All terrain vehicle has a tipping frame, as well as four-wheel drive. The all-terrain vehicle is made by a fairly simple and standard design. During its construction, the author tried to use the highest quality parts to ensure reliability.

Although this still did not help to avoid some of the disadvantages that proved to be during the tests. You can read more about them and how the author eliminated them in this article.

The materials and assemblies involved in the creation of this all-terrain vehicle:

1) bridges from the car Moskvich

2) the steering knuckle from Oise

3) pomegranate from the cornfield

4) Trackol wheels

5) Engine two-cylinder Lifan 2V78F

6) gearbox from an oka car

7) rail from vaz 2141

8) CVT Safari

9) gas tank from vaz 2126

10) steering wheel from vaz 2126

Let us consider in more detail the main components of the structures and assembly steps of the all-terrain vehicle.

A few photos of all-terrain vehicle designs:

The differential in the gearbox has been pre-welded before installation.

The all-terrain vehicle has a double seat, and it is also planned to install a windshield and a roof in the future. On the back of the frame, it is planned to make a kung with seats.

The gas tank was installed too far and the native pump did not provide the necessary performance, so the author, in order not to change the design of the arrangement of parts in the all-terrain vehicle, decided to replace the pump with a more powerful one. A German low-pressure electric pump was installed. After installing it, the problem was resolved.

Tires from Trekol were stripped and lightened before installing on an all-terrain vehicle.

The backstage was installed as follows: the author put on a stock a thick-walled sleeve, the wall of which is about 6 mm. then two holes were drilled under the M8 bolts for fixation. flats were made on the stem for clamping these bolts, and two nuts are welded to the sleeve one on the other with a thread, as on the tip of the rod. The tip is screwed on them accordingly.

The tips are interconnected by a rod, which passes through the plate with the hole. One of the tips is wrapped in a welded nut to the gear lever from a classic vase.

In first gear, the all-terrain vehicle goes at a speed of 1-2 kilometers per hour, and moves off in any gear to any hill. Traction is very good in an all-terrain vehicle.

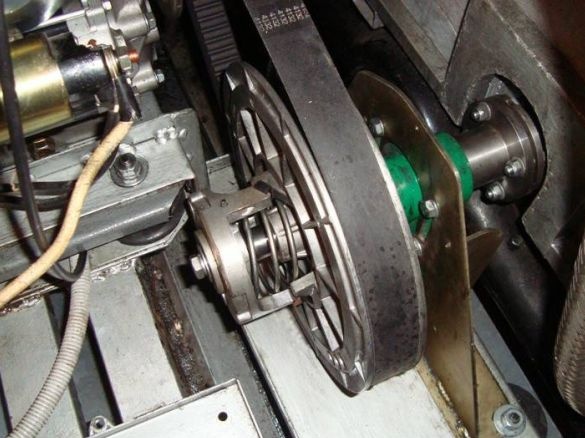

And here you can see the mount of the all-terrain vehicle driven to the frame. the bracket is located on the frame, and the follower is attached to it and is attached. Below the bridge it is clearly visible:

Below is a photo with the battery removed, as you can see the replacement of the strap is quite easy, in any case, until the casing is installed on the belt:

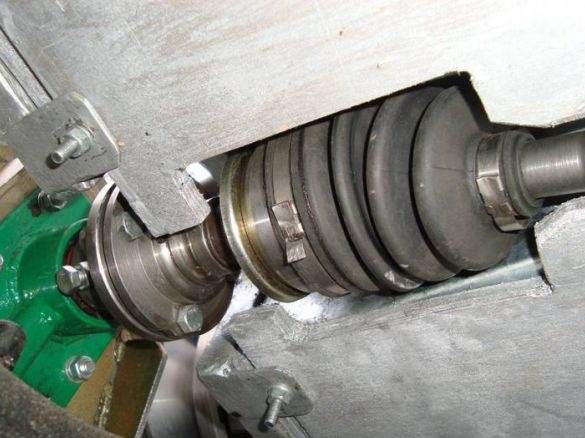

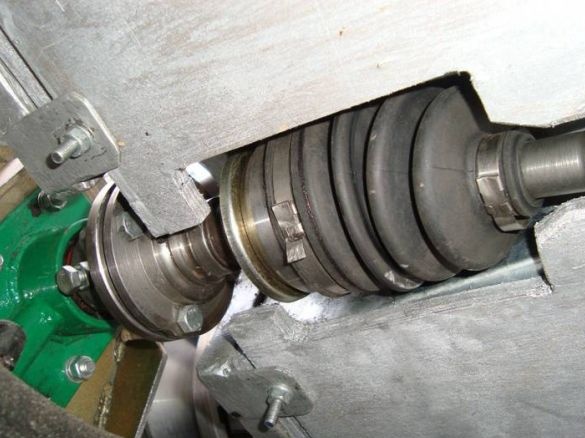

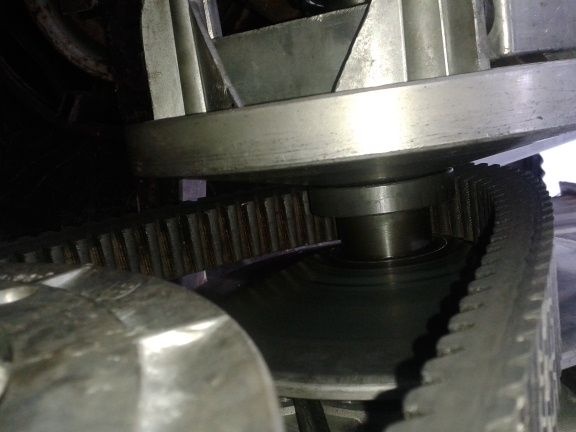

From the slave, the transmission goes to the flange drive, and from the flange to the machined hub and grenade from the Oka car:

And in this photo you can see the mount to the gearbox:

Flanges were installed on both sides. one of which is dressed on the shaft of the driven disc of the variator, and the other on the gearbox shaft. A sleeve with splines from the Oka clutch disc is pressed and welded inside. in order to dress on the shaft. Fixing flanges is provided with bolts. hubs from oki with drilled holes for fastening to flanges are attached to them on four bolts. The whole structure is interconnected by a short shaft and native grenades from oki. The grenade of the variator is screwed with a standard nut to the hub, and the second grenade is not fixed, which allows it to move freely on the splines.

Regarding the minuses of the all-terrain vehicle: if you go in a straight line on 2/3 of the gas, then after a while the engine starts to work strangely, it is noticeable only in winter, it pulls worse, the speed drops by itself, that is, it works intermittently.

During the inspection of the systems, it was found that a piece of ice was in the carburetor nozzle. Therefore, the author decided to make heating by redirecting warm air from the muffler. In summer, naturally, this heating should be easily dismantled as unnecessary. To create heating, 0.8 mm thick galvanization and a flange on the stainless steel carburetor pipe were used.

The result was a tunnel, which is located right next to the silencer. It will be installed in the place of the filter, since in winter there is no dust and it is not particularly needed.

And as it gets warmer, that is, in spring or summer, this engine heating system will be dismantled, and the filter will be installed in its place again.

Another of the minuses of the all-terrain vehicle design was the vibration of the drive going from the variator to the box, it starts to vibrate at engine speeds above average values. In order not to overload the design, the author decided to balance this scheme.

Below is a photograph of this unit: a stick and grenades from oki on both sides plus turned chiseled flanges.

This part has a common large console. At its loads, there is a high probability of damage to the front bearing of the gearbox, which in turn can bring even more significant damage. In order to avoid this, it was decided to bring the CV joint closer to the front bearing of the gearbox as close as possible. Unfortunately, this will not give full confidence in the safety of this connection, but at least reduce or completely remove vibration. In the future, it will be possible to install a bearing with a bearing on a machined hub oki.

Since for such a solution it was necessary to disassemble the main drive, the author at the same time made an upgrade in the all-terrain vehicle engine, in order not to remove the engine speed regulator, and use it in the summer along forest roads and wetlands, otherwise the gas cable directed directly to the carburetor does not inspire reliability. It was decided to increase the turnover by reducing the weights. The front cover was removed and the regulator gear removed.

There are three legs on it, which press on the central peg, and through the lever it covers the gas damper. Therefore, it was decided to undermine it a little.

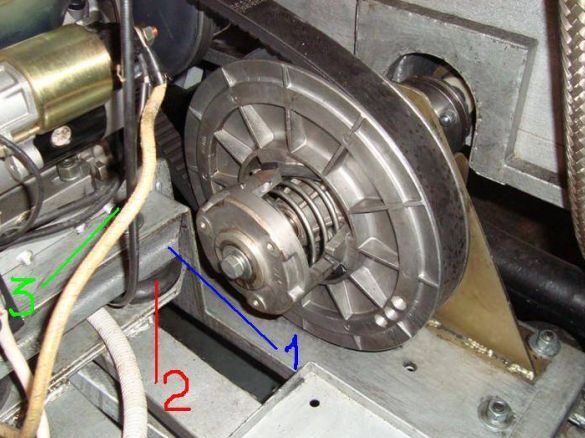

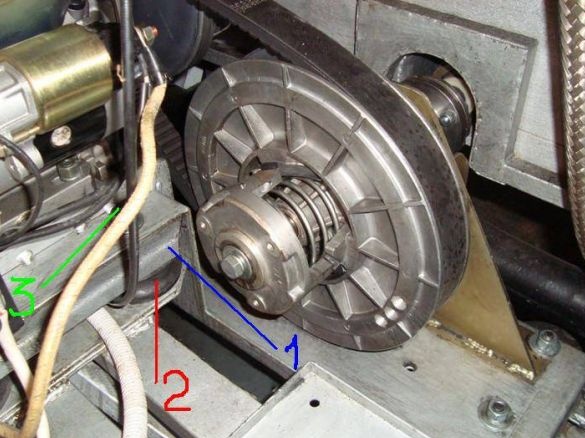

Here you can see in more detail the mounting of the engine and the entire system as a whole:

In the photograph, number one is the plate under the entire engine, which is mounted on it through standard holes on the bottom of the crankcase.

At number two, there are four mount pillows that were taken from a classic vase.

Number three is the nut that secures the engine plate to this pillow.

A few more photos of the design of the all-terrain vehicle:

From above, the bracket is still visible, which connects the engine and variator mount in a single mechanism. This is necessary because the engine under load can move on the pillows, and the mounts for the variator and the engine are respectively separate initially. Although it is better of course that both the engine and the variator stand on the same bracket, which the author tried to organize with a similar fastening scheme.

Photos of the off-road vehicle:

ATV Test Video:

The author of an all-terrain vehicle with the nickname "Yuryevich" on moonwalkers. Is not from the Sverdlovsk region.