All terrain vehicle built for trains for hunting and fishing in marshy areas. It was built as a kind of addition to existing models. The all-terrain vehicle must accommodate at least three people, as well as transport all the necessary equipment for hunting, as well as a tool.

What mechanisms and details were used in the construction of this swamp:

1) GP gas 71

2) complete Oka.

3) Wheels used ИЯВ-79 from Т150 stripped.

4) Internal combustion engine Kubota V1902

5) Seamless pipe 76 to 5

6) Bearings 180110

GP Gas 71 weighs 122.5 kg and has the following dimensions:

Length 560

Width 560

Height 300

Let's consider in more detail how the all-terrain vehicle was built side-turn type based on GP Gas-71.

To begin with, the author had to solve the main issues according to the all-terrain vehicle scheme. It was necessary to choose a four or six-wheel base. It was also necessary to calculate the engine power necessary for a comfortable ride. Since it was possible to install both the engine from the Niva and search for a more powerful one from a car with rear-wheel drive, this would solve the problem of turning the engine over and welding. The same question was about installing final drives or still use the transfer case and gear reduction scheme.

The main incentives for choosing the all-terrain vehicle all-terrain scheme were:

In the first models of all-terrain vehicles collected by the author, the weaknesses were precisely in the gouras, razdatki and half shafts, in the side-turn he would try to avoid this.

In addition, with such a turning pattern, maneuverability is much better.

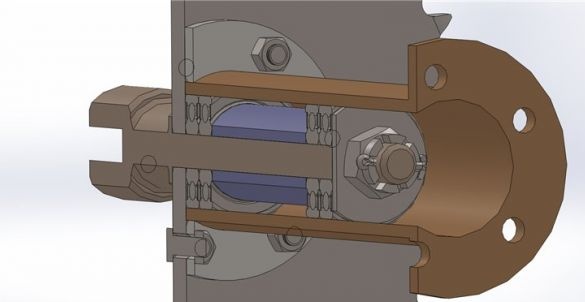

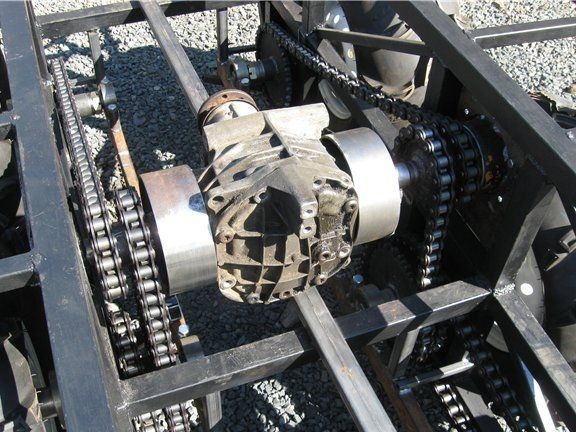

Here is the final drive gearbox and the reduction gearbox:

Using a 6 by 6 scheme, you can build a more comfortable, and most importantly more capacious all-terrain vehicle. In addition, it is quite easy to arrange all structural elements, in particular the engine and gearbox, there is no need to do everything too closely. And this in turn will provide easier access to parts when repairing or conducting a technical inspection of the machine.

Another important detail is that on such an all-terrain vehicle you can lose up to two wheels and easily continue driving.However, the author nevertheless leaned in the layout of 4 to 4, due to the fact that the wheels were chosen rather reliable, and the dimensions of the future all-terrain vehicle make it possible to put up to three rows of seats on two axles.

Then the author began work on the semi-axes for the GP, inside, during the analysis, a gear was discovered, which was quite easily removed. Therefore, it was decided to make a transition under any common axis that the author can get.

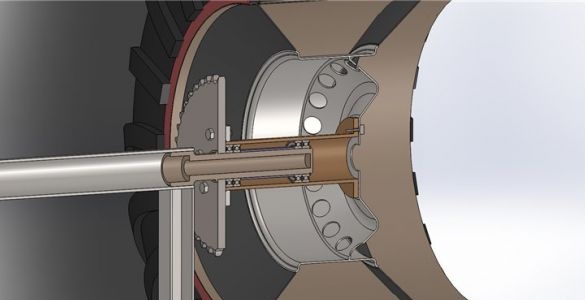

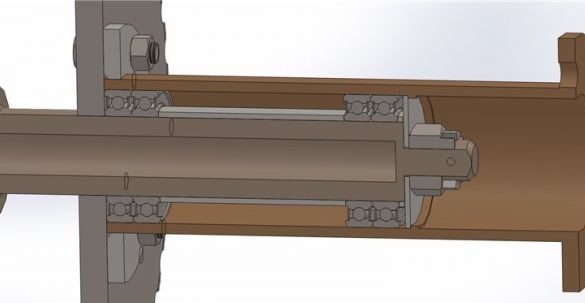

This is how the implementation of transmission using chains will look like:

As an engine, the author considered the following options: a 1.6-liter diesel engine from Volkswagen, it is quite affordable and easy to handle; Opel 1.3 CDTI or Renault 1.5 TD they are pretty similar, but a little more complicated than folz due to more electronics.

In principle, the author could use lawn driveshafts to connect the GP to the sides, but still preferred to grind a "pear" for connection with a gear clutch. This decision was made due to a more reliable fastening. In addition, the dimensions of the cardan when using such engines are quite impressive and the clutch looks much more compact.

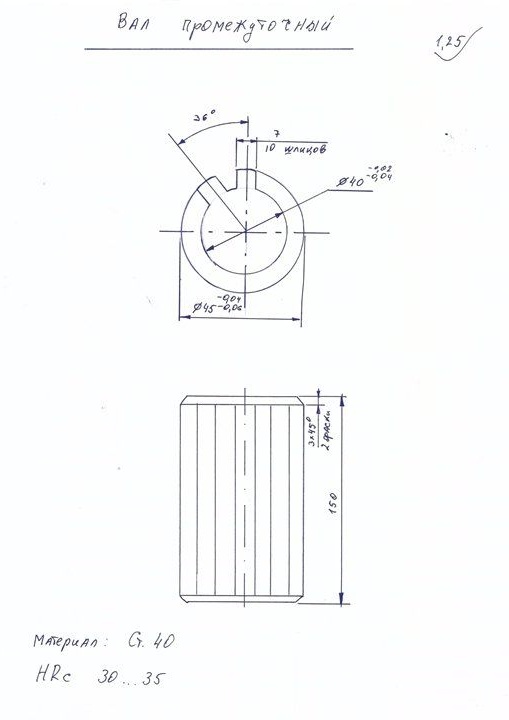

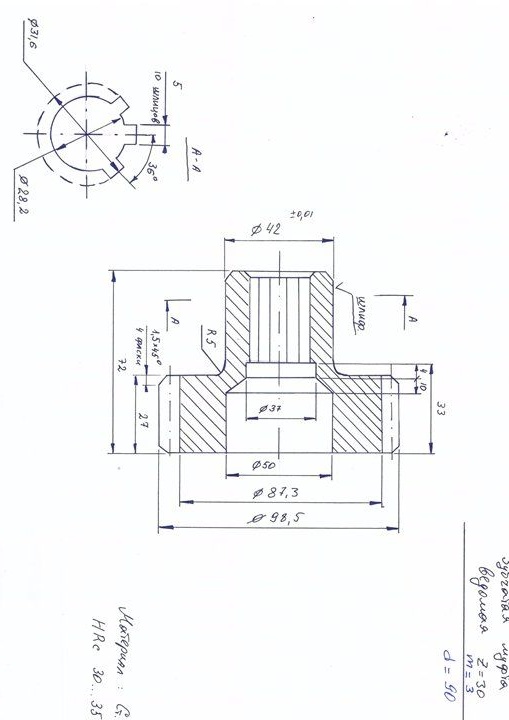

The following will show the components for the GP from Gas-71:

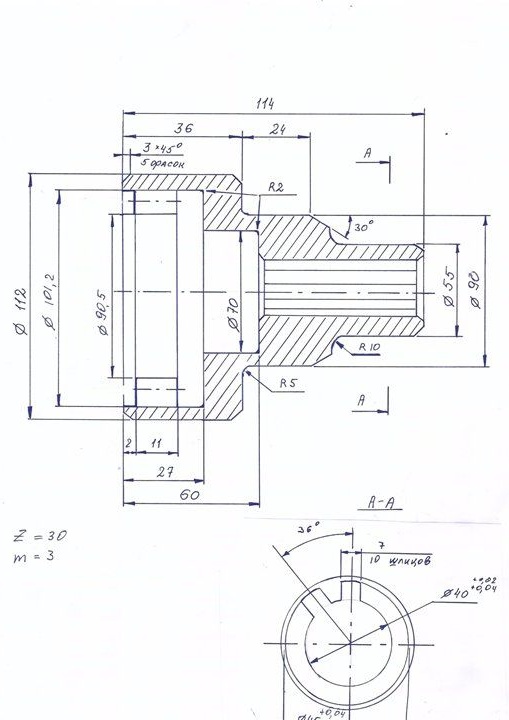

This is how the intermediate shaft looks from the pear to the final drives. It drilled a hole with a diameter equal to 25 millimeters.

And here the driven gear, and spline for landing on the shaft from the UAZ, due to the fact that the final drive from the army bridge, which was cut off, was used.

And here is the so-called "pear". The author did not write down the exact size, but proceeded from calculating the module x formulas for the number of all teeth plus the necessary clearance in the joint to enable folding of the coupling. moreover, the tooth gap is not large, only a couple of dozen.

Then the wheels of ИЯВ-79 from T-150 construction equipment were prepared.

Then the author proceeded to the preparation of the wheels, namely, their facilitation by peeling layers.

Kubota V1902 engine was also acquired, one of the most reliable units, although it weighs and is quite large in size.

After testing the engine, it was revealed that there are no problems with it, it starts easily and does not smoke. The only problem is the size and weight, because when placed with the box it will be located back to back, and the all-terrain vehicle will have to be made stronger, since there is overload.

In the meantime, work continued on the stripping of the wheels, since it was not an easy task to rip off the INB-79, the author approached this thoroughly. The advantages of these wheels compared to the rubber from VI-3, which was originally planned to be installed, is that the INV-79 is much softer and lighter.

As for the sizes, the diameter is 1300, and the width after pumping will be about 600. Moreover, the landing can be stretched to 50 centimeters quite easily.

The width of the wheel is quite difficult to measure in an inflated condition, since the rubber is very soft, and so goes under about 55 centimeters.

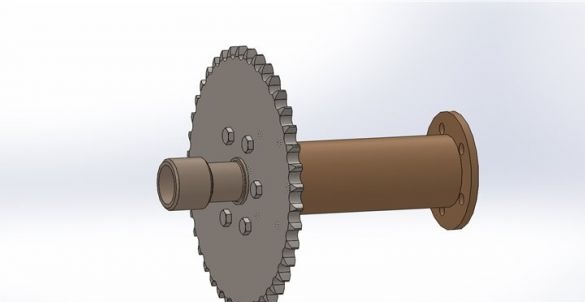

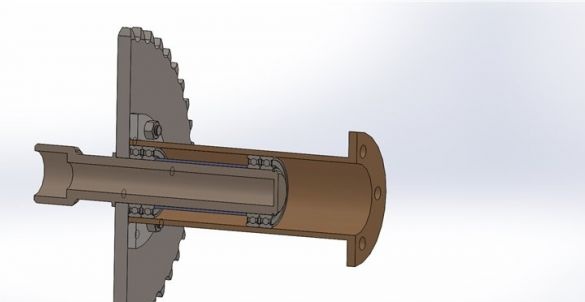

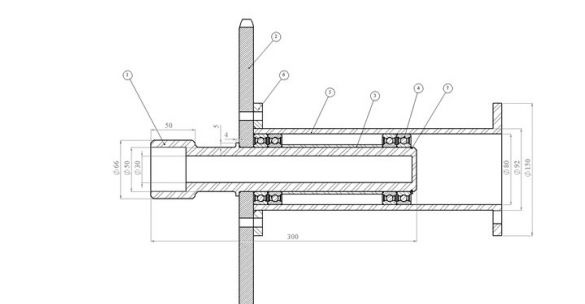

Further, the author began to manufacture the hubs, which in turn was no less laborious.

The package of bearings itself keeps the star from being displaced from the left, which abuts against the shoulder of the axis. On the right, there is a circlip, it is under pressure from the packet through a pipe that is dressed on the axis.

The dimensions of the axis: diameter 50, landing 70, and a wall thickness of 1 centimeter.

Moreover, this whole mechanism is inserted into a seamless pipe 76 by 5 sizes. Four bearings 180110 were used.

It shows how it looks in practice:

And here is a drawn version using a nut:

The oil seal is not used since gas pumping is not yet planned, and everything is covered by dirt with a washer and a star. Oil seals may be installed later, when the author proceeds to the exterior of the car.

It is also planned to use a 7510 bearing with dimensions of 50 to 90. A 1.5 mm bead will fall under the bevel of the bearing, so a wide washer was installed. And between the washer and bearing an adjusting ring is installed.

After finalizing the main nodes, the author built trailer for an all-terrain vehicle, in it it will be possible to transport not only new modelbut also old cars.

And here are the photos the garageworkshop where all-terrain vehicles were going:

Ready ATV:

All-terrain vehicle author: Novel with the nickname "trofkir" on .