The main task set by the author is to use wood sawdust as fuel. Finding them is quite simple and in most cases it does not even cost anything. But there is one caveat: in its natural form, sawdust smokes very much, burns poorly and emits little heat. To solve this problem, the author decided to make briquettes from sawdust, and paper will be used as a binder. How exactly to make such briquettes will be discussed below.

Materials and tools for manufacturing:

- sawdust (can be found at sawmills);

- paper (old books, newspapers, etc.);

- press;

- thick plywood;

- a plastic cylinder (a piece of sewer pipe is suitable);

- a trough or bucket for mixing the components;

- water;

- drill, hacksaw and other tools.

Manufacturing process:

Step one. We create a form for forming briquettes

First you need to find a plastic cylinder of suitable diameter, the author used a piece of sewer pipe for these purposes. Next, a drill is taken and rows of holes are drilled in the cylinder. They are needed in order for water to come out of the cylinder during the formation of briquettes.

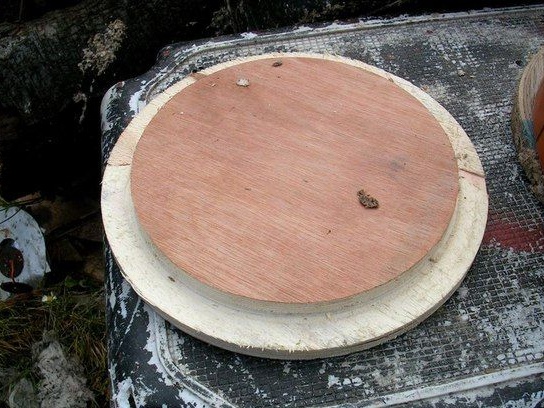

When the holes are drilled, you can begin to manufacture the upper and lower parts of the device. First of all, the bottom is made, it is made from a piece of thick plywood. As a result, the cylinder will have to be placed on the mold; no other mounting methods are provided. You can understand what the shape of the bottom of the cylinder should be from the photo.

As for the cylinder cover, it is also made of a thick piece of plywood. As a result, the cap should enter the cylinder, it will be a kind of piston that will compress the contents of the cylinder.

Step Two Create a mixture

Now you need to create a mixture from which briquettes will be formed. You need to take the paper and dissolve it in water to make a porridge. In cold water, the paper dissolves for about 30 minutes, in hot 5-10 minutes. Next, in this paper pulp, you need to add sawdust in the calculation that one part of the paper has two parts of sawdust.All porridge formed should be thoroughly mixed.

Step Three Formation of fuel briquettes

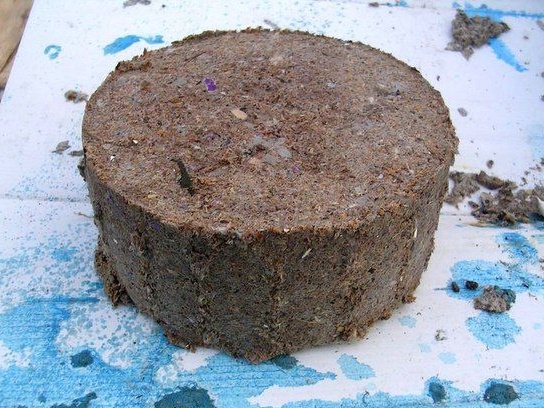

Now you need to take the cylinder and set it to the bottom. Then you can start pouring the mixture. Pour under the neck. Subsequently, the cylinder is covered from above with a lid and placed under the press. After the water is displaced, the finished briquettes can be removed from the cylinder.

That's all, now it remains only to lay out the finished briquettes in the sun or in the barn so that they dry. It takes about three days to dry completely. After the briquettes have dried, they can be folded, thereby preparing for the heating season.

If there is a sawmill nearby homemade will be an excellent find on the farm.