Interesting all-terrain vehicle with numerous construction features. The author made the design of the frame with a fracture assembly, precisely so that the all-terrain vehicle could be easily disassembled for transportation in the van, so all the basic structural elements can be easily disassembled. The design of the all-terrain vehicle wheels is also interesting, where instead of tires, the cameras are protected by fabric casing, which gives the all-terrain vehicle a very unusual look.

Materials and assemblies used to create this all-terrain vehicle:

1) Engine Lifan-168f-2r

2) gearbox from gas-51

3) hubs and drive shafts

4) front steering knuckle from vaz 2101

5) steering system from vaz 2108

6) 15 inch wheels

7) pvc fabric

8) gearbox from zaz

9) CF cameras

Consider in more detail the design and main components of the all-terrain vehicle.

The frame was cooked from a profile pipe:

An lifane engine was installed on the all-terrain vehicle. Then, a gearbox with hubs and drive shafts was installed, from which a prom was made. half frame shaft. The fracture knot is made of a knuckle from vases 2101 with a hub and ball.

An all-terrain vehicle control system was installed, consisting of a steering from a vaz 2108, which is being transmitted from the steering column using a flexible shaft.

The 15-inch wheels were specially expanded to 30 centimeters to put 1070 by 400 wheels on them.

The front wheels are made with landing on the ZAZ bridges, and the rear ones under the hub from the VAZ 2108. The bus tires themselves are made of pvc fabric with landing on the disk. Hold pretty tight, which does not allow turns.

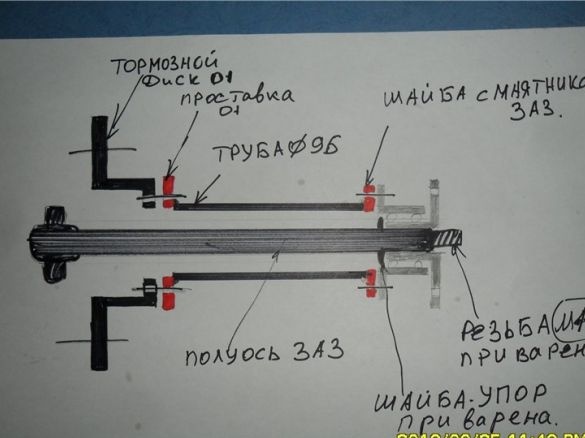

The density of the material for tires is 1.4 kg per square meter, they are also reinforced with two layers of sidewalls with a density of 850 grams per meter. The cameras are used from KF wheels. A semi-axis from the zaz is installed, where a threaded rod is welded to the spline, and a ring is made in front of the splines to abut the bearing. A brake disc from vases 2101 was installed on six studs of the box, welded to a pipe with a diameter of 96 mm through a steel thrust washer of the front hub.

On the other side of the pipe there is also a steel washer to which the ZAZ hub is screwed off from the lever.

The body of the all-terrain vehicle itself is made collapsible, it takes about half an hour to completely disassemble. When disassembled, it is placed in a small van, which greatly facilitates the transportation of the all-terrain vehicle.

The all-terrain vehicle has the following dimensions: length 2 meters 80 centimeters, width 145 centimeters and a height of 140 centimeters.

To increase traction, as well as water speed, fangs from the halt were attached to the tires.They were glued directly to PVC fabric for hot glue with rolled products.

Transmission from the gearbox goes through the chain to the prom. all-terrain vehicle shaft.

In more detail about the design of the half shafts:

Here is the initial version of the all-terrain vehicle:

The all-terrain vehicle has a very low weight of about 200 kilograms, so the buoyancy on the water is excellent. when traveling on heavy off-road, especially on uneven surfaces, heavy loads are put on arms and legs, therefore, in the future, the author plans to establish a depreciation system and accordingly put more wheels.

The minimum speed of the all-terrain vehicle in the first gear is five kilometers per hour, and in the fourth maximum 23 kilometers per hour.

The all-terrain vehicle uses a chain transmission. from the engine, the chain in increments of 12.7 goes through the prom. the shaft to the gearbox from Zaz. The ud-2 clutch with the gearbox from gas 51 was docked through the plate, the clutch was also used from gas-51. The steering rack is mounted back to the side, since it is technically impossible to install it technically due to the peculiarities of the arrangement of all-terrain vehicle structures.

The differential in the gearbox is not locked, as this is not required. The engine has a power of 6.5 hp. which is enough due to the low mass of the all-terrain vehicle. In the transmission, a triple reduction was used: the gearbox was 1 to 2, from the gearbox to industrial. the shaft is 1 to 3, and from the shaft 1 to 2.07 to the input shaft.

Photos of the off-road vehicle:

The author of an all-terrain vehicle with the nickname "pike" on the Lunokhod website.