In the literature for gardeners, various designs of "rigid" frames for greenhouses made of pipes and corners are widely represented. However, as a rule, these frames are relatively difficult to assemble and dismantle, as they are designed for a long stay in one place. To a large extent this also applies to more “flexible” wire (arc) frames. But sometimes, after the spring cold weather, it is advisable to quickly remove the frame or quickly re-install it in the same or new place. Such a removal of the frame is necessary, for example, for the convenience of loosening the soil, caring for plants during feeding, or simply because of the uselessness of their insulation. In this case, it would be useful to be able to adjust the height of the frame, and sometimes its width. In the fall, after harvesting, it is advisable to free the site from the frame, especially when treating the soil with any small-sized mechanical equipment. And to increase the longevity of the frame, it is useful to store it under a canopy or indoors during the “non-working” season (in late autumn, winter and early spring).

I have manufactured and tested (with a positive result) several options for wire frames that largely meet the requirements described above, that is, they are easy to carry, quickly install and disassemble, just adjustable in height, width and length.

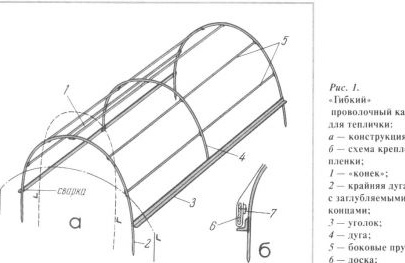

The first version of such a frame is shown in Fig. 1. Here, we weld three arcs of wire with a diameter of 6 mm to two steel corners with a length of 1200 mm (shelf width 40 mm). The total length of the middle arc is 3000 mm, the two extreme ones - 3500 mm each. The lower ends of the extreme arches with a length of 250 mm are buried in the ground to fix the frame in the desired position. On the inner side of the arcs are welded along the length of the skate frame - a wire with a diameter of 5 mm, as well as side wires with a diameter of 4 mm. It is clear that both the ridge and the side wires are necessary for laying film on them. By the way, fixing them from the inside of the frame creates less heterogeneity for the film and contributes to its better preservation.I cleaned the welding spots, rounded the ends of the wires.

Such a frame turned out to be easily straightened and bent, as well as stable and mechanically strong. At the same time, it has a small mass, can be easily removed, transferred and installed by one person, it can easily change its width or height. In fig. 1, and possible frame configurations are shown by dashed and dash-dotted lines (for the first arc). On a bed of normal width of 1200 mm, the height of the frame in the center is approximately 1200 mm. With the simultaneous overlap of two narrow beds with a total width of 2000 mm, the height of the frame in the center decreases to 300 mm. I have chosen a frame length of 1200 mm because the most commonly sold film has a width of 1400 mm.

To stretch the film, I used the “heaviness” of two boards with a thickness of 20 and a width of 120 mm, to which the film was nailed through a strip of linoleum with nails (Fig. 1, b). The mass of boards, as a rule, was enough to keep the film in tension. Sometimes, in windy weather, for insurance, it was laid on top of the film at the edges of the frame along one wire arc.

I made five of these frames, and in two of them I used the old 1-inch water pipes instead of corners. When sequentially placing several frames along a long bed, an "extra" piece of film about 100 mm wide was placed on the adjacent frame film and pressed with a spare wire arc. The ends of the frame covered with additional pieces of film.

Work on the site in 1996 showed the ease of use of such a composite frame. In early spring, using three frames, I closed two beds with a width of about 2000 mm for radishes, and the neighboring frames did not adjoin one another closely, but were spaced apart by 500 mm (I covered the gaps with additional pieces of film). Two other frames with the same “extension”, but with a frame width of about 2300 mm, allowed to protect flowering varietal strawberries from frost. Then all the frames were removed, the arches were bent to provide a greater height for the greenhouses, after which the frames 1200 mm wide were installed over the bed with tomatoes.

For caring for plants (hilling, top dressing, pinching, etc.), I remove this or that frame (usually together with the film). In warm summer weather, I reel the film onto boards, straighten the frames and store them under a canopy, where they take up very little space. In the period of autumn cooling, I put the frames again over the beds. My frames for greenhouses are made of the materials I had.

According to the stated principle, frames of a different length can be made. And no one forbids to use other profiles (pipe, channel, I-beam, etc.) instead of corners, and the wire for arcs is also suitable for a different diameter.

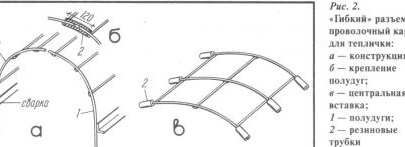

An even greater versatility of frames is achieved when they are made of two parts, that is, of two half arcs (Fig. 2, a). In this case, the optimal length of the half arcs is about 1300 mm. Half-arcs are connected in the upper part using pieces of rubber (dyuritic) tubes with a thread cord (Fig. 2.6). Such tubes are very durable, they are sold in hardware stores. With a half-arc wire diameter of 6 mm, tubes with a hole diameter of 4 ... 5 mm provide a rigid and reliable connection of the half-arcs. With a frame width of 1200 mm, the height of the arcs in the center above the ground is about 800 mm.

But the main advantage of this frame design is the ability to simply and easily increase its size, using the central insert shown in Fig. 2, c. The insert arcs are connected to the frame half arcs using rubber tubes as well. Having made, for example, two sets of inserts with different lengths of arcs, we get the opportunity to set the size of the greenhouse at our discretion. However, if the length of the insert arcs is too long, it is likely that an intermediate support will be needed for it.