All terrain vehicle It has four-wheel drive and is built on a frame of a tipping type construction. This all-terrain vehicle is able not only to overcome any soil, but also excellently crosses rivers and small ponds. The swimming ability due to the sealed discs is quite high. The machine is capable of transporting up to 500 kilograms of cargo, taking on board a few passengers and without breaking.

Materials and parts used to create the all-terrain vehicle:

1) Tiger-390E internal combustion engine rated at 13 hp

2) starter

3) five-speed gearbox Golf-2

4) clutch and CV joints also from Golf

5) bridges from a classic vase

6) metal profile

Consider in more detail the stages of construction and the main nodes of the all-terrain vehicle.

The frame of the all-terrain vehicle was welded by the author independently from the profile pipe.

The bridges were reinforced and slightly modernized, a preload of 1-3 kilograms was made. Also, brakes were installed on the all-terrain vehicle, but only on the front axle, and the handbrake is made separately for each wheel.

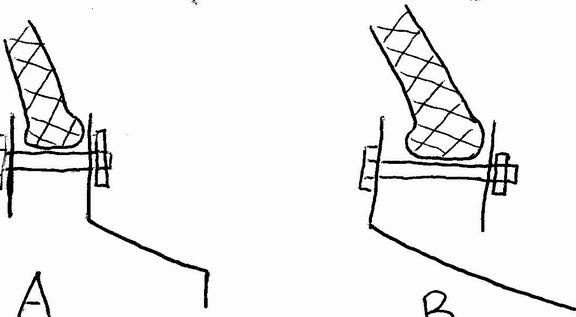

In this photo you can see how the preload to the bridge is made:

The valve spring presses on a pair of secondary bushings that inhibit the satellites. Another sleeve was mounted on the shank between the tapered bearings. After such upgrades, the bridges of the all-terrain vehicle began to rotate perfectly.

The four-stroke single-cylinder Tiger-390E engine was bolted to the frame through the pillows of the Volga car.

Work has also begun on the rear axle of the all-terrain vehicle

the stick was shortened:

Improvements to the front axle of an all-terrain vehicle.

But the spare parts used to lock the differential:

Also, the author had to make a third fulcrum under the clutch shaft bearings, otherwise there was a flywheel deflection, since only two points lacked rigidity:

After the main work on the transmission of an all-terrain vehicle, the author began to manufacture wheels. The wheels were lightly torn, but the landing was not touched and the wire did not reach. As you can see, the tread is cut by a Christmas tree with a flange.

At the same time, the author made a silencer for his all-terrain vehicle.The length of the silencer is 400 mm, the diameter is 10.5 centimeters. to give rigidity to the last can, the author made an ellipse. the first and second banks are made thick-walled.

The tire stripping technology was as follows: cut to the next fang, in order to be able to catch on. Undercut in the place where the inner cord.

Layers stretched with a winch. but they were cut with an ordinary clerical knife:

The layer is cut to the flanges, then the winch is weakened, the canine is tilted and cut.

Before starting peeling, the author started the camera, and fixed the wheel with a chain, so that it was convenient to turn the wheel. To turn on the winch, the pedal from the sewing machine was used.

A K65C carburetor was installed. After which the engine speed increased to 5 thousand. The carburetor is pretty easy to adjust, and works great. the author also plans to install the filter.

The wheels for the wheels were made airtight, since the all-terrain vehicle would have to keep afloat well.

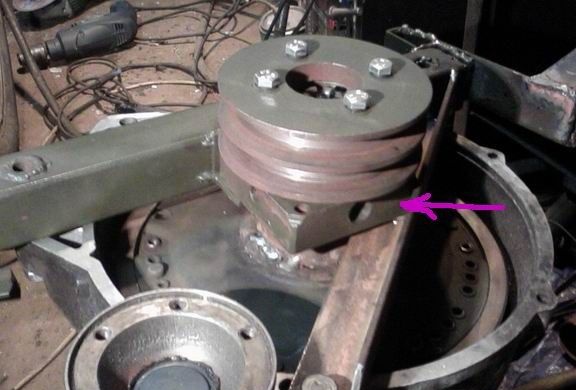

Below is a diagram on which disks with the main dimensions were made:

a barrel of 50 cm with a thickness of 1.5 mm was used, the end of 45 degrees with a thickness of 2 mm, and the disk from a classic 13-inch vase was taken as the basis. The disk is mounted on a standard 6 m6 nuts. There are also two locking rings.

The weight of the disk assembly is 22 kilograms.

The camera weighs 15 kilograms. peeled tire from vi-3 single-beam with four layers. the width of the lugs is about 3 centimeters, weighs 36 kilograms. The wheel assembly weighs about 73 kilograms.

This is how the locking ring is made:

A vulcanizer was also made.

After installing the wheels on an all-terrain vehicle, the author proceeded to test the car. The machine was tested not only on land, but also on water. The engine copes and there is enough power. The all-terrain vehicle feels great on the water. However, when traveling ashore, for some reason, the center lock did not work. it was very difficult to go ashore without her. After it was still turned on, the all-terrain vehicle easily coped with the obstacle. In the first and second gears any conditions of the route are easily passed. the maximum speed of the all-terrain vehicle in fifth gear on a flat surface is 35 kilometers per hour.

Work was done on the rear frame, in particular, it was strengthened in the bridge mounts.

And then captured the moment of departure to land:

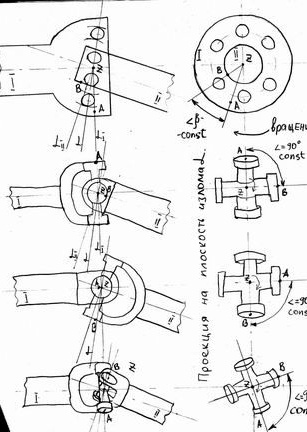

Regarding the steering of an all-terrain vehicle:

Rear frame:

In order to figure out why the differential lock did not turn on, the author decided to disassemble the box and carry out its maintenance:

After that, the author decided to upgrade the system, three teeth were cut on the differential case and flange. The flange was pierced under the gland. The shaft was shortened and honed. due to the fact that there are 3 teeth on the flange, it is easy to process them so that the edges intersect in the center, and they will not be twisted and bent, that is, the design will be more durable:

A 14V 65A generator was installed:

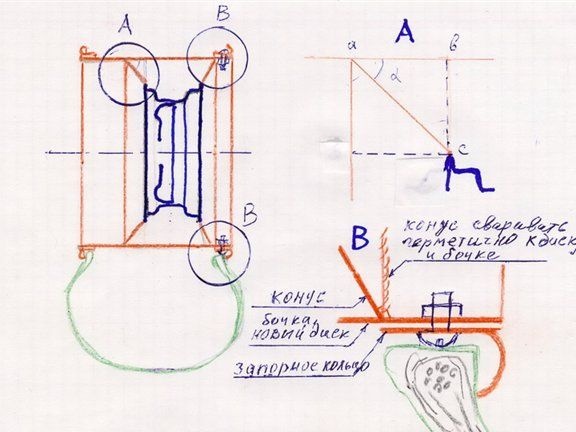

All-terrain vehicle sheathing work has begun:

In more detail about design of interaxal blocking:

The all-terrain vehicle is actively operated. even with a strong overload of up to 620 kilograms, the all-terrain vehicle regularly carries weight and overcomes obstacles.

ATV Test Video:

ATV photos:

The author of the all-terrain vehicle with the nickname "Vovan Ya" on the site of the from the city of Stolin Belarus.