Pretty simple and cheap to build all-terrain vehicle based on the oki was made by Leonid from the city of Nyagan. The all-terrain vehicle is capable of speeds of about 50 kilometers an hour, as well as swim across water obstacles. the machine was made mainly for forays into remote areas of the forest for gathering.

To assemble such an all-terrain vehicle, the following parts and materials were required:

1) Body from the car Oka

2) profile pipe for frame assembly

3) Internal combustion engine VAZ 1111

4) most of the chassis from the Niva 2121

5) TIRES SHAINA

6) Steering from vaz 2109

Consider in more detail the work done on the all-terrain vehicle.

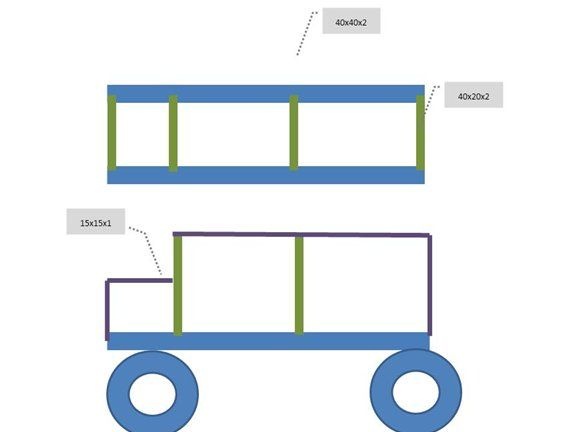

To begin with, the author decided to make the frame of the future all-terrain vehicle. the frame was made independently of the profile pipe available from the author.

The frame manufacturing scheme is shown below:

Here is the front axle of the assembled all-terrain vehicle:

Set transfer case:

Mounts were removed from the bridge from a Muscovite to install springs. springs were installed from the Muscovite 412 with stepladders, for this they were previously measured and overcooked. Initially, the author planned to make a spring suspension, as is customary for all-terrain vehicles with a small weight of the oka type, but decided that the springs were still more reliable, since for the springs it was necessary to complicate the frame under the course of the springs and put more salenbloks for mounting. That is, the main factor in favor of the spring suspension was simplicity and reliability.

After the main assembly, the author proceeded to test the car. In the course of testing, minor improvements are also being made, in particular, deficiencies are identified and eliminated, work on the appearance of the machine continues, the suspension system is improved.

The weight of the all-terrain vehicle was about 800 kilograms. The all-terrain vehicle has the following dimensions: the base length is 210 centimeters, the width is 208 centimeters, the length of the all-terrain vehicle is 360 centimeters, the height is about two meters, the ground clearance is 40 centimeters.

Paintwork was carried out, as well as foam was installed under the bottom for greater buoyancy:

For the same purpose, the camera can be mounted on two straps in front of the all-terrain vehicle, with this approach you can not worry about the stability of the machine on the water.

For a short period of operation revealed several problem areas of the all-terrain vehicle. In particular, the upper plates of the front springs bent, so the scarves will be installed. There were still problems with oil, over 50 kilometers the oil level dropped significantly, since the engine was purchased in excellent condition, then most likely this is not the case. In addition, oil smudges were not found anywhere. the reason lies in the wet filter after overcoming water obstacles. The holes in the top cover on the housing were sealed to prevent the filter from getting wet. Running did not reveal any problems.

The chassis has no breakdowns, mainly due to the low load coming from the wheels. such wheels fit perfectly into the Niva suspension concept. however, for the all-terrain vehicle itself, it is desirable to install larger wheels, since the small diameter of the wheel, this, in turn, is a small amount of air in the tires, and therefore it is necessary to go to tricks in the form of foam and additional chambers to overcome water barriers. Also, the installed wheels have a too weak tread, which in fact does not work in the mud. over 350 kilometers of track all the spikes on the wheels shoot, father-in-law tires will wear out pretty quickly. A felled log becomes a difficult obstacle to overcome.

But there are pluses to this design:

The suspension travel is very soft, since the wheels are still wide, the all-terrain vehicle does not sit on the bridges and walks confidently along the clay.

These wheels eliminate heavy loads on the axles, which increases their service life. Well, the most important plus is the price, since the axles of the chassis are quite cheap, but it fits exclusively with this type of wheel.

If, for example, you install wheels with a diameter of 1300 or more, you will have to redo the chassis, in particular, install axles from UAZ. Therefore, the 1,300 authoros available to the author are still idle, but in the future it is planned to replace the bridges with UAZ and, accordingly, rubber.

In the meantime, in order to increase traction, it is possible to attach belts from oil pumping units to the SHAINA wheels, but not the fact that the transmission can withstand such loads. Therefore, the author travels as is, as he fears for the axles and front gear. It may be possible to install a compensating coupling on an all-terrain vehicle until it is completely modernized.

Weaknesses of the all-terrain vehicle's suspension were also identified, after hitting a log at a speed of 10 km / h, the steering rod was bent, which subsequently failed. The rod was replaced and reinforced with a rod f 10 on both sides for reliability.

as for the all-terrain vehicle driving through marshes, it unfortunately fails, but it’s not about the wheels, it’s more about the terrain. In any case, the all-terrain vehicle is able to independently leave such situations when the lock is turned on.

The gearbox is enough from oki, even a lower one is not required. Steering rods, by the way, were installed from the frets of the nine, but the author plans to remake and replace them with Nivov. the steering is quite light, but there was a mistake in the corners relative to the bipod.

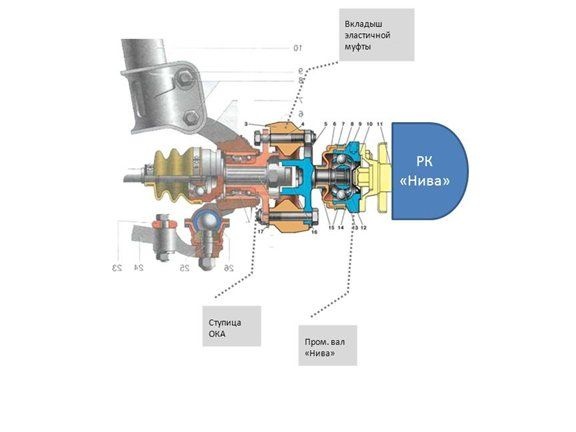

The connection between the oki engine and the steering column from the cornfield is shown below.

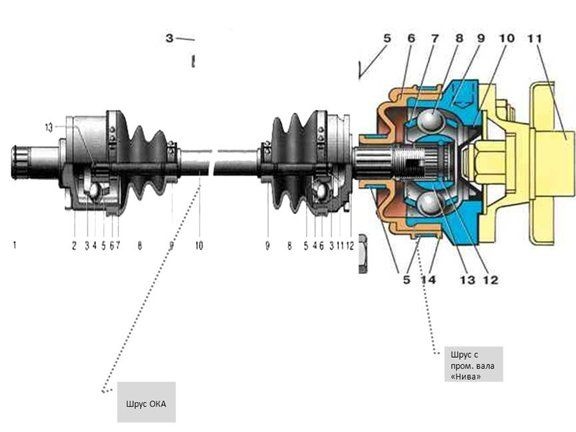

The flange is machined under the vase propeller shaft, for this an intermediate Niva propeller shaft is taken, a small CV joint with studs is removed from it. RKP goes under the flange, the spline of this CV joint is the same as that of the semi-axis from oki. A propeller shaft is made from the inner oki joint, using the axle shaft and a small Niva joint.

It turns out something like this, do not forget about the bearing, it is necessary to reduce the load on the transfer case.

From the transfer case, it is already transferred to the bridges as usual:

Photos of the off-road vehicle:

The author of the all-terrain vehicle: Leonid from the city of Nyagan.