The construction of this all-terrain vehicle took only four months. The author wanted to get a small, maneuverable, and most importantly quite functional pneumatic all-terrain vehicle, which also must be able to swim. Also, a considerable factor for the author was the reliability and simplicity of the design of the all-terrain vehicle.

Elements of parts and structures used in the construction of this all-terrain vehicle:

1) Jupiter 5 internal combustion engine with forced cooling.

2) CPD reducer

3) Coupling from vases 2108

4) Chains for the drive

5) Cameras from Maz in size 320 by 508

Frame dimensions:

Length 230 cm

Width 100 cm

Height 30 cm from the bottom.

The all-terrain vehicle is capable of carrying up to three people.

The mass of the car is about 500 kilograms.

Ground clearance 60 cm

If the all-terrain vehicle is not heavily loaded, the height of the waterline passes along the axis.

Consider in more detail the stages of construction of an all-terrain vehicle.

To begin with, the author decided to assemble a frame. A profile pipe with dimensions of 20 by 40 by 1.2 was used, it was from it that the main bearing part of the body was made. The frame of the structure was made of a pipe 20 by 20 by 1.2 and 10 by 10 by 1.2.

The bridges from the classic vase were cut in order to make hubs out of them, and a support bearing was also used. In turn, the semiaxes were machined under the flange 42 of the tooth star with a pitch of 8 mm. Since the all-terrain vehicle must float, then, accordingly, the entire assembly was sealed.

For the same reason, the boat body itself was sealed with rivets and 0.5 mm thick sheet metal.

Actually it is this frame that makes the all-terrain vehicle so fast and easy to build. The author had neither special knowledge in mechanics, except general knowledge, nor experience in the construction of such units, but minimalism and calculation made the design really solid and reliable.

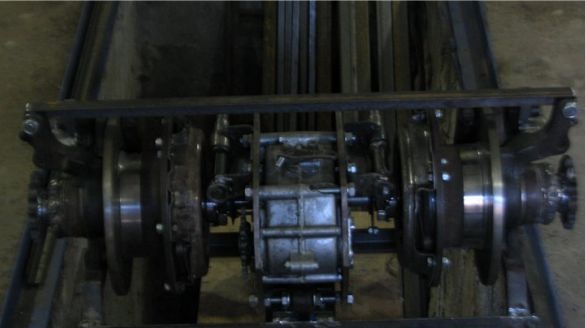

Assembly on a subframe of a separate unit:

The differential is disassembled, and in its case there are input shafts, knowingly adjusted to size using turning operations.

After testing with water, it was noticed that water accumulates in the chain tunnels, there is not much of it, but this means that there is no tightness of the case, since no leaks from the gearbox or engine were noticed. Since there is very little water, it is difficult to search for a small hole and the author decided to simply cover the main elements with covers, as well as to make a kind of drainage of water using special holes that are closed with screws.

Then the author began work on the wheels of the all-terrain vehicle. A disc and a basket from the VAZ 2108 were used, as well as a hub with a grenade, a fist and two disc brakes. It was decided to use one of the brakes as a kind of flywheel.

The gear ratio from the grenade to the shaft is two, and the shaft to the hub is already three.

Parallel planes on the upper and lower covers were centered. To do this, the author drilled holes on one axis through the pin. it is she who is the axis of rotation of the semiaxis. A stocking with a bearing is attached to the top cover. A centering sleeve is inserted into the stocking just under the diameter of the stud.

Work was also done with the bottom cover. A steel plate with a cage was laid in which a second bearing with a centering sleeve, and only then the whole structure is inserted through the pin. The result was a pair of bearings on the same axis in parallel planes, with the same distances between the plate and the hub in all nodes, of which four are respectively wheels.

It is long from a board to the plane of a semiaxis and a disk of a wheel about 230 centimeters turned out.

wheel sizes are as follows:

Diameter 1100 mm, width 40 centimeters. the complete wheel weighs only 27 kilograms.

The device is quite easy to go ashore or ice, as it is light. The possibilities of its use for both hunting and fishing are very great.

Photograph of the second pillow block, the axle shafts were trimmed and weld-in to increase strength.

Then the structure was tightened with nuts.

As can be seen from the photographs, a star was bolted to the flange and welded for reliability. The flange itself goes to the shaft key. Then the flange is tightened with a nut.

Using a transition pipe, a star was attached to the CV joint, and then welded under the washer:

Engine Photo:

The main motive for using such details for the author was their availability. And I would not want to order parts in case of a breakdown from Moscow and wait for them for several months. In addition, a similar approach to building very cheap, for this reason there is no electric starter.

From the leading star there is a transfer to prom. shaft, and with it the drive is already on each wheel.

Direct Drive Photo:

Tests were made all-terrain vehicle. When loaded with an all-terrain vehicle, with three passengers approximately instead of 250 kg, various tools and provisions, with a total weight of 70 kilograms, the following was revealed. When driving over rough terrain, the traction is noticeably not enough, so you have to go at higher speed. than it is necessary. That is, to solve the problem, the author simply unwound the engine.

IN the garage manipulations were made with the gear ratio of the engine and gearbox. With the new setting of stars under the maximum possibility of using a gearbox, it became much better in draft.

When driving, the first gear of the engine works as low, this is enough to overcome various bumps and bumps. You can watch more details in the video, which are located at the end of the article.

The second and third gears are already used on roads and flat surfaces.

In principle, the weight given in the example, the author considers optimal for an all-terrain vehicle, that is, under heavy loads, should be used trailer, since it is both simpler and more reliable for the safety of the all-terrain vehicle. Still, the trailer is both efficient and safe, so in the future it is planned to build it for an all-terrain vehicle.

After a run of approximately 200 kilometers, star wear is not observed. Chains are consumables, easily replaceable and inexpensive, but even their replacement was not required, although they stretched out a little, about ten millimeters. Thanks to the installation of floating tensioners, the chain sags from such a stretch are not observed at all.In general, the author believes that good lubrication and keeping chains clean is the key to their reliability.

The gear ratio was thoroughly adjusted, the exact numbers will be given below:

From the engine to the gearbox, the gear ratio is one and a half, this is with two stars 14 and 21 teeth, respectively. then the gearbox СЗД 2, two goes from the gearbox to the shaft, and the gear ratio from shaft to wheel is three. With this setting, the all-terrain vehicle behaves excellently.

It is especially comfortable to drive at a speed of about 35 kilometers per hour, the control and comfort on the road surface is the best. Although it is possible to fly over rough terrain for 40 km \ hour, the only thing that it is difficult to enter turns or rivers is speed, since the all-terrain vehicle drifts a little.

But for an all-terrain vehicle, the minimum speed has always been more important, it is equal to three kilometers per hour.

Typical wheel pressure is 0.16 kgf / cm2.

Video with an all-terrain vehicle:

The author of an all-terrain vehicle with the nickname "cap" from Krasnoyarsk.