Alexander Yudin on the forum site is registered under the nickname "aleks727". Building an all-terrain vehicle and improving it later

It takes a lot of time to master. The initial idea of the author was very modest and he just wanted to go fishing in the summer in his all-terrain vehicle.

Video about "Luntika".

The performance characteristics future all-terrain vehicle.

The engine from the VAZ, together with the gearbox from the VAZ-2106, is 4-speed.

The lowering reducer - reducer from the starting engine of the T-130 tractor.

The differential rotation.

Drum brakes from the classics.

Support wheels from "Niva" R16 /

Wheel hubs - front from the classics.

The caterpillar is assembled on a conveyor belt.

Track tracks.

Press for the manufacture of trucks.

Front hub from the classics.

Modified hub for an all-terrain vehicle.

An attempt to build a balancer from the spring "Zila-Goby".

That’s what the Luntik’s chassis will look like.

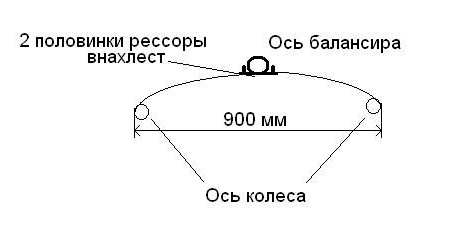

The balancer mounting scheme. Spring thickness 10 mm, between wheels 900 mm.

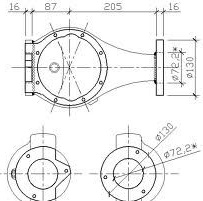

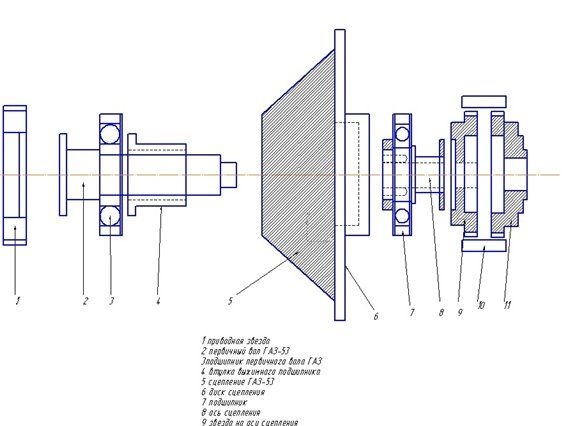

Alteration scheme of the rear axle "Niva" for use as a driving axle of an all-terrain vehicle.

The main gear housing of the gearbox of the bridge is sawn.

Bearing installation.

Welded plates to the gear housing.

Bearing flanges are welded to the plates, the bearings are still native to Niva, cooked by the Cyclone-200 semiautomatic device.

The brakes will be disc on the axles. Half shafts complete with gearbox.

The first track is welded for sampling.

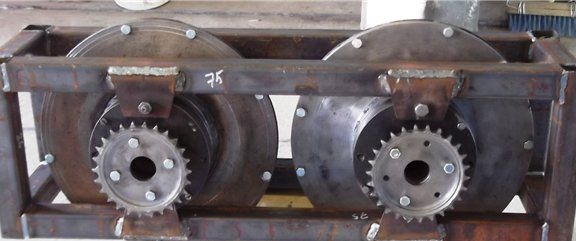

A new balancer using a hub from the VAZ-2101 is welded.

Production of teeth for the drive sprocket, the first option.

Making the teeth of a star from a set of conveyor belts. The wheel is wrapped with a conveyor belt 10 mm thick. 8 teeth per star, tooth width 170 mm, secured with three M12 bolts, track pitch 85 mm.

The base of the leading star.

The star is assembled.

Ready piece of caterpillar.

Teeth for the second drive sprocket.

Device for drilling holes in the conveyor belt.

Blanks for trucks.

Track tracks.

Welding trucks semi-automatically in an argon environment.

The manufacture of limiters.

The ends are bent.

Fitting a caterpillar onto a star.

Track on the idler.

The support wheels on the balancer of channel number 10 (shelves-8 mm, bottom-5 mm). The length is 1020 mm, the distance between the centers of the wheels is 900 mm. Wheels R16, the axis of the balancer is the front hub from the VAZ-2101.

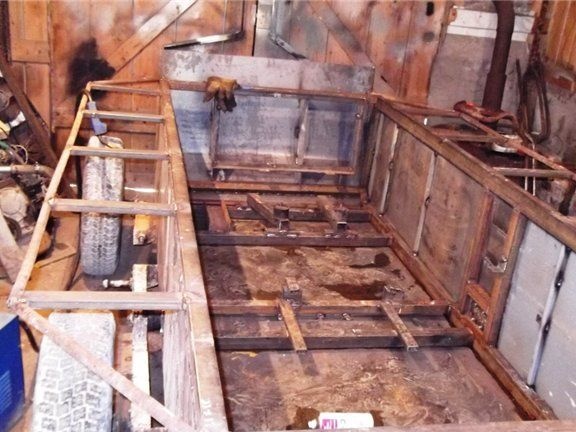

The hull of the boat is welded from the profile.

Track tension mechanism.

A tension wheel is installed and a caterpillar is dressed.

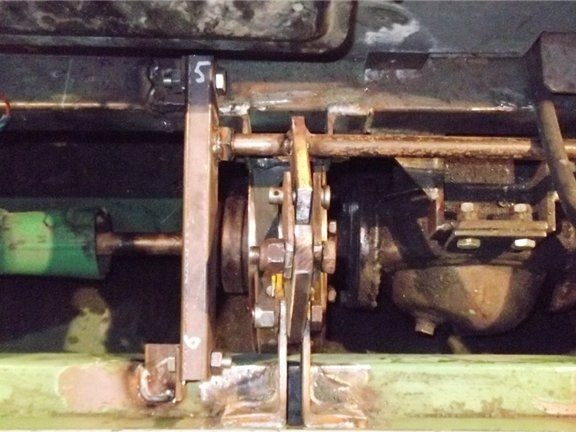

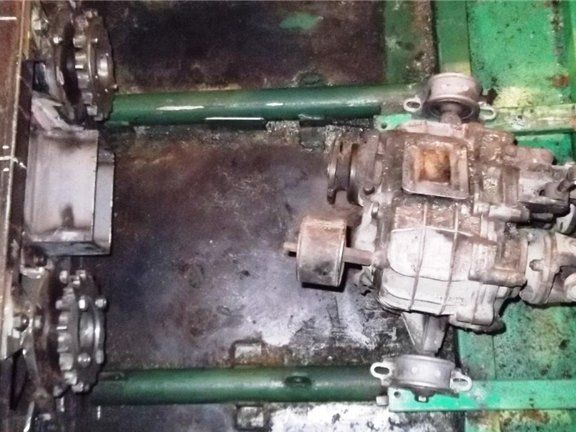

An estimate for installing the engine and handouts from the "Niva", the universal joint shaft and the drive axle.

Gearbox mount and handouts.

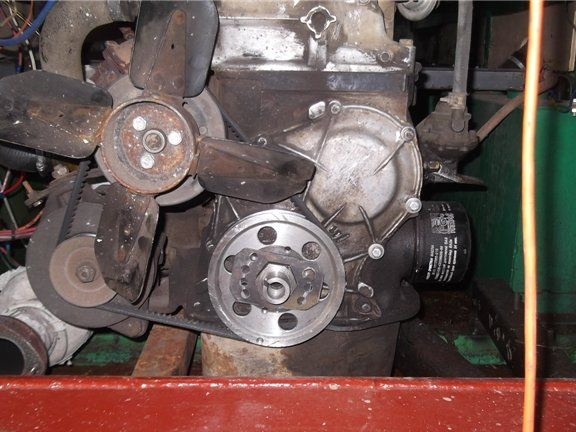

The engine is installed and running.

The drive axle is mounted and brakes are fixed to the caliper.

Half shafts and grenades are dressed from the Niva driving bridge.

New radiator from the VAZ-21213.

In the video, the running track. video

The first test drive. video.

The second exit. video.

After running-in, the chassis was removed and the welding of the boat and reinforcement of the entire hull began. The bottom is sheathed with a metal sheet 2 mm thick. The size of the boat was about

1170х610х2750 mm, displacement - 1.9 tons.

Checking the tightness of the boat on the lake. Board height - 600 mm, drawdown 120 mm under the weight of 4 men.

The sides are welded.

Fitting the cab.

Adapter flanges from the axle of the classic to the Niva wheels.

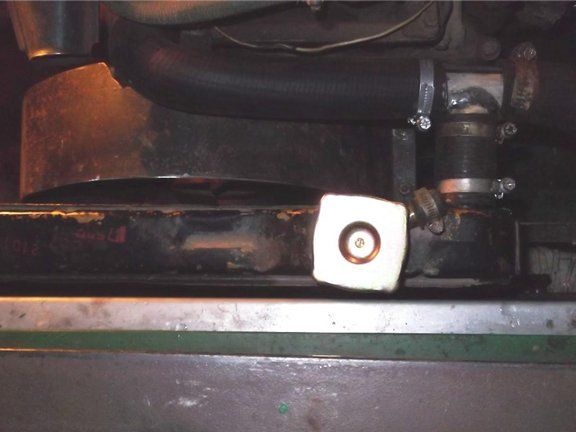

A fuel tank of 40 liters was installed and vacuum amplifiers were installed.

All equipment is installed.

All terrain vehicle swam. video

Brake band for alteration of the brake system.

The system is taken from the T-130 tractor and adapted to the all-terrain vehicle.

Management has become easy.

The navigator speed is 42 km per hour.

Drove to the dirt. video

Set the doors to the cab.

Luntik is waiting for good snow.

Weaknesses were revealed, a corner was torn off, and welded.

Pokatushki in the snow. video

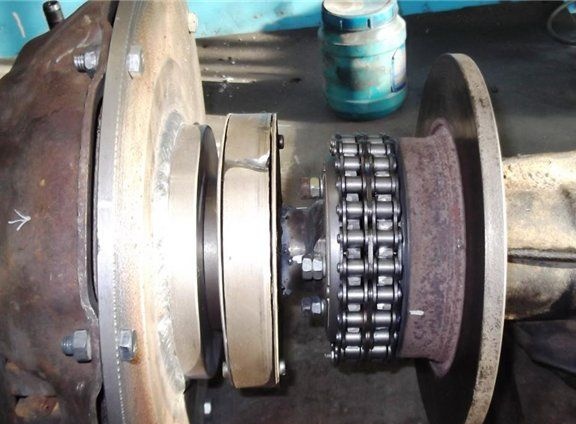

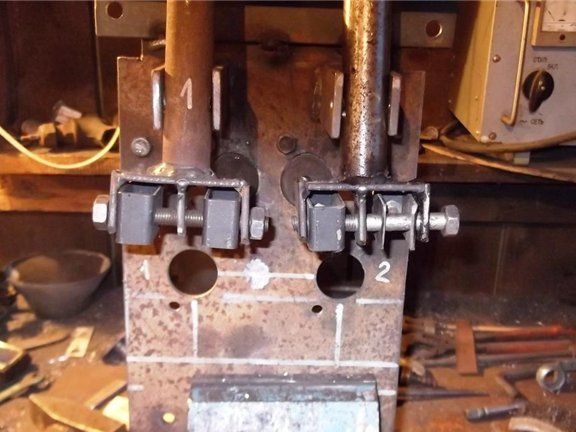

It was decided to redo the turn on final drives with a clutch from GAZ-53. Clutch disc from GAZ-53.

He machined a flywheel from a metal 10 mm thick.

Clutch flywheel.

Basket from the clutch.

Adapter under the shank from the VAZ.

Shaft bearing.

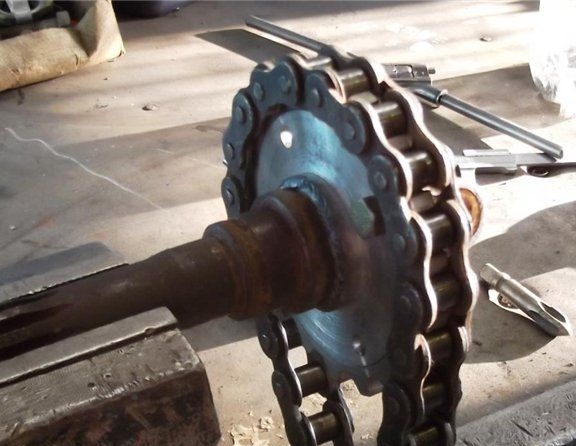

The mechanism is assembled.

Releaser bearing seated on input shaft.

The clutch is assembled. video

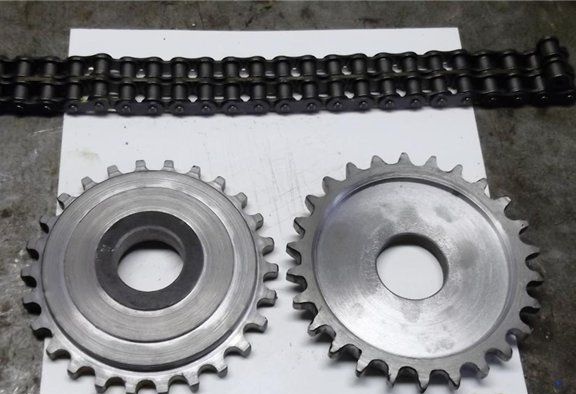

Double row chain gear for connecting to final drive.

I glued a sheet with a drawing of a wheel on a blank for a star, screwed it up, drilled it, processed it on a lathe.

Coolant supply system for a drilling machine.

He used hex bolts to connect the sprockets.

The connection of the final drive with the clutch.

Flanges for the second pair.

The differential is locked.

One stocking of the bridge is cut off.

It remains to brew bridges.

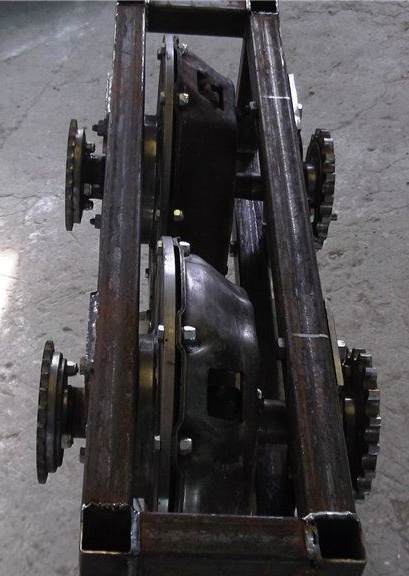

Approximate layout of the bridge with clutches.

Another star is ready.

Removable sprockets, star pitch 25.4.

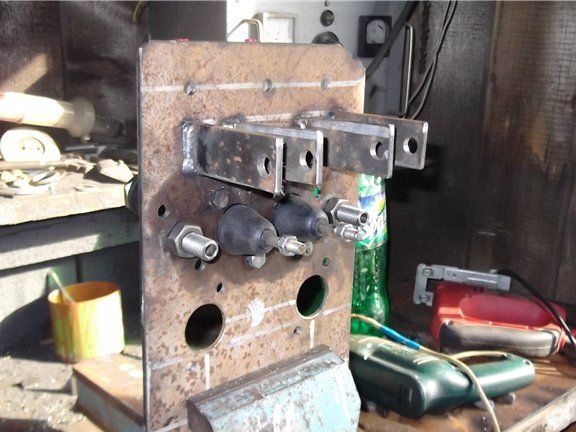

One clutch is fully assembled.

Clutch assembly diagram.

The result is a complete friction clutch.

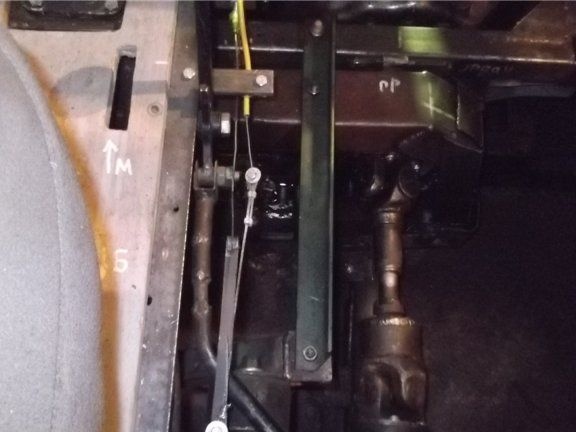

Clutch control will be cable.

Alteration of the chassis of the "Luntik". The diameter of the roller is 120 mm, the wheels are 300 mm, the width is 170 mm.

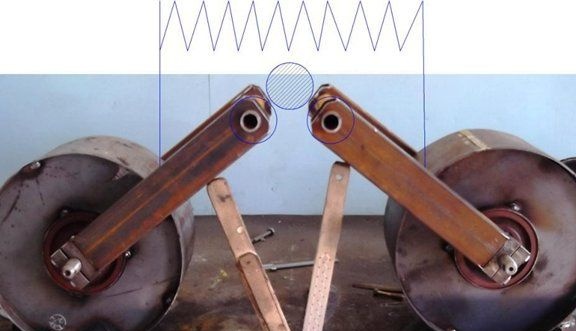

Pendant "French scissors".

The spring will be here.

This will look like the carriage of the chassis on the Luntik.

An old bridge is cut from the hull.

The whole turning mechanism climbed in instead of the old bridge.

Clutch installed.

Cardan shaft output in the middle.

How to install a razdatka ?.

There is a process of deep modernization.

Clutch cable control replaced by hydraulic.

Hydraulic cylinders are installed separately on the brakes and on the clutch.

Build process in progress.

Redid the gas tank.

Redid the fan under the left rotation.

Installed brake calipers.

Clutch operation. video

First departure after modernization. video.

Included additional air intakes.

Additional fans are installed to blow the entire boat.

An additional radiator from the VAZ-2101 is installed.

Cut the sidewall to install the radiator.

I installed the radiator in a new place.

The view from the outside.

Inside view.

He made a strapping of radiators from plywood 10 mm thick.

A puck worth 5 cents.

Sheathed with plywood.

Installed power steering pump from ZIL-130.

Knife for cleaning snow.

The knife is lifted using a drive from an electric motor.

The operation of the gearbox to raise the knife.

Wet snow sticks to the lead star.

Assembly of brake hydraulic cylinders.

Descent of a caterpillar on a slope.

Such a slope.

The caterpillar is dressed. The last nut is tightened.

The gearshift lever is shortened and threaded. A nut with a welded tube is screwed onto the thread, and a bracket with a pipe from the side of the VAZ-2109 is inserted into the tube.

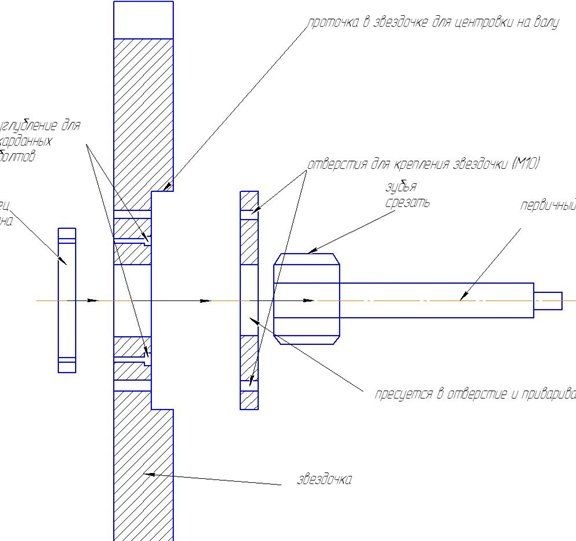

Drawing of fastening sprockets for chain transmission, input shaft of propeller shaft.

The scheme for raising the knife on the hydraulics is assembled, it remains to transfer to the all-terrain vehicle.

During snow cleaning, a wheel broke.

Redid the knife mount.

Snow cleaning with hydraulics. video.

The beginning of the third modernization of the Luntik.

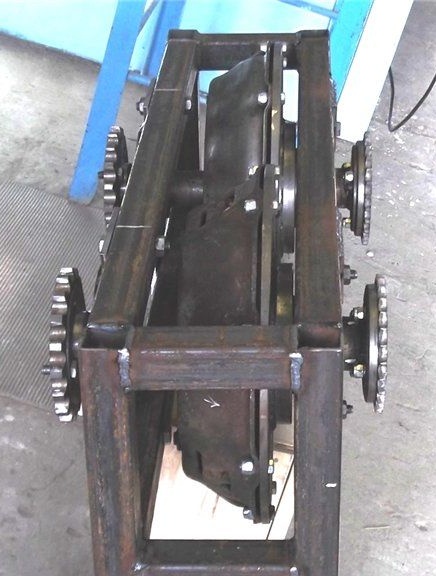

Undercarriage undercar.

Installing a second trolley. It remains to install the tension wheel and throw the track.

It remains to put the tensioner and supporting rollers.

The assembly of the chassis continues.

Driving test. video

A chain has been added to the springs to limit the suspension travel.

Routine inspection.

Installed new pulleys for the drive of the NSh-10 hydraulic pump.

Installed a shock absorber on the last rink.

The caterpillar has torn.

He pulled out the tracks and patched.

Inspection of the tape tracks.

One goose is collected and dressed on an all-terrain vehicle.

The second side is going.

The author of Luntik on the left is Alexander Yudin.

The next exit and caterpillar gathering followed by a breakdown of the axle shaft.

Limiters bent.

Guide stops restored.

Redid a knife for cleaning snow from a barrel of 200 liters, cut in half.

Installed hydraulics for the knife.

Redone manual gas.

Departure through the snow. video.

We wish success to all-terrain vehicle Alexander Yudin, because he is starting a new project.