This article describes how the radio model hovercraft with minimal cash costs and shallow knowledge in the field of creating SVP.

The SVP was assembled at the department of the Saratov State Technical University by its students. Photos and videos were taken on a HTC Mozart camera.

Project idea

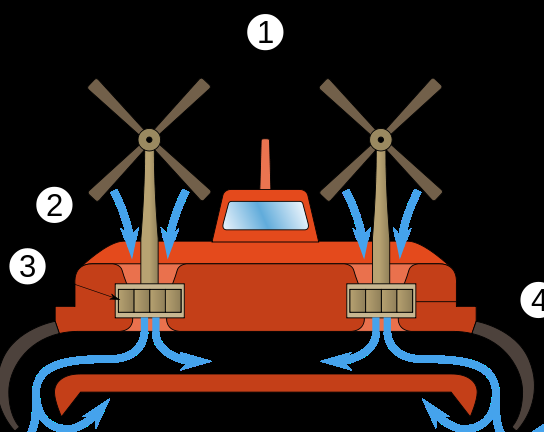

This kind of crazy idea was reduced to creating an SVP model controlled by a radio signal. This SVP is able to fly over small obstacles (as WIG or even C-class ekranoplanes do). There are plans to install a vision system, which itself will notice obstacles and help overcome them. This system will also be able to identify and follow their own SVPs. In case of successful completion of the project, an SVP group will be released with the ability to control only one of the vessels.

Necessary materials and equipment

To create a hovercraft, the following materials and equipment were required:

penoplex - 2 (3) pieces (500 or 750 rubles)

polystyrene - 2 spindles of 1.5 meters (total 900 p.)

double-sided tape made of fabric - 1 piece for 50 p.

glue "Titan" - 1 piece 80 r.

medical oilcloth - 1 (3) pieces 100 r. (300 r.)

speed controller - 2 (3) pieces 2540 p. (3810 p.)

engine - 2 (4) pieces for 3110 p. (6220 p.)

battery - 2 pieces for 2360 p.

propeller - 2 (7-10) pieces 300 r. (600 p.)

servo - 1 piece, which went to the authors for free

6-channel radio control - 1 set delivered free of charge

As a result, 15070 rubles were spent. at the maximum expenditure of materials. As you can see, the budget is small and it can even be reduced to 9940 rubles.

SVP assembly process

Initially, all the missing materials were purchased: 2 batteries, 2 engines, as well as 2 sets of propellers, glue, adhesive tape, and foam. And the authors had 6-channel radio equipment at the department.

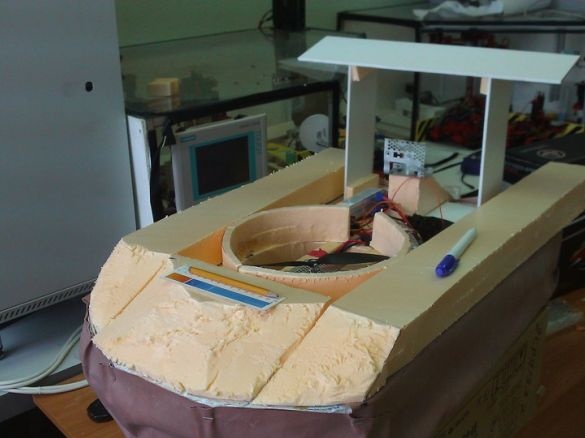

Penoplex was unmistakably chosen as the main material for the SVP case due to its lightness, strength, and convenience in giving a variety of shapes.

The creators revealed that the engine with the use of speed controllers even without air cushion when working at 50% perfectly lifted the body into the air.

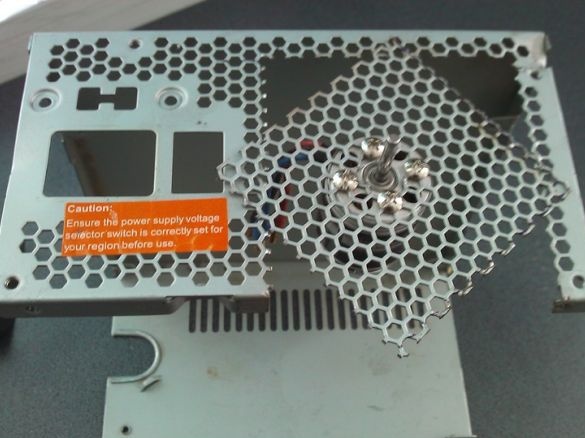

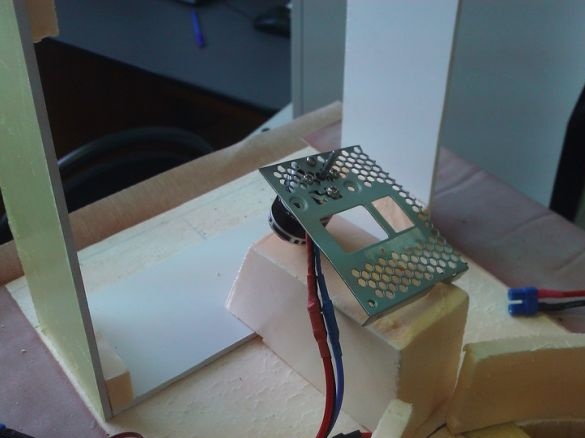

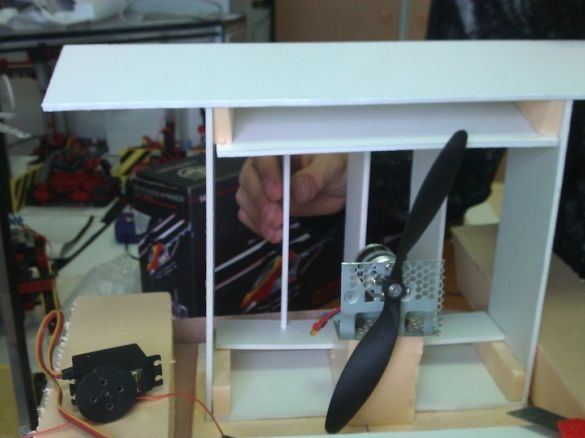

The holder for the engine was cut from a used case power supply unit.

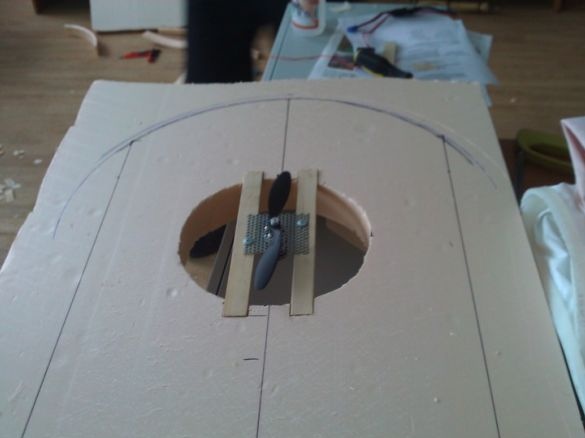

The skirt was made of a single piece, a slot was made in it in the middle (cut pieces of film to create a skirt did not fit).

The skirt was made according to the following principle:

The further process of gluing the bottom of the SVP skirt is described in the picture and video:

The tail of the vessel was made of polystyrene.

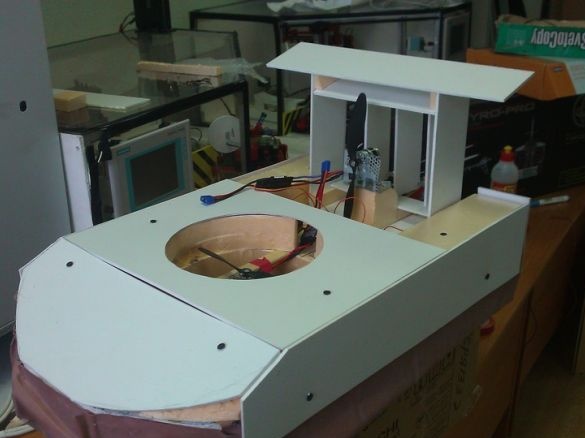

As a result, it turned out:

The remains of the hull were used to create a second motor.

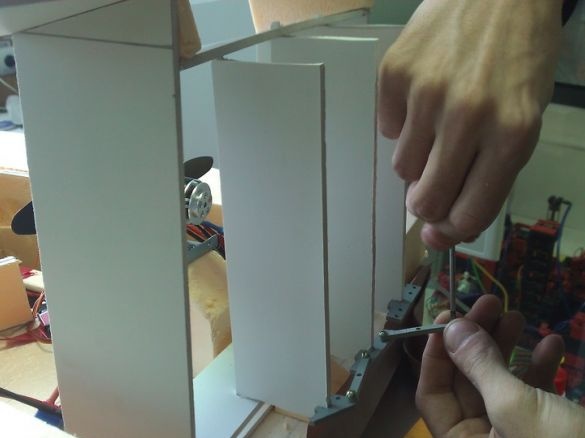

All components of the SVP were screwed with long screws to the foam. They hold very tight.

Finishing work on the penoplex, all the irregularities and shortcomings were hidden, tanks for the sulfur pipeline and batteries were cut.

Steering wheels and casing were also made of polystyrene.

The system that turns the steering wheel was created from the parts left from the old manipulator.

And currently, SVP is as follows:

Further improvement of the project

First of all, it is necessary to replace the main engine due to the fact that the old one, unable to withstand the load, burned out (the winding melted in it, the regulators stopped working, and the SVP stopped moving forward).

The weight of the SVP turned out to be small and only 35% of the engine power is required to inflate its skirt. Therefore, the authors plan to introduce the Kinect and e-box 3310A in the SVP, because they have enough power and space. Subsequently, they will fulfill the role of a vision system. After the SVP test drive in the open air, they plan to mount wings in it.