With the onset of cold weather, many are faced with a situation when it is necessary to heat a room, but, for various reasons, this cannot be done using centralized or gas heating. An excellent solution to this problem is to use a potbelly stove for heating. Don't you have a potbelly stove? It does not matter, anyone who possesses the necessary tools and, most importantly, desire can do it.

The first is what to make of it? When choosing a metal for a future stove, and, importantly, its thickness, remember the following: a too thick sheet of metal, namely 7-8 or more mm, will warm up for a long time, which means that most of the heat generated during the combustion of firewood will not go to heating the house, while heating the metal. There is a reverse practice: too thin metal will quickly collapse and deform under the influence of high temperature, which means it is also unsuitable for use in the manufacture of potbelly stoves.

The best choice for our stove is metal about 4 mm thick, which is optimal for creating a potbelly stove.

To make a simple and reliable potbelly stove we need:

- a drawing with previously thought-out dimensions of the stove itself;

- a sheet of metal, the dimensions of which must correspond to the dimensions of the future potbelly stove;

- steel corners;

- several metal pipes of different diameters;

welding machine;

- an improvised tool, such as pliers, a vice and other.

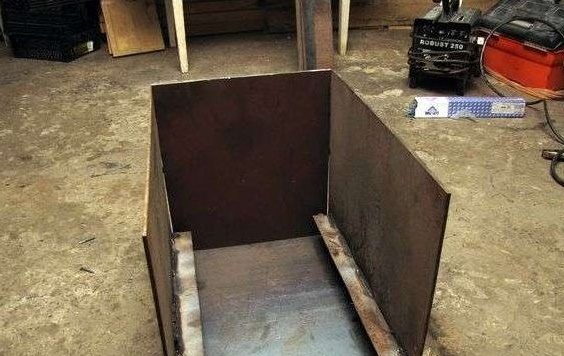

The main part of the potbelly stove, namely its body, will be made in the form of a kind of rectangular box. For this, it is necessary to prepare its main planes in advance: two side walls, a bottom, an upper and a back.

Why is there no front end? The fact is that it is the front door of the potbelly stove and the blower that will be located, so we will deal with the front part separately a little later.

We start from the side walls. We weld them to the bottom of the future potbelly stove at an angle of 90 degrees, helping ourselves with a square or level. Having previously outlined their location relative to the bottom, we grab them by welding; After checking the correct location of the walls, we weld them. Next, we weld the back of the stove and proceed to the internal arrangement of the potbelly stove.

From the inside, our potbelly stove can be schematically divided into three parts: smoke, firebox and ash pan.

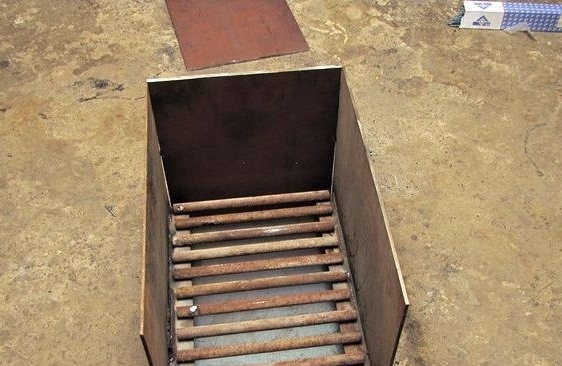

We start with the arrangement of the ash pan. To do this, from the inside of the stove on its side walls, we weld corners at the entire length of the walls at a height of about 10-15 centimeters from the bottom. Next, proceed to the manufacture of the lattice.

The grill is made of two metal rods and metal strips welded onto them, with a width of about 3 centimeters, with a welding step of about 5 centimeters. The length of each strip should be equal to the width of our stove in order to be located inside from wall to wall.

Pay attention to the fact that you do not need to weld the grate to the stove, it should be easily removable, so that in the future there will be no problems with cleaning the stove from ash.

Having finished with the grill, we proceed to install the reflector. To do this, weld two parallel metal rods inside the potbelly stove on its side walls, in its upper part. Having finished with the rods, we install a reflector on them. Pay attention to the fact that it is the reflector that will heat up more than other parts of the potbelly stove, therefore it is necessary to make it from thick metal, with a thickness of about one and a half centimeters. We, as well as the grill, make the reflector removable for comfortable and easy cleaning of the stove in the future.

Now we proceed to the final stage - we weld the top of the potbelly stove, with the hole for the chimney made in advance. Having welded the “roof” of the stove, we proceed to its front part. We weld the upper jumper, and the jumper separating the doors of the ash pan and the furnace itself. The reference point for the second lintel is the grate, separating the ash pan and the furnace. As for the dimensions of such doors, the main thing is your convenience. Doors are necessary so that it is convenient for you to lay firewood in the furnace and clean the ash from its bottom. In addition, a grille and a reflector must pass through the door if you suddenly need to get them.

Having finished collecting the potbelly stove, it is necessary to install it on the legs of metal, which can be made from an ordinary metal tube or a metal corner welded on the sides of the potbelly stove.

Having put the potbelly stove on its legs, we weld a chimney made of a pipe with a diameter of about 15 centimeters, and enjoy the heat from our potbelly stove.

Now you are not afraid of any frosts!