt, then a plate, then three washers, a plate, three washers, etc. So the anode and cathode are assembled, 8 plates each.

Then one battery is inserted into another, turning around 180 degrees. Between the plates, previously cut pipe pieces are inserted as a dielectric.

After assembly, two batteries ring each other, and if there is no short circuit, they are installed in the container.

Holes for bolts are drilled in the container, they will receive voltage.

A hole under the fitting is drilled in the container lid. Before installing the fitting itself, its seat should be lubricated with sealant or silicone. The same applies to the adjacent surface of the lid. To check the container for leaks, it can be lowered into a container of water. If bubbles appear on it, then the container is not sealed.

To increase gas generation, some impurities must be added to the water. Sodium hydroxide, which is found in pipe cleansers, is best suited.

It should be added carefully by connecting an ammeter to the circuit and monitoring its readings.

The power source is best used with voltage regulation, from 0 to 12 volts. The greater its power, the better.

Then it remains to install the check valve and filter. Check valve to prevent gas from entering the container. The flow filter also serves as a water shutter.

The device is ready, it remains to connect the power supply and acetylene torch with a hose.