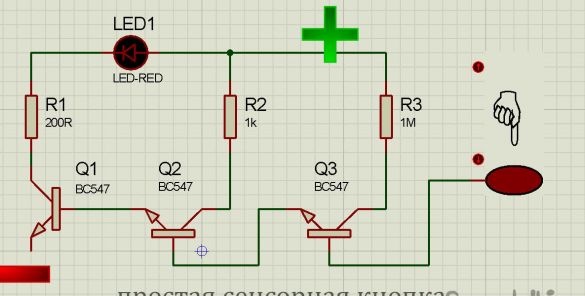

The simplest touch device can be assembled on several available parts. Only three transistors, three resistors and one LED, that's all. You can even assemble the circuit by hanging installation, everything will work.

Transistors are any NPN structures: KT315, KT3102 or BC547 or any other. Resistors 0.125-0.25 watts. The LED is of any color, but red is better, since the voltage drop is minimal. Power 5 volts, more less is possible and less too.

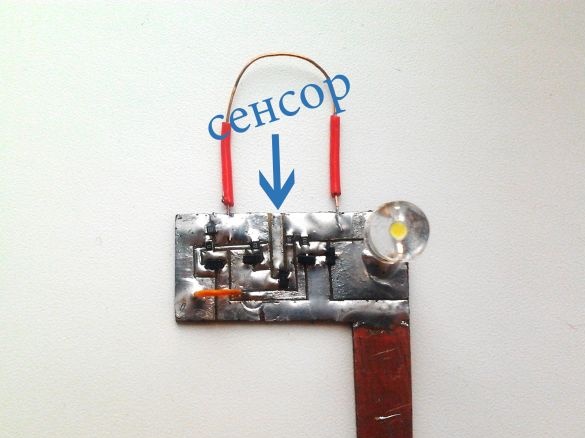

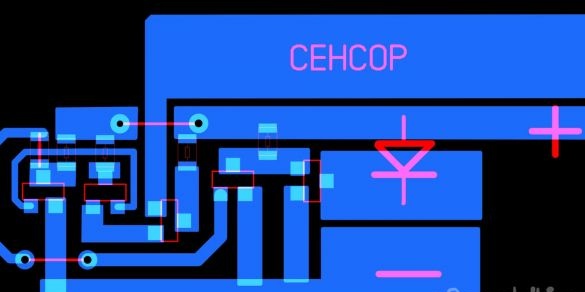

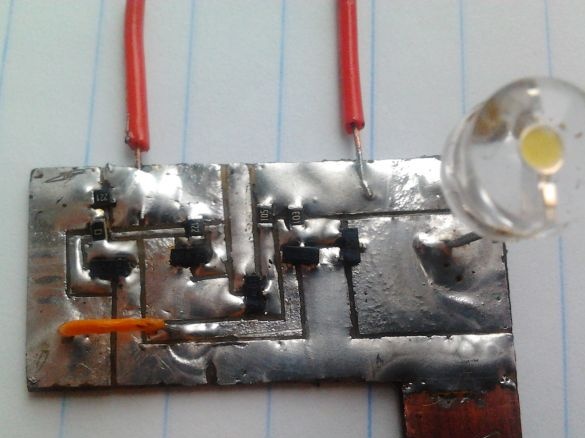

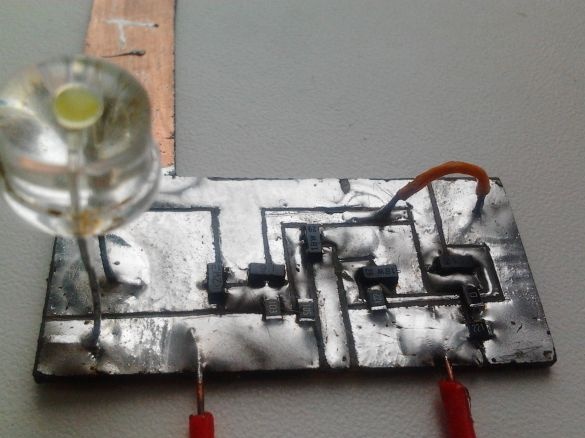

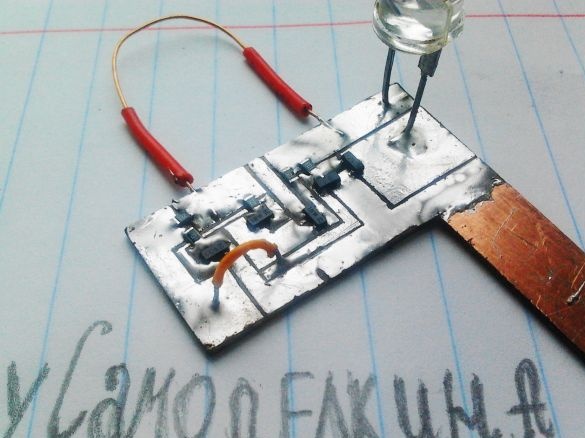

All components were compactly interconnected on a miniature printed circuit board, which can be done simply by cutting out the excess copper with a torch, leaving sharp polygons in this way. Parts used for surface mounting, transistors in sot-26 npn, resistors 0805, jumpers - pieces of wire, instead of them, if you take a large 2512 resistors with zero (conditionally) resistance. The touch device works immediately, without configuration.

Explanation of the operation of the circuit

Touching the base of transistor Q3, you open it with tips, as a result of which a current flows through its CE and 1 MΩ resistor, which opens the next semiconductor Q2, opening it opens Q3, which already controls the LED, opening through its CE flows current, from the minus goes to the cathode LED, and it is already connected to the anode. The 220 Ohm resistor is “current-limiting” here, excess voltage drops on it, which protects the diode from crystal degradation and complete failure of LED1

Application

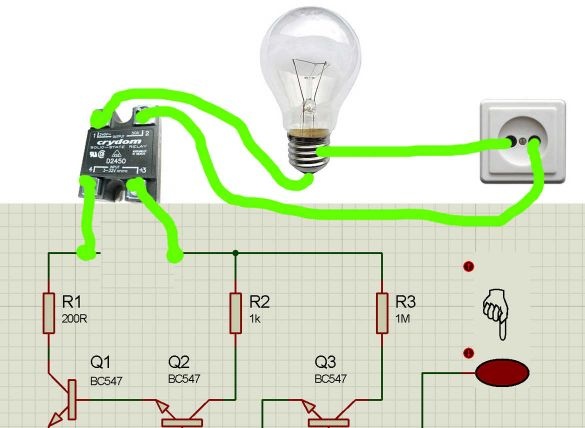

Well, the LED is on at the touch of a finger - so what? But the fact that instead of this LED we put a relay and now we can control almost any load, depending on the characteristics of the relay used. We put a powerful incandescent lamp connected to the network, and in the break of this circuit relay contacts. Now when you press, or rather touch the sensor, the lamp shines.

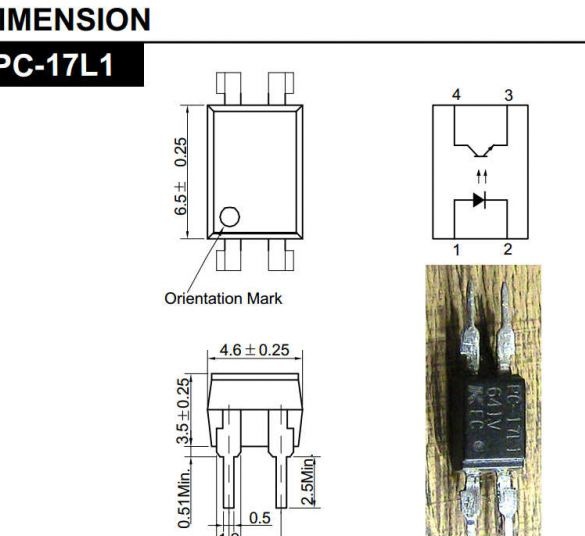

It is also possible to organize switching on / off the load using an optocoupler, if there is no relay, then there will also be galvanic isolation. This beautiful thing consists of an LED and a phototransistor, when the first one is on, it opens the transistor and current can flow through its FE.We include the necessary optocoupler leads in the sensor circuit instead of LED1, and the other two in the gap of the power source and any load. This item can be removed from the phone charges. Take, for example, the PC-17L1.

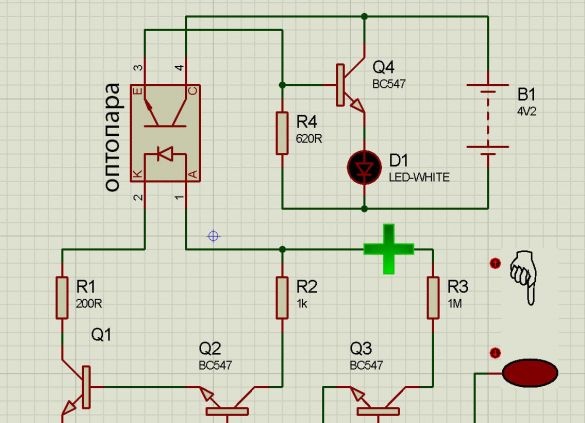

A little lower you see an addition to the main circuit, which shows how to connect an optocoupler to the sensor circuit, one transistor is also added, this is necessary so that you can connect a heavy load, and not just 20 mA LEDs.

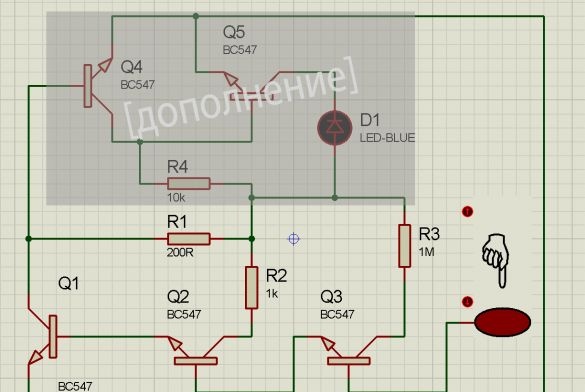

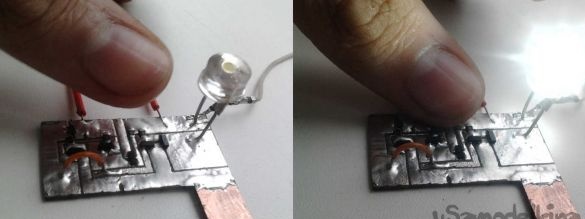

Instead of relays and optocouplers, it is possible to use two npn transistors. I did just that, you see the circuit. It works like this: Q5 should always be open, through a 10 kOhm resistor, but through the QE of an open Q4, a minus comes to the Q5 base and because of this it is closed. When you touch the sensor, then the minus goes through open Q1 to the Q4 base and closes it, now nothing prevents Q5 from staying open - the load works, and in my case a powerful 1 Watt LED shines brightly.

So it looks in assembled condition.

The sensor has no fixation, they touch - it is shining, they are released - it is not shining. If you want to make a fix, just add a trigger to the circuit, for example, on a KM555TM2 chip or any other (you can even implement this on a 555 timer). With the addition of a trigger system, when you touch the sensor, the load will be turned on until the next touch occurs or the power to the circuit disappears.

In practice, this can be used to quickly turn on and off the lighting in the room. Very comfortable, touched a small sensitive area, and the room is lit, a second touch will turn off the light. A small amount of energy will be lost, but this can be neglected.

Comments

The circuit works, but because of its simplicity, it is far from ideal. If the sensor is large, then the circuit may work even when you have not touched it, and if you brush your hair near the sensor with your hand, the LED may also light up. The way out of this situation is simple - a miniature touch sensor.

As already mentioned - the opening of Q3 occurs due to interference, you can see it on video, the LED does not light constantly, but winks at a high frequency, but this is clearly visible when shooting.

The brightness of the working diode is not large, if you only touch the base of the third transistor, but if you touch the plus power, then your body will act in the role of a resistor and transistor Q3 will go into saturation. But in this situation, for some, the meaning of the sensor is lost.

This scheme is very simple and is intended only to understand the principle of operation. electronic components used in serious constructions is not recommended.

Video