Interesting model all-terrain vehicle with two axles on a side turn. All terrain vehicle going for hunting and fishing trips, so it should easily pass forest roads and swamps even in the off-season, so the side turn is a good solution for the reliability and compactness of the design of the machine.

The mechanisms and materials used in the construction of the all-terrain vehicle:

1) 76 to 3.5 pipe for the frame

2) Chains 16V-1

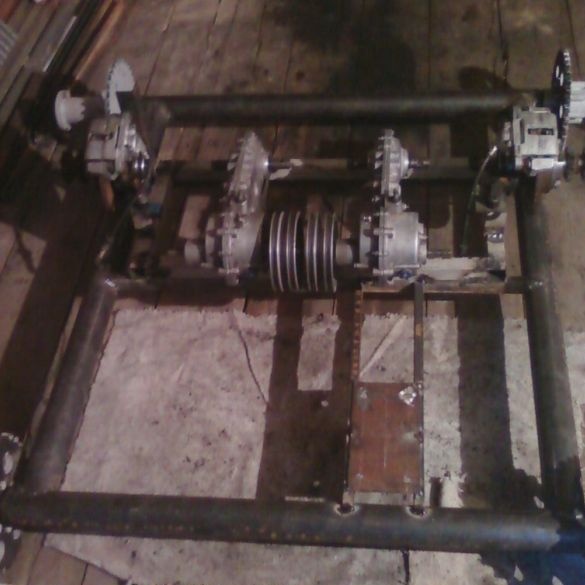

3) Gearbox from Motoblock 5B-S

Consider in more detail the construction of an all-terrain vehicle:

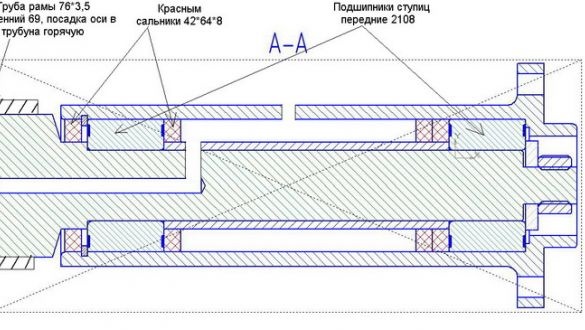

This is how the hubs are made, there is swapping through the frame, the installation of fittings is planned:

The frame is made of pipe 76 to 3.5, for the transmission will use the following chains:

The sketch of the hub was slightly modified in the design to find a place for the seals:

Regarding gear ratios, there is the following distribution: from the engine to the gearbox 1-1.45, lowered 1 to 24, high 1 to 11, rear 1 to 17. On the gearbox, the star of the 9 teeth goes to the follower 35 tooth. The maximum speed is about 12 km \ hour

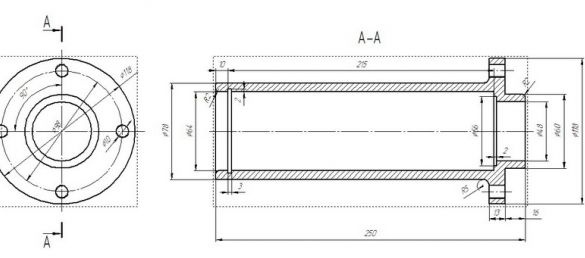

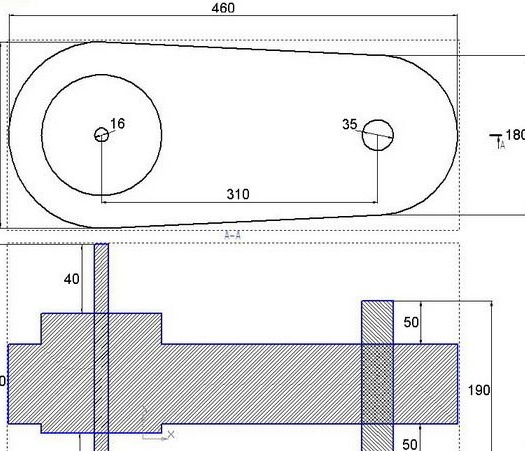

Here are the dimensions of the gearbox itself:

So the hub will be made, plus paging holes will be made:

Bearing landing and lowering:

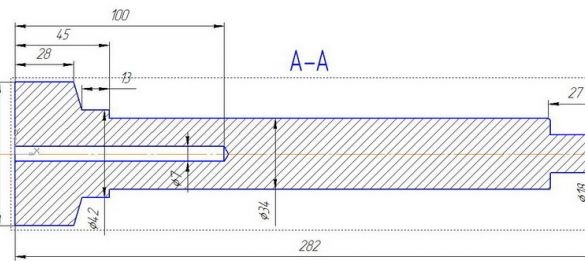

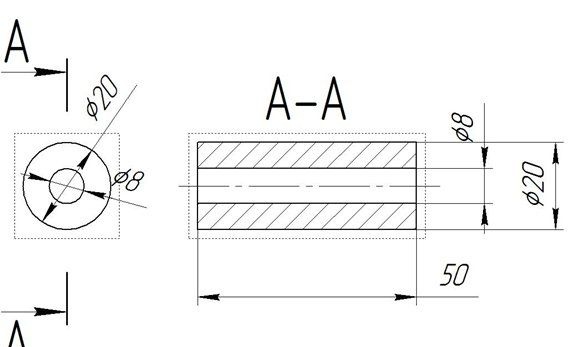

Next, the axis of the hub was made, steel 45 was used. The diagram does not indicate a channel under the air perpendicular to the axis. the size was also increased from 28 to 45 mm, lowering between the bearings. Diameter 20mm:

Then the author decided to start painting, and so the work was done on fastening the casing of the all-terrain vehicle:

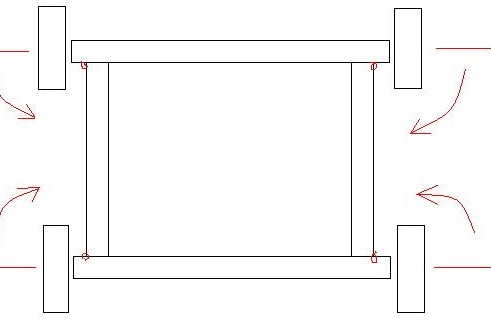

Since it was difficult to comply with the ideal design dimensions when cooking the frame, the author had to spend a lot of time on fitting and not all parts are sized according to the diagrams. The axles were pressed into the pipe for hot. When everything was thoroughly boiled, then each axis was taken away by 2.5 mm to each other. After installing the wheels, this became especially noticeable. It is planned to correct this error with a jack.

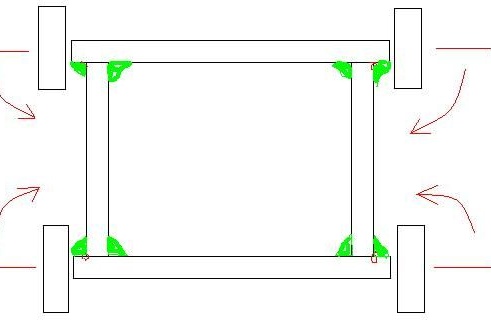

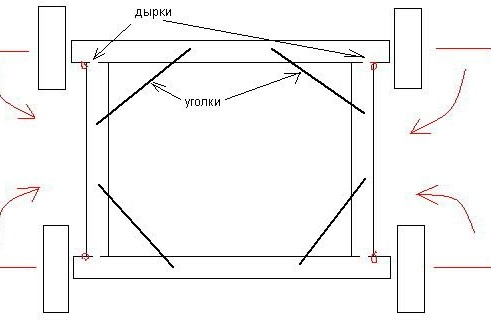

There is an option to weld by installing corners:

But even when installing the corners, there is still a skew, maybe the swap holes are to blame:

Correction work:

The swap implementation scheme looks like this, in the future it is planned to make centralized:

Two engines that can be used in an all-terrain vehicle, they are essentially the same power, but there are differences in fasteners:

An interesting new exhaust pipe was also welded:

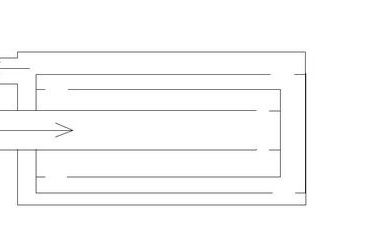

exhaust flow chart:

And here is the engine compartment after all the modifications:

Installed chain tensioner:

ATV cabin photo:

Expected wheels:

There was an idea to use boat valves with glass glue gluing on cameras. Very convenient in terms of swap-downs, sweeping takes a few seconds, and swapping is only 3 minutes. But after assembling two such wheels, one lowered it in just a day, which means it will have to abandon the idea of using such solutions and begin to search for new ones:

For pumping, a boat pear is used, so the nipples for it were made:

Here is the design from the inside:

Mounting driven stars on the hubs looks like this:

In total, six similar parts were welded to the hub, and the dimensions were changed upwards, that is, 10 were made instead of 8:

For three days, 72 kilometers were rolled on this all-terrain vehicle through a highway running through a river, clay swamp. As a result, it was estimated that only 16 liters of gasoline were consumed over the distance traveled, which fully satisfies the author’s desire. Given the conditions of the 16-liter highway, there is indeed a very small expense for this type of all-terrain vehicle.

The swap was implemented in this way:

The exhaust closes on the muffler using chopik.

Pumping is used quite often, especially in the off-season, when temperature changes from +20 to -15 degrees, which greatly affects the pressure in the tires. The normal pressure for trains turned out to be about 0.18 atmosphere, and its author is trying to keep it by swapping. After disassembling the nipples, the twist did not become so critical. Also in the trunk is carried a single boat, which is also very convenient to pump with exhaust. In the future, the author plans to switch to tubeless wheels and upgrade the swap control directly from the all-terrain vehicle cabin.

To combat tire rotation, the width of the discs was cut to 40 cm, teeth from the electrodes were also welded, and then the tires were seated using building sealant. Also, the author began work on the tires themselves, eliminated punctures and cuts using firmware awl and sealant.

ATV Test Video:

Design work was performed on the appearance of the all-terrain vehicle. It is planned to install an external transparent gas tank, as well as a simplified exhaust swap system. The performance of such a swap circuit is no worse than two reciprocating compressors, but does not require a battery.

In the process of opening the hunting season, the all-terrain vehicle was exploited a lot. Some breakdowns occurred, in particular, there was an overheating of the engine, opening the chain lock and a break in the nipple of the camera due to the rotation of the tire. But the exhaust pumping helped me get to the repair site. All wheels were pumped up by 0.1 atmospheres. As a result, about 10 liters of fuel were spent on 42 kilometers of track, which is very little for an all-terrain vehicle.

The author of the all-terrain vehicle: Alexander from Yekaterinburg with the nickname "Alex-R".