The author of this all-terrain vehicle is seriously engaged building similar machines and has extensive experience. Therefore, selling your previous all-terrain vehicle, he decided to start building something more unusual and interesting. So began the creation of the all-terrain vehicle Smolensk.

The main materials, mechanisms and units used in the construction of the machine:

1) Wheels of the brand Arktiktrans, size 1450.

2) The internal combustion engine was borrowed from a VAZ 1600 with eight valves and an injector, the approximate power of the unit is 82 liters. from.

3) The gearbox is also taken from the classics of the domestic auto industry.

4) To implement side-turn The mechanism was acquired differential from KAMAZ.

5) The rear window of the VAZ 2109 is heated, as the windshield of an all-terrain vehicle.

6) Brake discs from infinity 320 mm

Consider in more detail the assembly process of the all-terrain vehicle.

After the author collected all the necessary materials for the construction of this model of an all-terrain vehicle, he proceeded to full-scale turning operations.

Since this is far from the first project, and in general the construction of all-terrain vehicles for the author is more than just a hobby, he has at his disposal specialized equipment on which the basic work on turning business was carried out.

Below are pictures of the machines:

Regarding the engine for the all-terrain vehicle, the author was thinking about two options: either the Niva engine or the VAZ. The engine from the Niva is a bit more powerful than its competitor. However, VAZovsky was still installed, since the difference in power is not so great, and the engine’s mileage from the VAZ is only 1,600 km. Also, the existing injector will maintain stable engine operation at low speeds, and this is important enough for an all-terrain vehicle.

Also, a windshield was installed on the car, since it used to be a rear window, in order to protect against fragments, the author decided to tint it slightly. This method is quite suitable, according to the author.

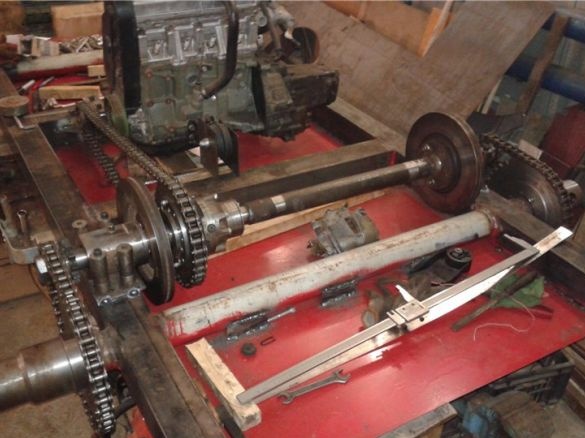

Several installation schemes for components were considered. One of these is: an internal combustion engine in a compartment with a gearbox installed along from the primary drive, and then it will put a CV joint with a cardan shaft and a rear gearbox.

What exactly is this circuit good for? It allows you to significantly reduce the width of the occupied space, and from turning operations it will only require processing of the sprocket shafts, bearings and brake disc flanges, which is not much. However, such a scheme has a significant drawback: the trunk will be occupied, which will reduce the amount of cargo carried.

After identifying the main directions of construction and processing of most elements, the author created an all-terrain vehicle frame and proceeded to manufacture disks.

Frame assembly photo:

For the manufacture of the frame, a 100 by 100 by 2 format pipe was used, by welding such pipes, axes were constructed that are visible in the first photograph, and they are already interconnected by the square principle.

And here is the finished discs:

Speaking of wheels, it should be noted that in the future it is planned to pump out the engine with pneumatic circulation.

The manufactured disk together with the hub are welded into one mechanism, and the axis and bearings of the hub are mounted on the frame, respectively.

Since the all-terrain vehicle is off-road and will be operated in harsh conditions, moisture / dirt can wear out some parts of the mechanisms, so the air valve is made of stainless steel.

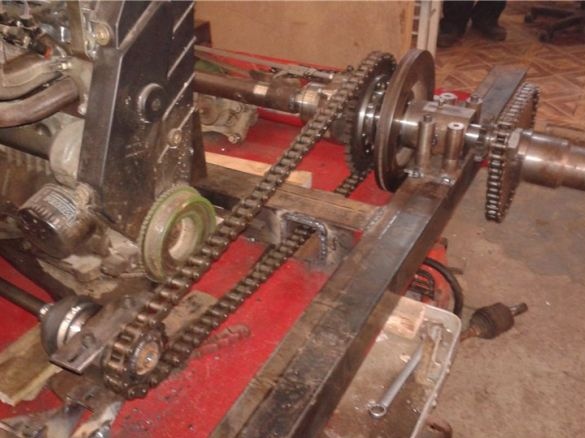

As you can see, the axis of the wheel in this case is a round pipe, on which the bearings are worn, and then the disk. The drive star itself is much smaller than the tire. This helps to avoid contact during maneuvers, since the star does not go beyond the disk, and therefore is protected from deformation. The only drawback, perhaps, is that the chain is only five centimeters from the tire, but if problems arise it can be eliminated.

Also, brake discs with a diameter of 320 mm were installed. Speaking of rubber for wheels, the author really liked the height of ArcticTrans hooks. In addition, there was a pleased generous offer to buy it, since it did not quite fit the previous owner.

A motor drive with a movable driving sprocket was used, and the tensioners were installed only on the rear long chains, since the front ones are quite short and do not need such a device.

The author tried to set a fixed star, but in this case, an additional tensioner would have to be made on the front chains, and this would have required more time. In addition, the effect of the lower sprocket, which raises the lash, is very good. The chain below the body does not fall.

In general, as the all-terrain vehicle was built, the author identified only one serious problem - a huge number of turning works. Turner only took 2 months of work to fit the parts.

Stars from the engine 11-32-11-40, the transfer took about three bays of 5 meters each.

The main elements were fixed using the guest bolts of the eight, their advantage is that they work exclusively on the cut, this will add strength to the chassis. The chassis itself turned out to be very heavy, in particular of course due to massive disks.

Another rather interesting way was applied to increase reliability. Since the landing on the hub is made on the star itself, the loads during movement are not transmitted to the bolts, which further reduces the chances of their failure. The only moments when the bolts are under load are braking and torque from the engine. Also, a hole was drilled on the side of the hub, it closes the tap.

After completing technical work with the chassis, the author proceeded to skin the all-terrain vehicle.

The metal used to sheathe the sidewalls of two millimeter thickness.

Video test machine:

ATV author: assistent