Interesting model pneumatic all-terrain vehicle with front-wheel drive. All terrain vehicle It has four transfers and is designed for 2 people, as well as 250 kilograms of luggage. The all-terrain vehicle is capable of walking not only on land, but also excellently overcomes water barriers and has good buoyancy.

Materials and assemblies involved in the construction of this all-terrain vehicle:

1) UD-1 internal combustion engine with a power of 3 hp

2) sprockets for 11 teeth

3) 41 tooth stars

4) stars for 15 teeth

5) stars for 39 teeth

6) main details from M-412

Consider in more detail the construction of the main nodes of the all-terrain vehicle.

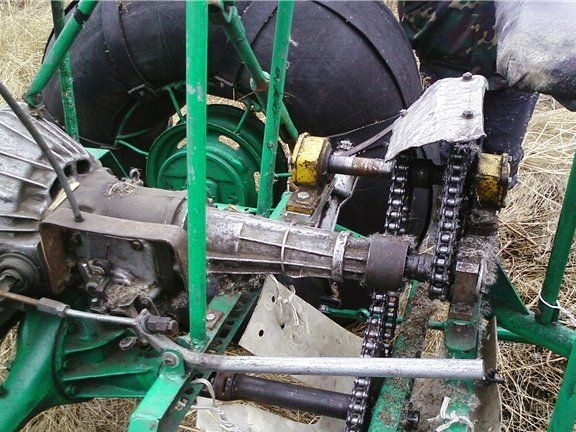

The transmission laugh is based on a front-wheel drive chain drive. To do this, stars with a dimension of 11 teeth were installed on the gearbox, stars 41 and 15 teeth were placed on the secondary shaft, and a star with 39 teeth was placed on the bridge. In the first gear, the all-terrain vehicle buries a little, but is able to move even on the fourth from a solid surface. Since the car does not have a large mass, in marshy areas it is often necessary to transfer the weight of passengers and cargo to the front axle for better traction.

Here is the gear shift mechanism:

In water, the engine of the all-terrain vehicle is muffled and further movement through the water occurs due to the flow and handy means, like on a raft. The engine needs to be switched off due to flooding of the all-terrain vehicle with water up to the flywheel.

A distinctive feature of this all-terrain vehicle is the ease of transportation, since the machine is designed as a designer and is easily disassembled, thereby placing in a small van or minibus.

The maximum speed of the all-terrain vehicle is 15 kilometers per hour, and the minimum is three. Connection half-frames taken from the junction of the arrows of a crawler crane. an automatic gas system is also installed on the all-terrain vehicle, due to the engine from the power plant. Fuel consumption is less than one liter per hour, even under difficult conditions of the route.

A folding seat for the passenger is made on the front axle of the all-terrain vehicle, and a tool box is also installed, this is done for the most part, in order to move the center of gravity closer to the front axle.

Then the more powerful Lifan engine of 15 liters was installed on the all-terrain vehicle. from. , and to improve the quality of patency on the wheels of the drive axle OI-25 rags were installed. Tires increased the cross-country ability of the all-terrain vehicle several times.

Yes, and the engine power is felt, in general, modernization significantly improved all the characteristics of this all-terrain vehicle. Below is a photograph of the installation of the Lifan engine on the all-terrain vehicle frame and its connection to the main structural elements:

The only drawback is the shaft play, which appeared after replacing the engine.

Then the author installed a generator to operate the electric pump, and a starter was also connected.

After modernizing the all-terrain vehicle, the author proceeded to its serious tests in difficult off-road conditions:

4WD has been completed.

It is planned to alter the all-terrain vehicle to four-wheel drive by installing an outboard propeller shaft with a CV joint and a rear axle.

There was a serious damage to the all-terrain vehicle: the rear propeller shaft was bent on a hard bump, but the all-terrain vehicle was able to continue moving on the front drive, but the frame could not withstand the load and burst.

A garter in the form of a wire was quickly organized in a vulnerable place of the frame, but this did not bring results.

The device was loaded on trailer and taken home for repair in a garage.

The frame is experiencing a serious load in only one place, so the author seriously began to search for the reasons for such a weak spot in the structure.

While the author was engaged in repairing the main units of the all-terrain vehicle, he himself was put in winter storage:

The rubber was previously removed and entered into the heat.

The machine is fully collapsible, which greatly facilitates transportation:

The whole structure easily fits in a minibus, the rear seat is removed, the bridge is also dismantled from the front for loading onto the bus:

The author faced the following problem: oil leakage from under the cover where the pulley is located, so it was decided to cover the gasket with sealant.

The variator was removed:

Due to the marks on the shafts, the cover was easily removed, the engine was cleaned, and the sensor responsible for checking the oil level was also removed. On the side of the engine, where the wire comes from it, there is a hole through which an oil leak has occurred, so it was sealed:

The double wheels on the front axle of the all-terrain vehicle are fastened by a conveyor belt and bolted to a nut by 6. If the chambers are weakly inflated, the belts can pile up, so you need to monitor the pressure in the chambers. A seat for fastening the belt is cut out on the tire; due to such a modernization, patency increases even more. Since the engine is still quite weak, the bridges are able to withstand a similar load.

When installing a more serious engine, you will have to redo the bridges, and therefore increase the mass of the all-terrain vehicle.

ATV Test Photos:

The author of an all-terrain vehicle with the nickname "Vitya" from the city of Novosibirsk.