Tracked all-terrain vehicle Termite T-3 Hydro was built in St. Petersburg. This is the sixth model, which was built by this group of all-terrain vehicles. On the forum site "" about the all-terrain vehicle writes

"KiraY". Hydraulically-driven crawler-mounted all-terrain vehicle and radio-controlled is used as a self-propelled unit for vertical drilling installation.

On the video, the moment of checking the hydraulics on tracked all-terrain vehicle "Termite T-3 Hydro".

In the machine park there are two drilling machines, one lathe, a small portal plasma cutting machine.

Keys, small things like everyone else-welding, grinder, etc.

The performance characteristics.

Engine from a VAZ-21083, carburetor, 1.5 cubic meters.

The cornering system is differential, but later on with a rework on side clutches.

Suspension suspension system on independent balancers.

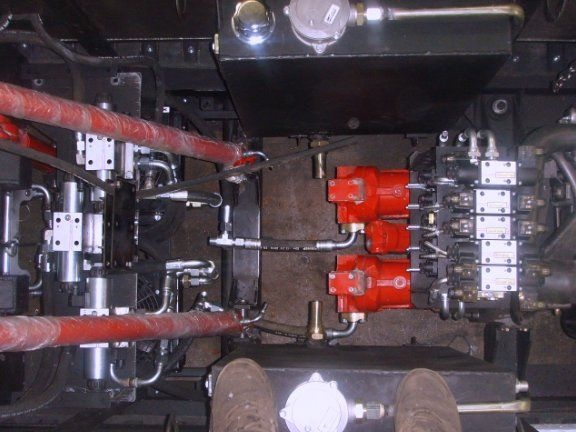

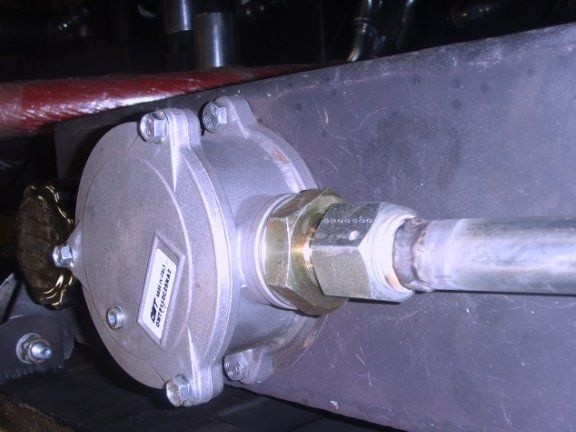

The drive is hydraulic, volumetric, gerotor, high-torque hydraulic motor.

Weight is 1500 kg.

Payload 3000 kg.

Ground clearance is 350 mm.

Length is 3000 mm, width is 2100 mm, height is 1200 mm.

The minimum speed is 7 km \ hour, and the maximum is 15 km \ hour.

Radio remote control up to 40 meters.

Running in the mountains of the Caucasus.

The assembly of the suspension arm.

The suspension balance is assembled and sanded.

The balancer is assembled on bearings. Four wheels per balancer. The wheel can withstand 500 kg. There is a 24 wheel on the chassis.

Wheels on bearings with an aluminum base.

Final drive gearbox.

Limiter.

The frame is welded.

Cups for assembling shock absorbers.

Shock absorber assembly from the classics.

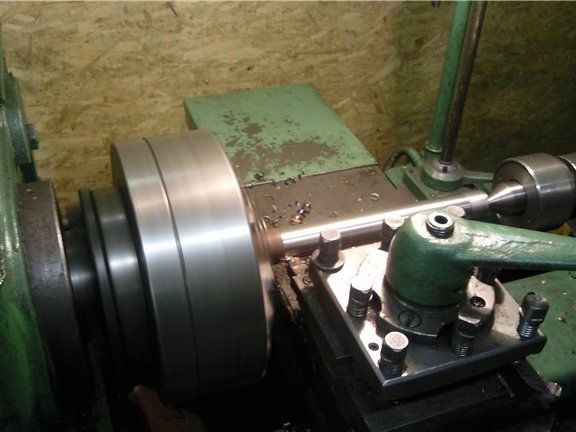

Mounted axes are cut and machined.

Work on a lathe.

The decor panel amplifiers with the company name are cut.

The suspension unit is assembled on bearings.

Track rollers on balancers assembled.

Amplifier frames are ready.

Amplifier frames figured to the frame.

Balancers with rollers hung from the frame.

Engraving mill on steel sheets.

The skew system is assembled.

Housing has started.

Moments of the casing.

Wings are welded to the main body.

The process of manufacturing body metal.

Production of cases of boxes for small things.

Two hydraulic oil tanks were made.

Top view on all-terrain vehicle.

All sorts of axles are ground for an all-terrain vehicle.

Details are disassembled before painting.

After painting.

Assembling painted parts into components and assemblies.

Primer frame on all sides.

The frame is painted and assembly begins.

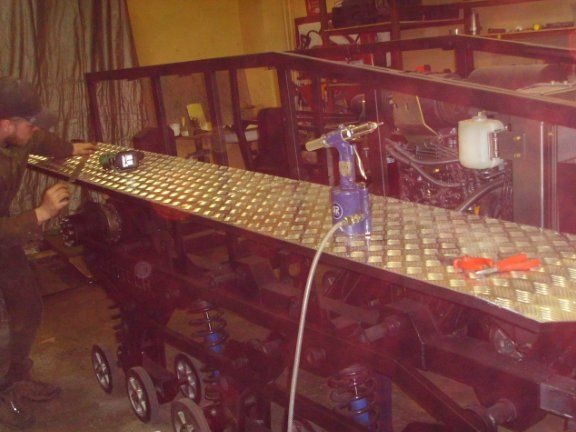

The chassis is hung on the frame body.

The frame stands on all support wheels.

Balancers with rollers assembled.

The suspension is fully assembled.

Three hydraulic pumps are attached to the engine, receive torque from the engine through the gearbox.

Sealing all joints.

Couplings transmit torque from hydraulic pumps to drive sprockets.

The caterpillar is assembled from tracks from a channel of 50x420x4 mm.

Leading asterisk.

The moment of tension of the track on the chassis.

The work of the welder.

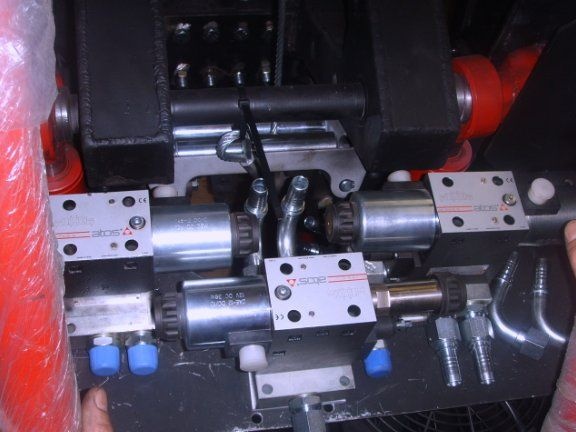

Waterworks.

Hydraulics assembly on the drive.

Electric hydraulic valves for control.

The drilling rig is up.

Manufactured parts.

All hydraulics are going.

The emergency control panel of the all-terrain vehicle and the drilling rig at the time of assembly.

The electrical circuit is going.

Remote control for the unit.

Wires go to moving parts.

Everything is assembled in corrugation.

The work of an electrician.

The engine started to run. video

The machine left with the garageNow finishing and painting.

In the video run-in.

Tracked all-terrain vehicle "Termite T-3 Hydro". video.

.

The entire group of builders of all-terrain vehicles success.