The all-terrain vehicle made on the basis of components of vases from steel profile prof. flooring. He is able to reach speeds of up to 20 km per hour on land and 2 km per hour on water. The weight of the car is 330 kilograms. The all-terrain vehicle is made as resistant to capsizing as possible. A-76 gasoline consumption is 1.7 liters per hour.

Materials and parts used in the construction of this all-terrain vehicle:

1) steel profile and prof. flooring

2) hydraulic steering damper from Mercedes.

3) maz cameras

4) gazelle chambers

5) classic vase wheels

6) gearbox from VAZ

7) D-300 engine

8) vaz bridges

9) VAZ cardans

Consider in more detail the design features of the all-terrain vehicle and the stages of its construction.

The rollover protection is made in such a way that at a critical moment the wheels of the car go into slip and prevent the car from tipping over. However, because of such a wide base, the all-terrain vehicle has a large turning radius of the order of nine meters. In order to reduce weight, the steering mechanism was simplified and lightened as much as possible. However, in order to increase driving comfort and remove shaking, a hydraulic damper from the Mercedes was inserted into the steering wheel.

The frame is critical at the junction of the driveshaft with the front axle flange. The effort is not strong, therefore it is permissible to continue moving up to five hours to a row without fear of overheating.

Below are photos of the fracture node:

Wheel disks were made of a steel strip measuring 40 by 4 mm. the basis for the drive was the inside of the drive from a classic VAZ. The finished disk is equipped with flippers from cut chambers from a gazelle. The flippers are equipped with Maza cameras measuring 300 by 508, and on top of these cameras are the same but cut.

For greater integrity, the structure is tightened with bandages, which are fastened with hooks.

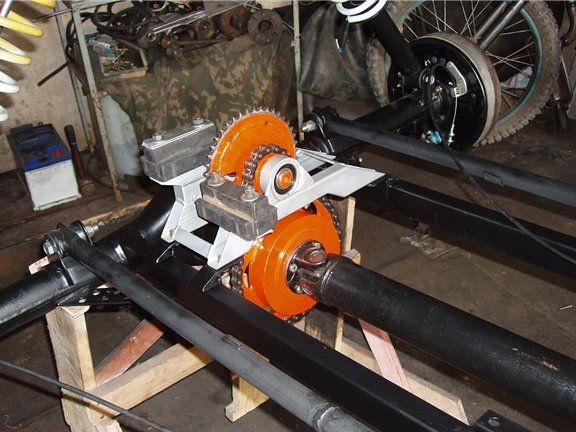

At the rear of the engine mount is a home-made transfer case with a chain drive and a braking device.

Here you can see the transfer gear and brake system:

The car It is designed for two seats, that is, the driver plus the passenger. also an all-terrain vehicle can carry up to 60 kilograms of cargo and at the same time keep perfectly on the water.

An awning is also installed, which can be quickly removed due to pneumatic stops from the rear door of a car. reinforced mirrors as well as a small windshield protect the driver and passenger from branches and wind.

The angle of rotation of the wheels is 25 degrees and is limited only by the angle of fracture of the front driveshaft.

The wheels are designed in such a way that it is possible to eliminate any malfunction without resorting to serious tools, the tires are removed and put on manually in 5-10 minutes, although often this is not even required, most punctures are eliminated by a plaster from the bicycle kit, and the deflated chamber is pumped up with an electric compressor.

Photo of disks made and installed on an all-terrain vehicle:

As you can see from the photo, only the middle is made of a disk from a vase.

According to the author, chamber wheels and a chain drive for light off-road vehicles are the perfect combination. Chamber wheels provide excellent cross-country ability, as well as all breakdowns associated with them are easily fixed on the spot. The chain drive is also easily repaired and the replacement of components is quite cheap.

Although for heavy all-terrain vehicles, cordon tires are undeniably needed.

The only minus of the chamber wheels is that in winter there is a similar deformation of rubber:

the reason for this camera behavior is not known, but in urban the garage the author did not have such problems.

Below is a photo of the rear suspension of an all-terrain vehicle:

From the rear suspension of the vases, longitudinal rods were used, their rubber silent blocks are able to provide the necessary mobility of the suspension, while holding it on the axis of symmetry of the all-terrain vehicle body.

The U-shaped frame is qualitatively bonded to the rear axle in such a way that it forms a single system with it. n

A pillow was used from the vaz engine, which is used in the central part of the frame mount and the rear suspension, for greater reliability it is fixed with two m6 bolts.

The following photo shows the mounting of the power plant frame to the engine mount, which is part of the rear suspension. Thanks to the installed pillows, vibrations are noticeably reduced, as well as noise. The whole system is bolted with m6 bolts and holds securely.

Photos of the ready all-terrain vehicle:

The author of the all-terrain vehicle under the nickname "Pasha 53" from the city of Veliky Novgorod.