If you had a desire to put LED lamps instead of the standard incandescent lamps in the dimensions or rear signals of a car or motorcycle, then it is not at all necessary to buy them in the store and, moreover, it is not a fact that the LEDs of Factory China are caught and, as a result, their very short life , then spontaneous flashing will begin and soon they will completely go out. It’s a completely different matter if you make such bulbs yourself, using well-timed and personally tested LEDs from suitable donors, it can be indoor lamps, LED strips, stripes, etc. Such LEDs can work very long and brightly, and the number of elements in the donor is always large and enough to make any home-made lamps for all your needs car, and the price of the finished device will be scanty compared to the purchase.

For the manufacture of most automotive lamps, such a set will be sufficient:

1. LED lamp or strip or strip for 12-220v.

2. Radio amateur textolite (preferably double-sided).

3. A grinder or hacksaw for metal.

4. Accessories for soldering and a minimum of amateur radio tools.

Item 1. Preparation.

First we decide what, where and how much we need home-made lamps, for this we visit your car or motor vehicle, look and take out the necessary regular lamps. Now we study how the socles of these lamps look, at the same time we come up with what to make them from or you can even use these.

In my case, the base turned out to be glass, so it can’t be used, but you can repeat its shape and contacts very simply with the help of a conventional copper-plated textolite.

We also find at home or buy in the store a suitable multi-donor LED lamp, just be sure to look at what elements (cells) it consists of, usually these are rectangles of three diodes with a resistor, these elements are easy to dismantle and use for your own purposes. Each such cell is usually 12 volts, even in 220 volt lamps, only there is a power converter driver that we do not need.

Item 2. Production.

Using a grinder with a thin disk, I cut rectangles from the PCB to the size of the base I need, cut in the center to disconnect + from -. If the textolite is double-sided, then this is even a plus, but we just have to cut it on both sides, otherwise it will close and the fuse will fly out.

We remove the cells from the donor lamp, if there are no resistors in them, then it will be necessary to modify them and introduce a quenching resistor, usually it is several tens of Ohms, we select during installation ourselves, otherwise the LEDs will quickly burn out at 12 volts.

You can make bulbs of different light power, for this you only need to use more number of elements (cells) by soldering them in a circle, in my case there will be single and double.

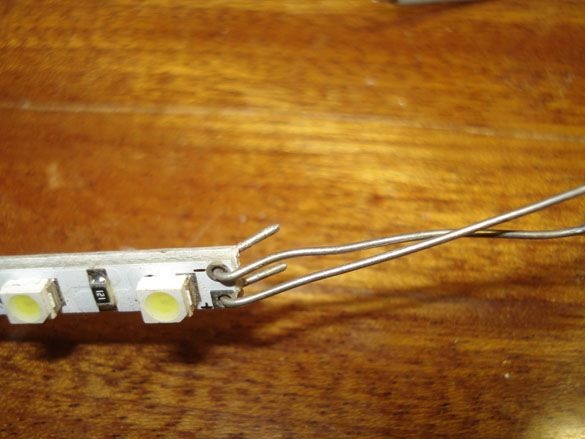

In the double version, we connect two cells as in the photo, make sure that + to plus - to minus. You can glue it on tape or just like soldering.

If the textolite is double-sided, then the polarity is not important, turning the bulb will fix everything, it’s completely different with one-sided and if there are only two contacts in the cartridge, then it is necessary to check the polarity and solder it correctly so that everything works the first time.

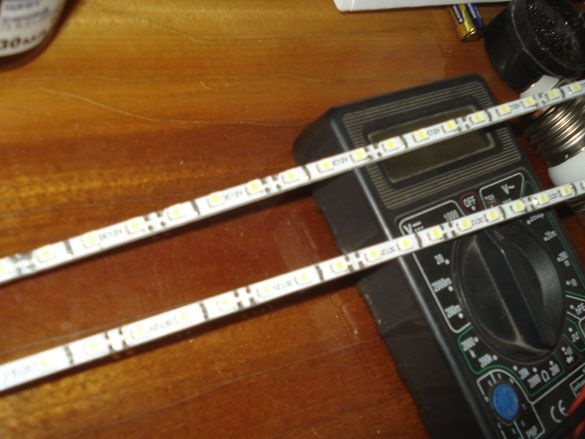

The LED strip option turned out to be even more convenient for manufacturing, we bite off segments of three diodes, along the edges there are already holes with contacts, there is a + and - designation, it remains only to correctly connect the polarity and insert the wires for soldering, it is convenient to use the legs from the resistors.

Solder the contacts to makeshift platforms (socles). You can additionally isolate everything with varnish, put on the required length of shrink cambric, but you can not do this, but rather run to check them in work.

Point 3. Test.

We insert the lamp into the cartridge, apply voltage, if it works, you can insert everything into the headlight, if not, then we change the polarity of the connection by turning the bulb 180 degrees around its axis.

As a result, the light of the dimensions was transformed and became visible even during the day, and therefore you can try to use it without necessarily turning on the dipped headlights in the daytime, which will give good gasoline savings.

Comparison of how it was, how it became.