This all-terrain vehicle It was named unusually chiffonier due to the body structure, and its unusual appearance.

When creating an all-terrain vehicle, the author was guided by the idea that the chassis on the all-terrain vehicle should be simple, minimum maintenance, maximum reliability, and simplicity should be the same in the extraction of all components for repair.

As a result, the choice fell on gas-66.

The all-terrain vehicle was assembled mainly from what was at hand, and parts of other collected all-terrain vehicles of the author were also used.

1) The chassis was shortened from the Gas-66

2) Used half a penny body

3) Initially, the author was going to use the VAZ 2106 engine, but then a diesel engine was found model 19-88 IFA.

4) disc brakes.

5) a donor of tires - KRAZ-bast.

Consider the stages of planning and building an all-terrain vehicle.

Regarding the work on the chassis, the author shifted the rear axle by 30, and the front axle by 60 centimeters. For this, the spring brackets were dismantled and secured elsewhere with bolts. The frame is shortened by 80 centimeters and 60 kg, this relief is more done due to the engine. Disc brakes are used, because weight matters for an all-terrain vehicle, the all-terrain vehicle spends half of its life knee-deep in mud, so native brakes are removed and discs are mounted on the axle shaft.

The size of the all-terrain vehicle on patency does not have a significant role. (except for the option of driving on a colony)

After these not strong modifications of the chassis, the author proceeded to shoe the all-terrain vehicle.

For starters, rubber was prepared for the all-terrain vehicle:

One outer wire band was removed, but the inner one remains.

It also removes 2 full layers of cord and incomplete ones in the assembly around the bandage.

And then the tread is cut, leaving an additional 2 layers under it.

As a result, we got a tire weighing over 30 kilograms, on the side of 6 layers on a running 8 (margin for wear and puncture), the dimensions were 1300-500.

The rim consists of 2 of gas, is collected on the hub.

Below are photos of the mounting bolt, as well as the method of mounting the tire to the disks:

Photos of assembled and finished wheels:

Here you can see the welded disc:

The disk is assembled at the farms, nuts are welded to the internal disk,

The remaining 4 holes are mounted on the disk, respectively, on the disk 2 studs are removed.

Given the rotation of the wheel, the distance from the axle studs to the springs will be slightly less in the region of 42 centimeters.

Distance from disc to tire edge 28.5 centimeters:

There is 12 cm left to turn the wheel, this is not much.however, it’s difficult to find a lot of space in the forest, and there is also a reverse gear. Due to this design of the discs, the track will be less, it’s easier to get into the track of already killed our roads.

Such an engine was installed on the machine:

This is a diesel engine from Multikara 25, model 19-88 IFA, 2 liter atmospheric, power 45 hp, 3000 rpm, weight 230 kg, torque according to the Internet 21.

Consider the work on the transfer case.

This is how the transfer case is installed:

View from below:

This design has undergone many alterations.

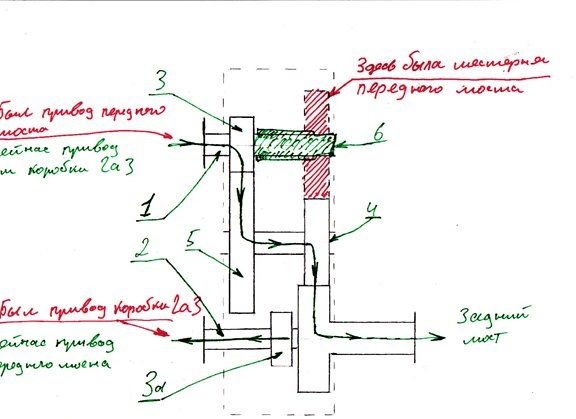

the front axle gear with the shaft was removed, and the primary shaft (this can be seen in the figure below) with extension 6 was installed in their place so that this part would fit on the native bearings and gear 3 (the one that includes the direct and low gear in the transfer case), then . the shaft with its gears 4 and 5 (on the shaft, the gears from movements are held by the sleeve and washers), then the rotation of the rear axle in the direction of the arrow. The front axle is connected by a gear 3a (which previously included a lower one) so that gears 5 and 3a do not meet on the rod there is a tube travel stop.

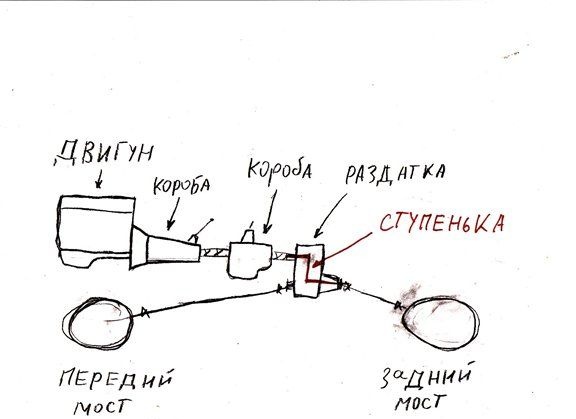

All this was necessary to make it easier for the engine to carry weight, therefore, in addition to the axle gearbox, the transmission also needs to lower 1k2, in this case both boxes are used to fully load the axles. And also due to the fact that the engine with the gearbox is highly placed, it was necessary to make a step in the transmission to transmit rotation to the rear axle, as can be seen in the figures below:

It is more convenient to lower the gear in the transfer case, otherwise the box from Gaza will work exclusively in 3rd gear. The driver has at hand two box levers and one axle activation. And also the transmission with this approach is long, and the all-terrain vehicle is shortened, so it’s more convenient to transfer rotation to the rear axle as a step. At the gas-66 transfer case, the reduced gear is switched on on 2 bridges, and there is another inconvenience - mobile gears, and such defects inevitably occur.

Therefore, it was done this way: front axle engagement gear

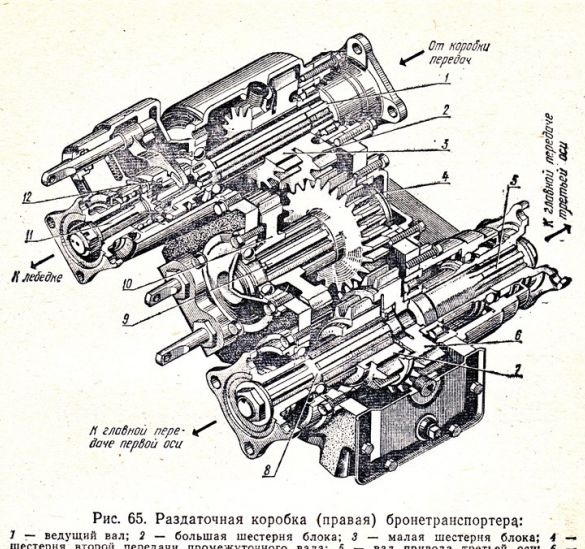

That is, the armored personnel carrier design was borrowed from the part:

Works with the driveshaft:

The cardans were shortened manually, with the help of a grinder, a pipe was cut in the lathe, a welding seam was removed from another piece of pipe in the lathe and the fork was removed. Further, the author collected everything, set the forks correctly and brewed.

The coupling between the boxes from the Niva, only the cross is enclosed in two identical three beam parts. I had to redo the rear support. The native Zhiguli is too soft, sags and gives vibrations, and the coupling is short, so there were big distortions.

The author shortened the input shaft of the gas-66 box, installed a second bearing, 5 rollers from the bearing transmit rotation.

And here you can see the rear axle drive:

Front brake:

As for the disadvantages of the all-terrain vehicle.

When braking for one revolution of the disk, the rotation is braked while the bridge bends forward, and when the disk goes back the bridge. In this case, the transfer case rotates evenly, and the rear drive shaft from the rear axle at each revolution - the bite of the bridge is braked and accelerated.

The bridge with spring suspension has no longitudinal stabilization. If the springs of a normal car are strong enough to support the weight and the bridge from pecks, then homemade all wrong. For other cars, say Lada rear suspension is longitudinally stabilized.

Although the problem may also be in poor-quality disc brakes or design flaws by the author.

In any case, the author decided that this is not very radical for the alteration of the entire suspension structure. But he admitted that the factory brakes from the gas-66 would have looked better in this regard.

Another problem that arose after assembly. Laptevy rubber reached the body in a tight earlier than before the spring, so the author simply limited the rotation of the wheels, using for this purpose the welding of nuts on the thrust restrictive bolts that stand on the knuckles. Thanks to such actions, the rotation angle has become slightly smaller, although in practice this is not very noticeable. Bridges are standard. The full width of the all-terrain vehicle turned out to be three meters; the width of the bridge was almost two meters along the hairpins, that is, the central plate in the disk was boiled almost from the edge of a regular cannon.

Photos of the finished all-terrain vehicle with its author:

Video with an all-terrain vehicle:

The author of the all-terrain vehicle "Viktor D" is the village of Mirny, Yakutia.