In this article, you will learn about an all-terrain vehicle called HELMUT. All terrain vehicle It was conceived as very heavy and powerful, but still on a layout of two axes, which is rather not typical for such sizes. Even at the initial stage of construction, the author understood the gigantic dimensions of his car and hoped to keep within a mass of three and a half tons.

During the construction process, problems arose with engine electronics, for the solution of which the author had to carefully study the documentation. An automatic gearbox was used, and its cooling was realized through a heat exchanger on a “cold” radiator pipe of a ten-meter copper tube twisted in a spiral and placed in a metal case (56 pipe), so there should be enough cooling.

During construction, the following details were used:

1) Wheels k-700

2) Initially, a 2-liter gasoline engine was installed, but replaced with an FD-42 Nisan diesel, 4 cylinders, 125 l / s at 3200 rpm, cr. moment 30.5 kg * m.

3) Accordingly, the automatic transmission has been replaced by a mechanical one.

4) 8 mm plywood and 1 mm thick profiled sheet were used for sheathing.

Consider the steps of assembling an all-terrain vehicle.

To begin with, the author welded the frame, and also set about installing components:

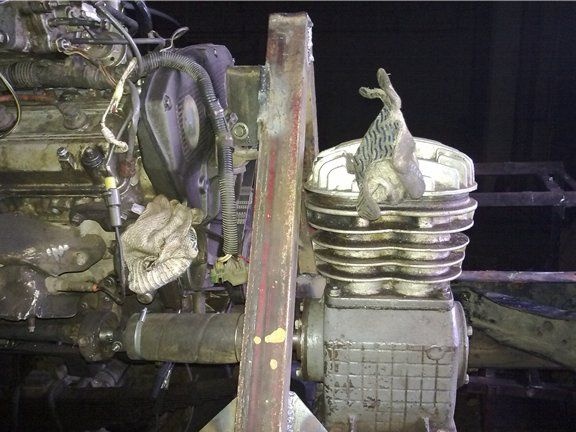

In this image, the universal joint on the compressor from the drive of the right wheel is visible (diff is blocked)

Then the author took up the work of steering an all-terrain vehicle.

GUR native pump:

View from the left front wheel:

First test drive:

When driving in the snow up to 1 meter high there are no problems.

The engine is a little weak for such a colossus, a three-liter would have looked more appropriate. Accelerates to 50km \ hour, high speed greatly affects handling.

There were no problems with the all-terrain electronics.

Here you can see the input of the cardan into the gearbox.

Then the author installed the compressor and finished the gimbal:

car frame installation work:

Installed heat exchanger for cooling automatic transmission:

Here you can see the automatic transmission control lever:

And here is the thrust support sleeve for automatic transmission:

So goes the bend of the thrust after the second support sleeve:

So it was decided to make the connection of the thrust and automatic transmission selector, and the total length of the thrust was about four meters:

Then, work was done to replace the driver’s seat, a hydraulic steering wheel, an automatic transmission drive and selector, a pedal block were installed, and the pneumatic brake system was mounted:

The muffler had to be twisted so as not to creep out from the sides of the frame:

Here is a bottom view of the exhaust system installed on a regular place:

Final work on the installation of cooling:

The radiator was taken from the gasoline "Ural", and the fans from foreign cars.

A test drive was made for a couple of hours. During testing, a number of minor flaws were noticed: the box does not automatically switch, you have to work with the selector, but this is fixable;

the sensor for turning on the cooling fan is not compatible with the computer, but there are two fans and both can be forced to turn on;

but there are more problems with the compressor: there is no full-time flywheel on the compressor shaft, because of the pulsating moment there is a knock since there is a backlash in the drive, which manifests itself at each revolution;

due to the high compressor performance, the pressure regulator from Kamaz is unstable.

To correct the situation, it is planned to install an electric compressor and apply the transmission brake to the razdatka as the main one, and consider pneumatics a backup option. Although, in principle, engine braking on an all-terrain vehicle with a given mass also works well. Cooling works properly when accelerating to maximum speed, the oil in the automatic transmission does not heat up.

Then the author set about mounting the roof and sides of the cabin, 8mm plywood and 1mm profiled sheet, connected with exhaust rivets using sealant.

All-terrain vehicle sheathing works:

Testing the machine with the skin fitted:

Then the author purchased a new heart for Helmut:

Motor FD-42 Nisan diesel, 4 cylinders, 125 l / s at 3200 rpm, cr. moment 30.5 kg * m. Assembled with a manual gearbox.

Accordingly, the process of replacing the engine and gearbox began:

The engine has two belts per generator and air conditioning. In this regard, the compressor had to install the outlet flange of the box, the decision is justified by the fact that there is not enough space on the engine itself.

Gur and fuel drive drives are made through gear mechanism.

Instead of glow plugs, the engine has a nichrome frame design directly in the intake manifold.

Unlike the previously installed engine, this one does not need power after the factory. Therefore, it has no fans, and cooling is realized through a viscous coupling system.

One of the few modernizations of this design of the gearbox and engine bundle was to extend the wings, since the standard one, unfortunately, is not designed for a length of 4 meters.

The final stages of work with the all-terrain vehicle were the installation of heating. Heating in the winter period of operation will be carried out thanks to Webast stoves, which the author installed two at once. It is also necessary to replace the electronics for the winch, since the motor does not have a starter for 12 volts. A Webast stove does not allow you to install a conventional switch 12-24v, for fire safety purposes.

Here are some photos of mounting the engine design on an all-terrain vehicle frame:

In this photo the work of the suspension is clearly visible:

Photos of the finished off-road vehicle:

The author of this all-terrain vehicle: Alexander from Ust-Ilimsk, with the nickname "Stakanych".