Often during manufacture homemade it may be necessary to cut a small piece of plastic. Of course, you can do this in all familiar ways, but we propose to make an original knife that will simplify the work several times.

We recommend starting with watching the author’s video

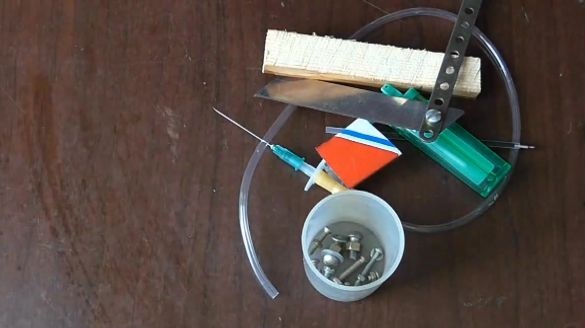

We will need:

- a tube from a dropper together with a needle;

- rod from the handle;

- a small wooden block;

- a lighter with gas;

- bolts and nuts;

- a blade from a clerical knife;

- a little steel constructor.

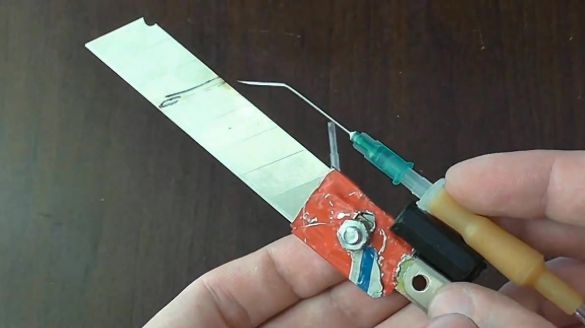

The first step is to fix the blade from the knife between the two strips of the steel constructor. For fixing, a bolt and a small piece of tin are used so that the blade does not hang.

Next, bend the needle by about 45 degrees. The needle and tube must be secured above the blade. To do this, you can cut a small corner from the designer. It is already possible to glue a piece of plastic onto it and fix the needle with the tube on it so that the tip of the needle looks towards the blade.

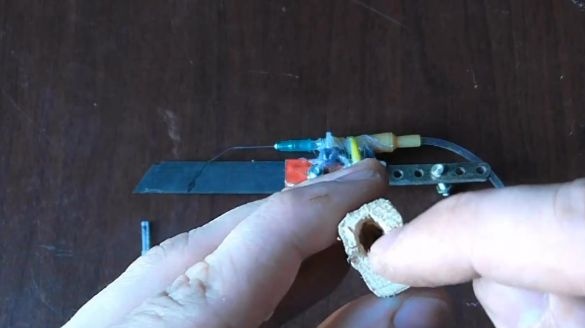

Now you can do the handle. To do this, take a bar and make a hole in it to insert a steel constructor and tighten everything with a bolt.

Also on the side of the bar you need to make a small recess in order to insert a lighter there.

The design is assembled as follows: we insert the blade, fixed by two strips of the designer, into the bar.

Next, we fix the lighter in the side recess and connect the hose to the nipple so that when the button is pressed, the gas passes through the tube. It is here that we need a small segment of the rod from the handle, which is great as an adapter.

If desired, the knife can be painted before final assembly.

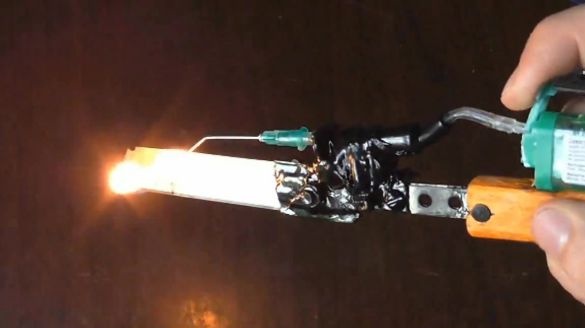

A knife for cutting plastic works according to the following principle. First of all, it is necessary to make sure that the gas passes through the tube, that is, we press the lighter fixed on the knife. Then we set fire to the gas and wait until the blade heats up. After that, you can safely cut the plastic.