The all-terrain vehicle made by the author for fishing trips and picking berries. This means that in addition to excellent cross-country ability on forest roads, the all-terrain vehicle also had to be able to overcome marshy terrain and other water barriers. How exactly the author achieved the required results, you can learn from this article.

Materials and assemblies used to build this all-terrain vehicle:

1) cameras from k-700

2) internal combustion engine from an oka car

3) gearbox from the car Oka

4) bridges about vaz 2101

5) TOYOTA steering and hydraulic pump

6) conveyor belt and belt type D

7) profile pipe 40 by 35 with a thickness of 2 mm and 25 by 25 with a thickness of 1.5 mm.

8) the upper ball from the vaz 2101

9) chain step 19.05

10) pipe 1 \ 2 "

Let us consider in more detail the main components of the structures and the stages of construction of the all-terrain vehicle.

To begin with, the author decided to make the frame of the future all-terrain vehicle, taking for this a profile pipe measuring 25 by 25 and 40 by 25.

The frame fracture assembly was made according to the author’s home-made design using the upper ball from vases 2101:

In order to avoid excessive efforts on the ball, their stroke is limited to ordinary chains.

The author cannot say exactly what kind of load the fracture node has, but it is probably standard for these ball joints, namely the upper arm of the front suspension of the VAZ 2101.

A rather significant place is occupied by the distribution of weight among the half-frames of the all-terrain vehicle. That is, the balance must be maintained so that the weight of one frame is not transferred to the second through the frame fracture assembly, thereby loading it even more.

In this all-terrain vehicle, the weight of the engine is balanced by the weight of the driver. But in essence, this node is an experiment and it takes time to make sure that it is reliable or to find vulnerabilities.

By the way, the all-terrain engine itself:

Closed-type bearings No. 6208 in the amount of six pieces were installed in the hubs.

Such a number of bearings was used for simplicity and reliability of the design, in particular for that. so as not to deal with bushings.

The wheel diameter in the end turned out to be 1600 mm, and the width was 700 mm.

Then the author proceeded to install the steering:

Due to the fact that the gearshift scheme was turned upside down by 180 degrees, it was difficult for the author to switch gears at first, but perhaps everything was faced with such difficulties during the first control of this all-terrain vehicle, after getting used to it, there were no problems with gear shifting.

Also on the all-terrain vehicle there is a compressor for pumping tires.

Sheathing of the all-terrain vehicle is planned from plywood sheet, although carbonate was supposed to be used at first, but it is not known how it will behave in the cold during vibrations.

SHRUS and a nave with a brake were used by relatives. the differential was made as follows: one satellite gear was taken, and the remaining 3 were removed. Then the grinder gear was given the shape of a square, for that. to install it in a square hole plate. The satellite itself was installed in place, from above this plate was bolted to the differential housing, in the place where the driven gear of the bridge is located. After that, a constant velocity joint was installed and a satellite with platinum was welded.

Not to say that the design turned out to be super reliable, so the author always carries with him a spare CV joint.

Then the author made a frame for sheathing:

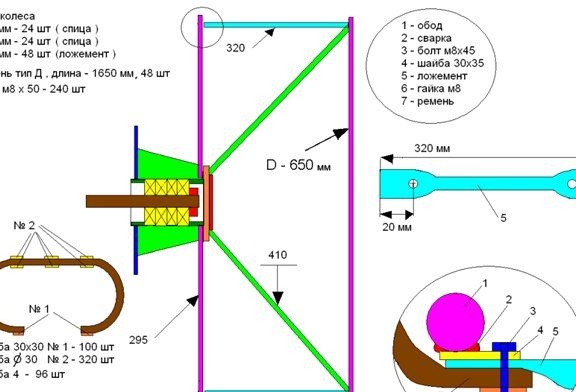

On this diagram, you can learn more about the design of all-terrain vehicle disks, their sizes are also indicated there:

But the tires that are attached to the discs using belts:

And here you can see the gearshift mechanism:

A special conductor was made from a disk from the t-150, a 1 \ 2 "pipe was bent on it. After that, the hub was welded to the sprocket. A hub and rim were mounted on the conductor, after which the spokes were welded on one side of the wheel. Then the wheel was turned over and the second rim was put on. and the remaining knitting needles were boiled.After these works, square washers were welded, which serve as the fastening of the lodgements.

The project has some pretty tangible design minuses. Since the steering consists of a hydraulic distributor and two hydraulic cylinders, then the all-terrain vehicle runs on virgin soil, but on the road the control is rather complicated.

The weight of the all-terrain vehicle was about 700 kilograms. maximum speed is 35 kilometers per hour. The all-terrain vehicle has the following parameters: length 460 centimeters, width 260 centimeters, height 220 centimeters.

Video with the off-road vehicle ready:

The author of the all-terrain vehicle: Dmitry from the Irkutsk region with the nickname "Professor" on the website.