In many household plots you can see the so-called summer shower. Its design is quite simple - a small container located on the building is filled with water. As it is exposed to sunlight, it heats up to the desired temperature. But it is not always convenient to wait a few hours until the water is at an acceptable temperature. Therefore, often this design is slightly modified by adding a solar collector to it.

Principle of operation

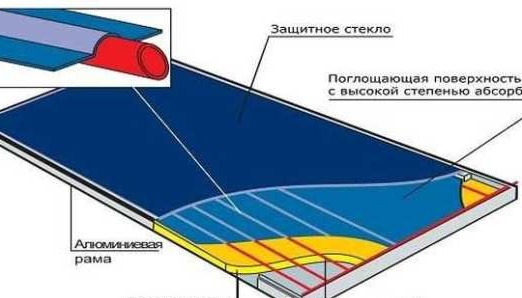

It is a panel, inside which is a network of pipelines. On the inside there is a heater (to reduce heat loss), and on the outside there is a protective glass. It also performs another function - it creates a greenhouse effect inside the collector. Under the influence of sunlight, the water in the tubes heats up, and the protective layers minimize energy loss.

For the manufacture of the device according to a similar scheme, special tools, significant financial costs and a large amount of work are needed. Therefore, "folk craftsmen" developed an alternative model from cellular polycarbonate. Its specificity is the use of cavities instead of copper tubes. If you properly ensure the flow of water into the cavity and its further intake for use, such a design can replace expensive factory models.

How to make a polycarbonate solar collector do it yourself and what will be required for this? Before you begin to develop a manufacturing plan, you should find out a number of important differences and limitations for this model of solar installation.

The minimum pressure of water. The connection of polycarbonate and PVC pipes will be carried out using hot-melt adhesive, which cannot provide the proper level of reliability. Therefore, the operation of the pumping station or connection to the central water supply system is excluded.

Such a collector is much lighter than factory models (their types and capabilities are described here), which makes it possible to install it directly on an outdoor shower or roof of a house.

Knowing these nuances, you can start manufacturing.

To perform the work, the following consumables will be required:

Polycarbonate sheets

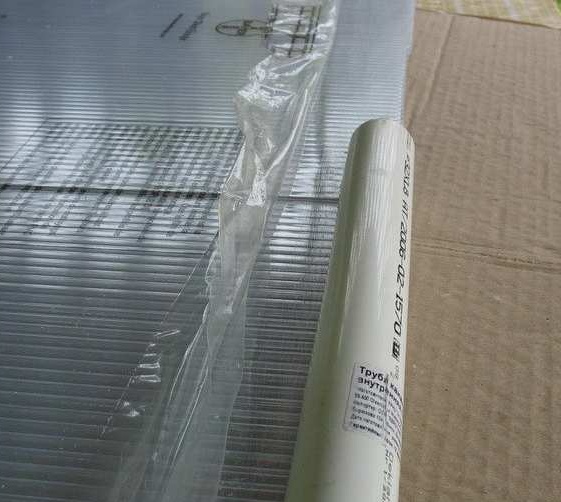

It is necessary to choose models with honeycombs, in which water will be heated. Standard sheet sizes are 12000 * 1000 mm. It is best to make a design with overall dimensions of 2000 * 1000. Those. For this, two blanks will be needed - in one of them water will be heated, and the second will serve as external protection.

The useful size of the collector will depend on the size of the cells. Optimal are sheets from 4 to 8 mm thick. For them, the liquid volume per 1 m² will be 35 and 80 liters, respectively. With the selected dimensions, its weight in the filled state will be optimal.

PVC pipes, flexible hoses and fittings

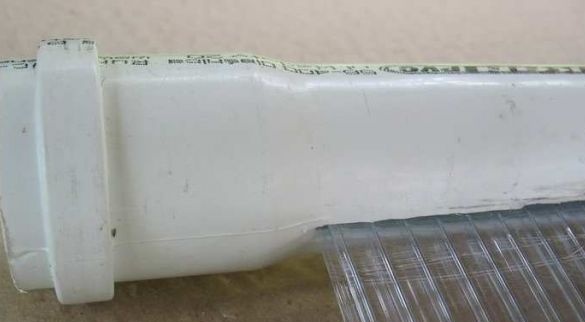

An optimal pipe is PVC (32 mm) with a threaded connection. Its length should be 2050 mm (50 mm for connection). Fittings and flexible hoses are required to connect the collector to the water supply and intake system.

Drywall Frame Profile and Styrofoam Sheets

Surface treatment is carried out with an angular grinding tool (grinder), the connection of individual elements is carried out using hot-melt adhesive.

Procedure

Before performing work, it is important to properly navigate the location of the cells. They should go horizontally, which will ensure uniform heating of the water. First you need to make longitudinal cuts in the pipes. To do this, they are fixed with clamps. It is necessary to ensure the most even cut lines, for which a special circular saw is used for a grinder with small teeth.

A polycarbonate sheet is inserted into the resulting cutouts, which will act as a solar collector. It is important to install the edge of the sheet in the pipe not to the stop - it should go into the internal cavity by a maximum of ¼ diameter.

Then, using a heat gun and plastic adhesive plates, the joint seams are sealed. It is recommended to perform this procedure in 2-3 stages with an interval of complete drying of the adhesive base.

It is absolutely necessary to carry out control tests of the collector before installing the protective frame. Using fittings and flexible hose, it connects to a storage tank with water, which should be filled to the maximum. The design is installed in an inclined position and the presence of leaks is checked. If they are missing, you can proceed to the next step.

For better heating, it is recommended that the surface of the sheet be painted black. To do this, you can use ordinary spray paint.

Frame assembly

As a material for the manufacture of the frame, galvanized profiles for drywall are used. They are selected in width, which should correspond to the total thickness of 2 sheets of polycarbonate and foam. Most often, products with dimensions 40 * 75 * 40 are used.

First, a thermal insulation layer of foam is laid, which is attached to the profile with screws. Then on top of it lies the collector and the protective sheet. For stiffness, it is recommended to install transverse rails.