Initially, the author planned to make light karkat, but after looking at the necessary efforts and costs, he decided that creating a larger all-terrain vehicle with the design of a tipping frame would not be much more expensive both in terms of labor and resources. Therefore, it was made like this all-terrain vehicle with a cabin and a kung, which is great for trips to difficult places and has sufficient carrying capacity and capacity to carry all kinds of cargo.

Materials parts and assemblies used by the author in the construction of this all-terrain vehicle:

1) Engine CWD with water cooling, head PD-10.

2) Temperature and charge sensors, cigarette lighter, headlights.

3) Gazelle pump

4) a fan with electronic and manual activation.

5) manual gearbox from the Niva

6) electric starter

7) electric winch

8) prom. shafts from the cornfield

9) the steering knuckle from Oise

10) wheels from KrAZ 1300 to 530 to 533 four-layer

11) gasoline vacuum pump

12) a plastic gas tank from an outboard motor of 10 liters

13) vacuum transmission brake

14) caliper from the car oka

15) a hydraulic cylinder from a UAZ car

16) szd reducer

17) transfer box from the cornfield

18) bridges from vases

19) profile pipe

Consider in more detail the basic design of the all-terrain vehicle, as well as the stages of its construction.

To begin with, the author made an all-terrain vehicle frame. The frame was welded from a profile pipe. The length of the frame was originally 1400 mm, as it was made for a light all-terrain vehicle without a transfer case. As a result, the author still did not find a way to do without a transfer case, so most units are placed very compactly, but still the frame will likely have to be increased by 10-15 centimeters.

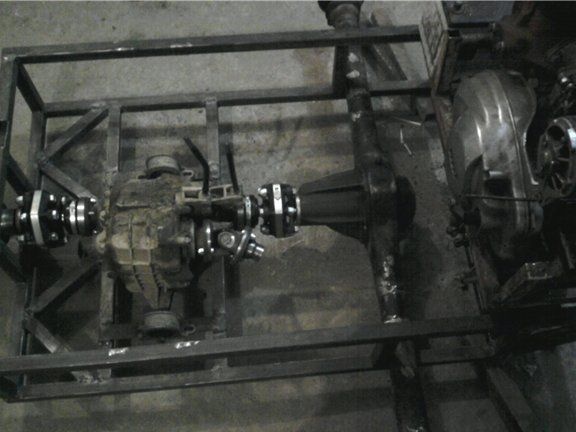

Bridges from vases with gear ratios 4.1 and final drive 41 to 10 were installed on the frame.

The distance from the attachment of the axle floor to the all-terrain vehicle frame is 230 mm, the drive is 15-18 degrees from the center of the hub to the frame, and the dimensions of the camera are 1300 by 530 by 533 mm.

Although the author also considers in the future to use ragged rubber from bast shoes on an all-terrain vehicle. That is why the disks were made immediately with a removable ring under the rags and belts from the conveyor belt will be attached to it when traveling on chamber rubber.

Here is a winch used to strip tires:

To strengthen the nodes were bought prom. shafts. The author does not want to make a long outreach because of the possible vulnerability of such a design.

Then a radiator with liquid was installed, a steering gear from an UAZ car, a thrust to the steering knuckle, which is the basis of the all-terrain vehicle turning unit, and the driver's seat.

Shank that goes to the manual gearbox from the cornfield:

It rotates clockwise, as does the lead.

The gearbox of the bridge was turned upside down:

A clutch master cylinder from an UAZ vehicle was also installed. after which the author took up the brakes. To do this, a brake hose was taken from a classic vase and connected with a makeshift adapter to a hose from an automobile. used handbrake lever from the vase. The brake disc was used with a homemade design with a thickness of 8 mm and a diameter of 200 mm. Complementing the design, a support from Oka was installed.

Here is the steering wheel of the machine:

Other photos of all-terrain vehicle nodes:

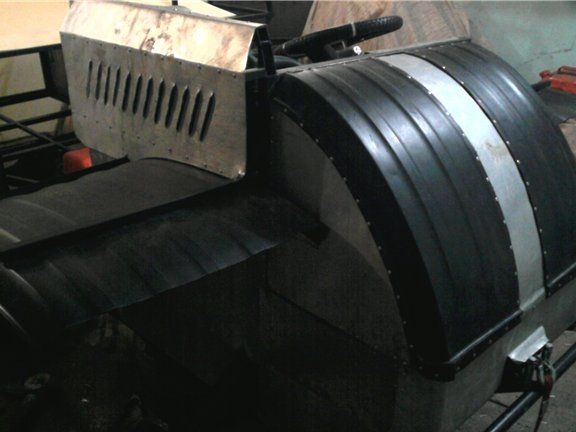

Then the author proceeded to cover the all-terrain vehicle. the wings and hood of the car were made, the radiator protection was made from the remnants.

After completing the sheathing of the machine, the author proceeded to paint work.

Comparative dimensions of the all-terrain vehicle:

The author of the all-terrain vehicle: Anatoly from Khmao-Yugra, p. Priobye with the nickname "Priob70" on the Lunokhod website.