The tank was built to participate in the celebration of the 70th anniversary of Victory in the Great Patriotic War.

"Tank crew" - I think this is the builders of the tank.

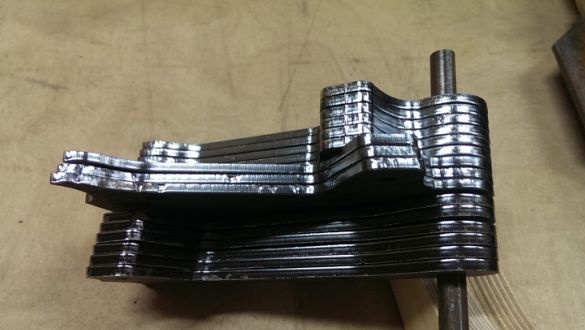

The most difficult in the construction of tanks is the caterpillar. Therefore it was begun construction from her. It should be noted that not a single living true instance could be found along the way.

All tanks 959 pcs. were released before the war. During the war, the tower was mainly used as a bunker. Therefore, the caterpillar is restored from pre-war video chronicles.

The model uses modern materials. Track model. PND sheet of 20 mm and sheet metal of 4 mm.

PND sheet milling on a CNC machine.

Assembly.

The caterpillar is going.

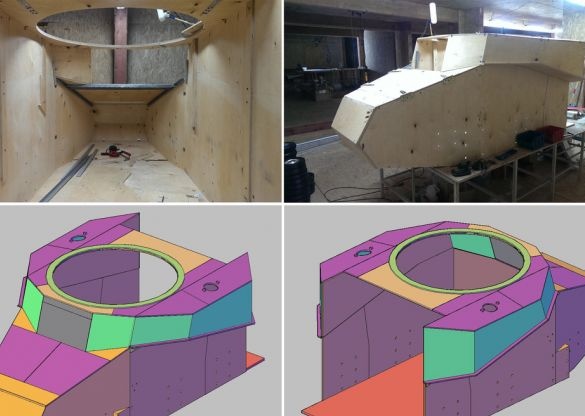

The plywood model of the transmission gives an understanding of what and how it works. Track Roller.

At the Vadim Zadorozhniy Museum, external measurements of the tank were carried out and a plywood three-dimensional model of the tank was built.

Welded the body from the corner and profiles.

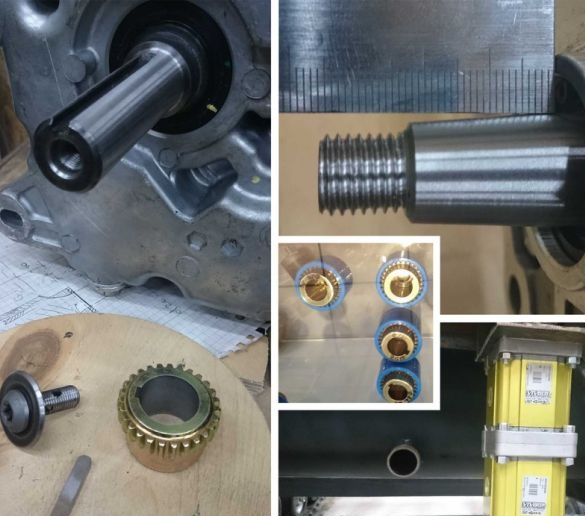

Wheels supporting 150 mm in diameter. Support wheels with a diameter of 250 mm. Rolling axis of the support wheels. The axis of the tension wheel. A tension wheel with a diameter of 650 mm hangs cantilever on a movable lever.

The suspension axle of the tension wheel is 36 mm from the bar, and the parts are cut from metal by plasma cutting. One half of the axis. The axis of the wheel tension on the tank body.

The drive sprocket is made of metal.

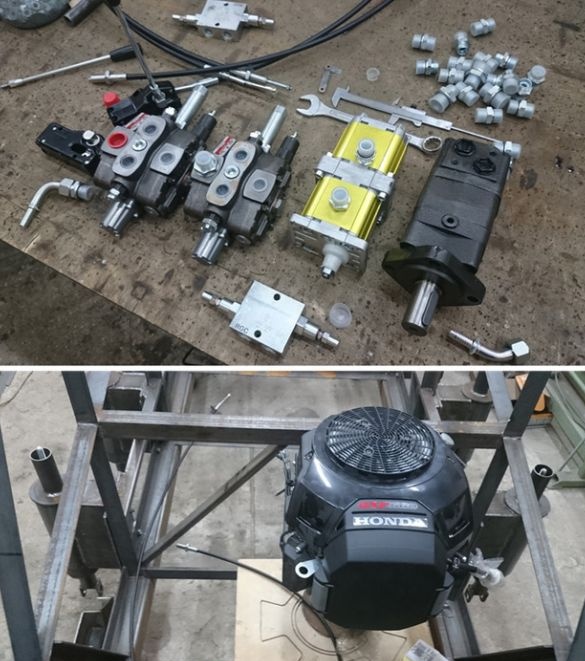

It was decided to put a hydraulic actuator to reduce the weight of the tank. Hydroallocators and hydraulic pump. The original version of the engine. Honda GXV 660 21 KM 48 Nm.

The main element of the suspension is shock absorbers. According to calculations, shock absorbers from the Oka car came up. Spring loaded track roller. Shock absorber housing. This will attach the shock absorber body to the tank body.

Total, according to approximate estimates for the hydraulic drive spent:

Two-section gear hydraulic pump (tandem) Vivolo pump, 2 sections of 16 cm3-25-30 thousand rubles each.

Three-section hydrodistributor (forward-neutral-backward) 2x25-30 thousand rubles.

Hydromotor MS315 Motors (Danfoss analog) 2x 25-30 thousand rubles.

Oil tank -25 thousand rubles.

Oil 200 liters-14 thousand rubles.

Small things: fittings, adapters, high pressure hoses, filters, valves, fittings ...

The connection of the engine and the hydraulic pump. The motor shaft is not in the metric system. The pump shaft is conical. Adapter sleeve. Clutch on motor shaft. The pump is connected to the engine.

The low side of the pipelines is welded from polypropylene pipes. A generator drive pulley was installed on the engine shaft.The ball valve was soldered to shut off the oil supply from the hydraulic tank and not drain the oil in case of repair.

Suspension system for support rollers. Suspension system calculations. Assembly of supporting rollers. Assembly of supporting rollers.

The axis of the rollers. Running assembled.

Welded silencer from an old fire extinguisher. Installed a seat from the loader. Oil is poured into the hydraulic tank.

The first exit. video.

The run-in showed a low engine power and it was decided to replace the engine with a more powerful one.

New video engine.

It was decided to fix the pump drive coupling directly to the flywheel.

Hydraulic system. The engine on the frame.

Some of the original parts had to be cast from aluminum ourselves, so that it was similar to the original.

A chamotte muffle furnace wrapped in a nichrome spiral. Model.

Casting. Ready product.

The process of casting parts. video

Details obtained in the casting process.

Manufacture of other parts.

Armor on the tank was fastened with rivets. Sheets for armor were taken from HDPE with a thickness of 10 and 20 mm. It was necessary to produce 800 rivets.

Made it all on a milling machine. Rivets look like real

The most frightening part of the tank is the tower. The arrow rotates by force, so it should be light, so profiles are used and PND sheets instead of armor.

To make the hatch, it was necessary to make a mold. Made of multilayer MDF by milling.

Armor plating process.

Making a gun. video

Everything is removed before painting.

Running in.

Painting the model of the tank MS-1 (T-18). video

Victory shot of the tank.

Mission accomplished.

But the point was not put on the construction of the tank. The plans also include an increase in engine power, the installation of headlights, signal, mudguards, a movable machine gun, a firing gun and marking, and further participation in reconstruction of battles.

.

Good luck to car mechanics.