Igor Korbut started doing this all-terrain vehicle many years ago. The basis of the machine was the legendary Gas-66. In the first place for the author was the reliability of the machine, so in construction he kept to one principle: fewer nodes - less damage.

The main components of the all-terrain vehicle:

1) The frame based on Gas-66 modernized and extended by 1500.

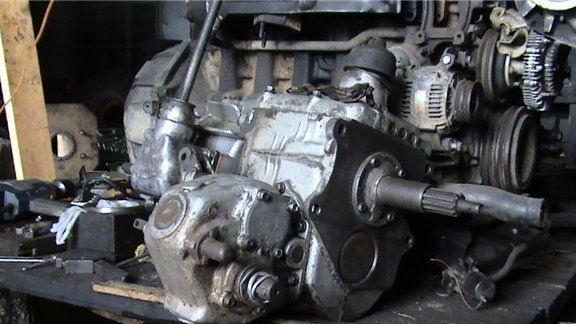

2) The gearbox, as well as the transfer case, were borrowed from the ZIL-157

3) Internal combustion engine TOYOTA 1HZ (4,2), aspirated, with a capacity of 136 l / s.

4) Wheels K-700, the entire tread on them was cut off, and the wheels are completely digested.

5) One of the unusual parts of an all-terrain vehicle is its skin and bodywork. So, for example, the hood is made from the fuselage of the AN-2 aircraft, and the kung machine is also made from it.

Now we will consider the stages of assembly of the all-terrain vehicle, as well as discuss the weak and strong points of the car.

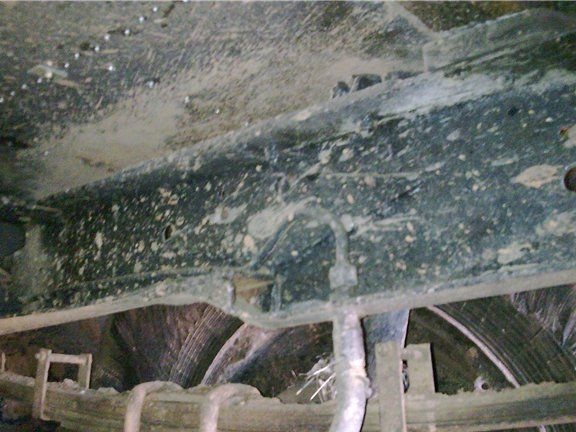

To begin with, the author decided to proceed with the refinement of the gas-66 frame for the new needs of the all-terrain vehicle:

During construction, the frame had to be done several times. Initially, it was lengthened by instructing the rear part from another L-90 cm frame. Further, a vulnerability of a similar design was discovered, the mid-axle universal joint worked at a large angle, and this, in turn, often damaged the crosses and the issue of replacing the ZMZ engine with a diesel engine became urgent 1HZ inline gear, but it is longer. And in order to solve these issues at once, the author cut the frame between the engine and the razdatka and pointed pieces from the same L-frame - 60 cm. As a result, the transfer case was shifted forward, and this shift made it possible to level the gimbal angle to its normal mode of operation.

All joints were boiled manually. A rhombus was cut from the same L -30 cm frame. It was superimposed on the joint and boiled, a longitudinal seam.

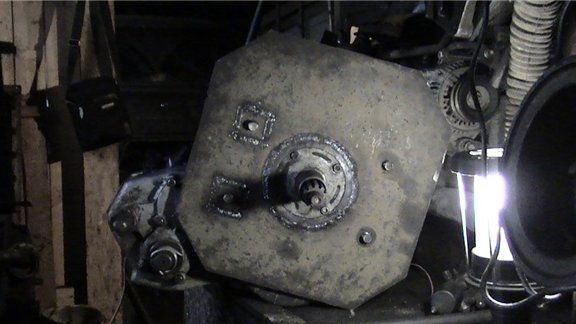

The fixture of the transfer case is native, it was taken from the ZiL-157 frame, but it fits the frame 66 in size. Holes were drilled, bolts with a landing with an inlet were machined, which the author simply hammered and tightened with two nuts for reliability.

The intermediate support "pig" and ZIL - 157.

The dimensions of the frame after such frauds turned out to be quite large.

1200 mm from the front shank to the distributor shank, 680 mm from the distributor to the middle axle shank, 2390 mm from the front shank to the middle axle shank.

And in this photo you can see the installed cylinder from the Urals:

Then the author proceeded to install the distributor, which was taken from a German combine:

The connection of the parts took place in a similar way: the spline was cut off from the combine shaft and the crosspiece from the GAZ-66 cardan, and then simply welded together.

The next step, the author began to install the steering gear.

here the first problem arose: the bracket to which the power cylinder is attached to the gas-66 is fixed to the gearbox with three bolts, and the Ural cylinder loosens them.

Therefore, two more brackets for gas-66 were taken, docked in a circle and scalded, and the author welded an ear under his finger from the Urals.

Then, holes for the cone were drilled in the bracket:

On the bolts dressed crackers taken from the steering bipod 66:

The next step, the author decided to start preparing shoes for his all-terrain vehicle.

I had to tinker with the disks, the components; the disk from the GAZ-51 and K-700 was inserted one into the other, since the disk from the gas-51 shoulder rests on the stiffener of the K-700 disk. Next, the alignment and welding of these two discs into one was carried out, if the weight is not critical, then you can leave it that way. However, the author decided to digest. To do this, he marked equal parts along the perimeter of the disk and staggered the pieces of metal from the different sides of the grinder, cut from the connection with the GAZ disk to the landing K-700. A stencil of a cut piece was cut out of cardboard. And from a barrel of 200 liters is already cut out on a stencil. Then the resulting metal fragment is inserted into the disc and scalded. For aesthetics, the seams are ground. Thanks to such manipulations by the author, the weight of the disk is reduced by half from what it was after the initial welding of the two disks, gas-51 and k-700.

Here are photos of the wheels already mounted on the machine:

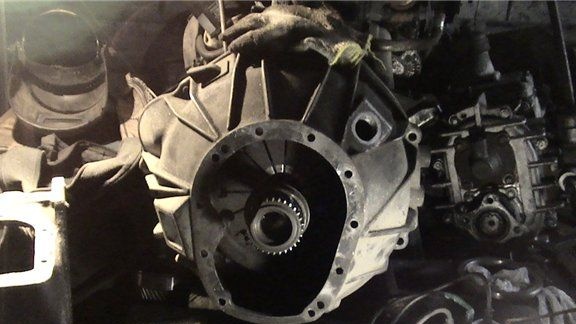

Now consider the power unit of an all-terrain vehicle:

The engine from the GAZ-53 was originally installed, but undoubtedly a diesel engine is needed for a heavy all-terrain vehicle. Diesel gives the thrust needed by such a machine, tangible fuel savings (both in price and in the amount spent to cover the distance), but there are certainly minus diesel engines - this is their considerable weight. And the weight of the engine TOYOTA 1HZ (4,2) is considerable.

Engine characteristics: V-4.2 135 l / s., With this unit, the consumption on the road is about 18 liters, in rough terrain about 35 liters, the engine is still lighter than the D-245. There is no electronics in it, the control of glow plugs is installed from the tractor, the diesel fuel is standard, the filters are from KAMAZ. A pre-heater from 66 was also installed. All axles were used standard from 66, no additional gearboxes, width 2990, 66-2525, turning radius despite this length is quite acceptable.

After installing the engine, the author proceeded to test the car, below you can see the video where the all-terrain vehicle is still without casing, but already on the go.

Construction Test Video:

Tests showed the car on the good side, so the author proceeded to install the cab and frame under the kung on an all-terrain vehicle. The photos below show parts on the cab and corners on the frame:

And in these photos the process of making kung is captured:

Then the author proceeded to the interior decoration of the kung:

This is how the vestibule looks:

The author filled the space between the frames with mounting foam:

One cylinder used.

Then it was decided to proceed with the installation of fuel tanks:

Installation of floor and heating under it:

In the photos below you can see the finished machine, as well as evaluate the capacity of the kung:

For heating in the winter period of operation of the all-terrain vehicle, a stove was installed:

As you can see, this stove not only warms, but also serve for cooking on long fishing / hunting trips:

The blower has an adjustable traction, so you can even block it at night.

The rear door design is quite interesting:

Thanks to this approach, the ability to load in a kung, for example, an author's snowmobile, is improved.

Photos of the off-road vehicle:

The author of this all-terrain vehicle Igor Korbut from the village of Leshukonskoye, Arkhangelsk region.