The author took all the information for the construction of this all-terrain vehicle from the Internet. All terrain vehicle It was built for fishing trips no further than 20 kilometers, therefore it was made of a rather light construction. The all-terrain vehicle has four-wheel drive with a switchable rear axle.

Materials and assemblies used to build this model of an all-terrain vehicle:

1) Lifan internal combustion engine with a capacity of 15 hp

2) Four-speed gearbox from a classic vase

3) Transfer box from the car Niva

4) Fist swivel from Oise

5) T-150 wheels peeled

Let us consider in more detail the main components of the design of this all-terrain vehicle.

The fracture node was created from the knuckle according to the Uvat scheme.

Two profile B belts are installed, as well as a small pulley for 100 and a large pulley for 300:

Wheel disks were created from t-150 rims, which were wrapped in iron 2 mm thick, as well as welded along the perimeter. The fastening of the tire to the disk itself is done with the help of locking wheels, the beads that hold the tire are also welded from the inside. the tire itself is put on the disk with an interference fit, which gives even more fastening strength, plus the author used sealant. Is such a fastening enough to show the test.

A frame was made of a profile pipe by welding, as well as bridges from VAZ 2105 were installed on the frame, the gear ratio is 4.1:

Initially, the author wanted to make landing on the hub on his own, but it turned out quite difficult and unreliable, so I had to invest more in an all-terrain vehicle.

The weight of the all-terrain vehicle in the assembled state is 550 kilograms. The author also set about preparing an all-terrain vehicle for swimming.

Attachments to the half shafts were painted to immediately notice cracks if they did not pass the test. Although the design should not fail, since the washers are welded on both sides, this should be enough according to the calculations.

The steering was installed. The steering rack was taken from the VAZ 2110, but its travel is too small and this is not enough for convenient control of the all-terrain vehicle. Therefore, in the future, the author plans to either replace it or install an additional lever to correct the direction of movement, as well as increase the thrust.

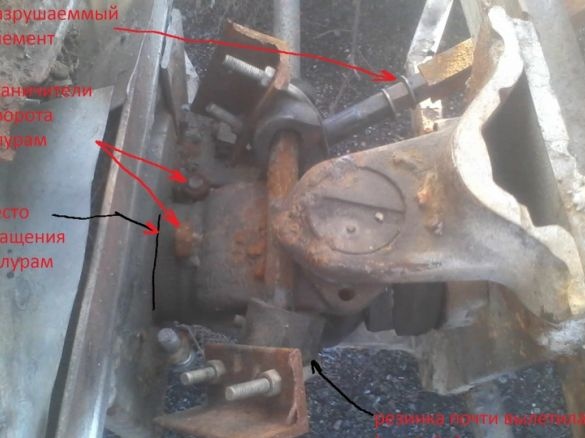

Then the fastening of the knuckle and the rear half-frame was done in this way:

To create a turning unit, a fist from an UAZ was used.

Further, the author considered two ways to create an all-terrain vehicle transmission.

Firstly, you can remove the transfer case and install the chain gear, then the speed will decrease, but the chains will become an additional vulnerability of the all-terrain vehicle, which will need to be worked on.

will have to shorten the frame, and make a more balanced weight distribution of the front of the frame.

Secondly, if you leave the transfer case, then you can simply replace the gears with cheap ones with a gear ratio of 4.3. In this case, we also get a decrease in speed, but not as significantly as we would like.

Regarding the weight distribution, it is possible to cut off the front axle and tuck the shank higher, so that it is almost possible to move the structure close to the transfer case, it is not entirely clear only about the oil level in the gearbox and how this will affect the operation of the system. It may also be worth disassembling the transfer case itself in order to reduce the number of downshifts, but this requires a serious approach to the study of technical documentation.

Also, to strengthen the turning unit, it is planned to install a couple of shock absorbers from the zil:

All-terrain vehicle was left in the sun outside the garage, the sun warmed the tires of the car and it spontaneously disassembled, which is rather unpleasant and speaks of the insufficient reliability of mounting the tires.

Urgent measures were taken to strengthen the fastening:

The steering rack was turned over, as well as a knot destructible under loads was added, after these actions it became much more convenient to steer.

Yes, the design is rather weak and not reliable, but for some time it will work and it will be possible to test the machine.

The clutch role of the all-terrain vehicle is performed by two belts. During a trip on an all-terrain vehicle, one of them flew for an unknown reason, the author decided not to put it back in the field, but simply remove it and drive to the garage on one belt. It was noticed that the all-terrain vehicle with one belt feels much better, there was a smooth ride, and most importantly it moves away without jerking.

Regarding the destructible structural element, it was made in this way: one bolt was removed, and the edge was twisted onto an aluminum wire, so that under loads it would simply bend the rods relative to each other. It is also quite convenient to adjust the load force by simply increasing or decreasing the number of turns of wire.

During the tests, the steering rod broke off, so this element also needs to be improved.

For example, installing the pump from the steering yamz 236,238, since it was immediately made for profile A, instead of nsh-10.

Silent means consent! I am really sure that installing data from (similar) units will greatly simplify your life. Instead, the NSh-10 is easier to use the pump from the steering YaMZ 236.238, it is immediately made under the belt profile A (if I'm not mistaken)

Photo nsh-10, weighing 2.5 kilograms:

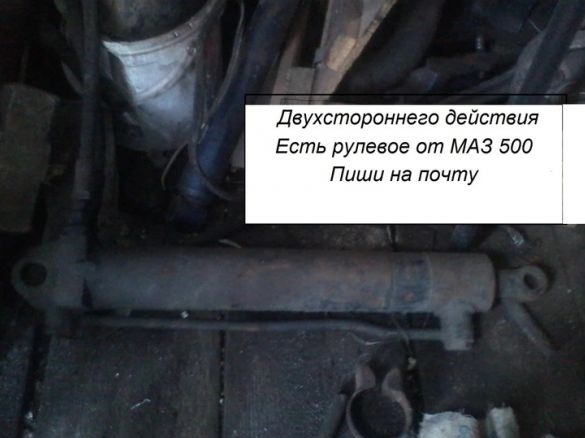

4 kg steering system:

Hydraulic cylinder weighing 5-7 kilograms:

It is also planned to install bridges on the springs to reduce shock loads on the transmission design itself, which will increase the speed and smoothness of the all-terrain vehicle. The hinge can be modified by replacing the knuckle with three bearings and a spacer, although the frame joint assembly can withstand the load and justifies itself.

But with the wheels there really are difficulties.

The wheels were very heavy, with a disc weighing about 85 kilograms. In addition, there is no central track - the all-terrain vehicle shakes. So in the future, the author plans to replace their other lighter ones.

The author also wants to remove the transfer case from the field and install a chain gear. There is another reason why the author wants to get rid of the transfer case, this is the speed of the all-terrain vehicle. In the first low gear, the all-terrain vehicle moves at a speed of about 5 kilometers per hour, and this is at idle of the engine.This is of course bearable, but for the minimum speed too much, too much load will go on the bridges and the engine itself when overcoming difficult obstacles.

Another of the design minuses is the author notes the weight distribution, most of the weight is directed to the rear axle.

ATV Test Video:

The author of the all-terrain vehicle: Ilya with the nickname "ardin" from the city of Velsk.