Tracked all-terrain vehicle "Earthling". The creator of "Alekseevich52" under this nickname is registered on the forum "" Andrei Alekseevich Raevsky from Nizhny Novgorod.

The small caterpillar all-terrain vehicle on a wheeled-caterpillar track turned out to be very good and solid, this was even shown on the plot in regional television.

It all started with the preparation and collection of small parts and assemblies. The most dreary part of the job is the manufacture of the track.

With this, our designer began car making.

The tracks are made of 50x25 mm pipe.

The emphasis or guide tracks are made of round timber with a diameter of 10 mm, a height of 80 mm.

Lugs made of reinforcement.

The ends of the tracks are welded tight so that dirt and water do not get inside.

Holes are drilled to secure the trucks to the conveyor belt.

So the caterpillar will go on wheels.

Everything is welded on tracks and lugs and guides.

The tracks are painted.

The tape is cut for the tracks in width and length.

Track assembly tool.

Caterpillars are assembled, the sizes along the tops of the fangs are 215 mm, along the bottoms-165 mm.

Truck from a pipe 50 mm wide, gap between tracks 80 mm.

8 mm fittings to prevent the drive wheel from turning.

Preparing the engine for installation.

Shortened axle shafts.

A bridge with cropped stockings.

The axis from the seeder with the clutch for the manufacture of interlocks.

Locking from one clutch, and drive-chain, the opening mechanism has not yet been invented.

The frame is welded and clad on caterpillar wheels.

Flanges are cut from the same donor bridge and come in handy.

The engine took its place.

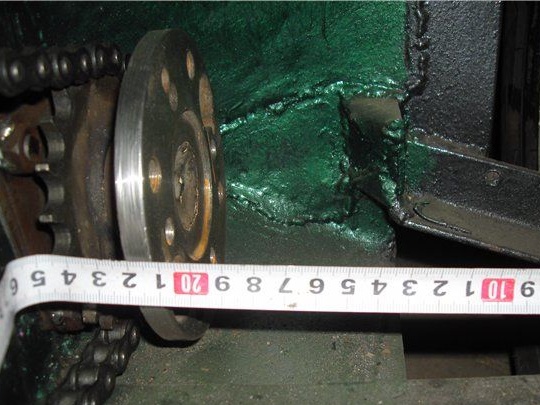

This is a scraper, to clean the drive wheel from snow and dirt.

Running-in suspension work, while without a caterpillar.

The location of the wheels on the frame in size.

Checking the tension of the tracks by rolling on the logs is satisfactory.

The handout is located inside the boat.

Outboard bearing.

The bearing is welded into the housing with sealing.

Front axle drive out.

A cardan shaft will be fixed to the flange, which will rotate the front axle.

Middle levers of fastening of basic wheels.

Wheel axles are attached to the frame and shock absorbers are dressed.

Caterpillars are dressed.

The suspension works great. Video

Oil seals for the front axle.

Front axle drive through the hull assembled.

Installing the driveshaft on the front axle.

Shafts for assembling the lock assembly.

Lock collected.

Drive wheel drive through a chain drive.

Front axle caliper mount.

Brake pads are assembled on a support.

The front axle is ready for installation.

The bottom of the all-terrain vehicle is primed and ready for assembly.

Installed propeller shaft to the front axle.

Front axle assembly.

Boat on wheels, further engine installation, etc.

Made fork for clutch release.

The gear lever is installed in horizontal position.

Gear shift test. video

Test operation of the lock and brake release lever. video

The distance between the flange and the caliper.

A universal joint shaft from UAZ was manufactured and installed.

Test drive without tracks. Video

The first exit. video.

The caterpillar is assembled from a conveyor belt with a thickness of 10 mm, 4 layers of cord, lapped under the lap for three tracks.

Snow fell and adapted the auto-make for clearing snow.

All terrain vehicle ready.

Neighbor also shot about the all-terrain vehicle.

Andrei Alekseevich success in the all-terrain building business.