In good weather, a motorcycle scooter with a small engine capacity has always been in demand not only among young people, but also among adults. Since it was distinguished by its simplicity in management, ease and good speed. But unfortunately, when the cold comes due to the small diameter of the wheels, riding a scooter becomes very inconvenient, and in snowy weather, even wearing winter tires is completely unrealistic.

After studying various motorcycle magazines, it was noticed that there are caterpillar engines on sale, they can be installed instead of the rear wheel, which will lead to the transformation of the motorcycle into a snowmobile.

If you have like-minded people in this matter, then it is best to take a caterpillar from the Buran snowmobile (photo 1), it is perfect, since 4 suitable scooters will come out from one caterpillar. The cost will cost 2.5 times cheaper than the tracks taken from a motorcycle. But for one scooter it will cost too much.

Soon, having contacted the company, which is engaged in sets of movers, one not very wide track and a plastic ski without fastening were acquired.

No changes will be made to the basic design of the scooter, so that in warm weather you can always replace the installed tracks with wheels.

We purchase a driven asterisk from the Buran snowmobile in the store, 2 wheels from an ordinary scooter for children and 2 small wheels from a trolley, with roller bearings. Next, we put a wheel of a much smaller diameter instead of a driving wheel on a scooter, for example, from a sports one auto, in order to replace the gear ratio. This is done because in a scooter transmission, the gear ratio is usually calculated to operate it on excellent roads with an approximate speed of 40-60 km / h. Of course, when driving on snow, the load on the engine increases significantly and its power is most likely not enough, and such a high speed can be dangerous on slippery roads.

We take the drive wheel of the moped and cut out the brake drum with splines under the drive shaft, and to fasten the drive of a smaller diameter, drill a hole in the drum (photo 2).

In order to prevent the caterpillar from sliding off the wheel and slipping during movement, we make hooks (photo 3) from plastic water pipes, which in turn are inserted into the hole on the caterpillar.

It is necessary to make a bandage of the required diameter from flat roofing metal, fasten hooks on it using furniture bolts-grouse (photo 4), they should be at the same distance from each other and in a step that will correspond to the location of the caterpillar holes. Using the same bolts, we fasten the wheel, having previously put on a bandage on it (photo 5). We get from a regular wheel, a soft leading caterpillar sprocket.

Using M8 bolts we connect the leading sprocket of the Buran snowmobile with 2 rubber wheels from the trolley, we get a driven sprocket, and for the axis we take a stud with M10 thread (photo 6).

To make the frame of the caterpillar mover, you will need metal corners and square pipes (photo 7). The dimensions of the frame and the parts to be attached to it will need to be selected independently, depending on the track you have chosen and the brand of your scooter.

You can take a homemade ski out of wood or a plastic one from a children's scooter, attaching a metal undercut to the bottom so that the scooter does not lose control on an icy road. The ski must be fixed at the front fork of the scooter through a special rack. It will have 2 degrees of freedom of movement, due to which, when the scooter is tilted to either side, the ski will remain on the snow with its entire plane.

We install a wide platform under the legs and a small decorative shield for the front fork. For long trips in adverse weather, you must install a windshield.

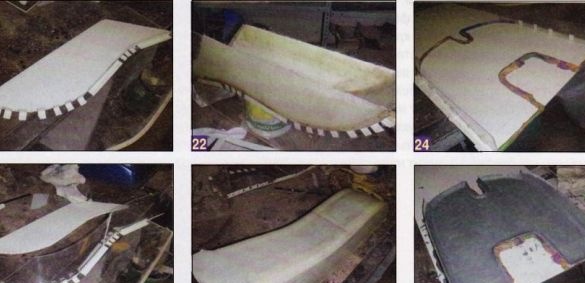

The standard body kit on a scooter is not very strong in high-degree frost and has small pockets, when the snow gets into them, the weight of the scooter will increase. To avoid this, we make a small casing over the caterpillar. To do this, take a piece of plexiglass, polycarbonate or other plastic that we need in size and carefully cut out the side of the casing.

We shift it to a large sheet, it will serve as another matrix wall and with the help of hot-melt adhesive around the perimeter of the sidewall we fix the plastic corners. Cut off a strip of flexible and preferably thin plastic, the width of the planned casing. Carefully assemble the matrix by gluing on the corners the previously made sidewall, bottom and large panel. All joints of parts must be smeared with plasticine.

Next, we cut the fiberglass into pieces of the size we need, carefully smear them with epoxy and fit it tightly into the matrix. After about a day, it is necessary to remove the matrix, and cut the resulting casing along the contour, removing all excess fiberglass.

Using the same technology, we make a foot platform, just add a little silver powder to the epoxy for better viscosity and color.

Snowmobile scooter test video: