The main part of the wind generator is a screw, which converts wind energy into mechanical work. So the better the screw, the more and more stable the wind generator will be able to generate electricity.

Creating a screw, the author wanted to make it both fast and with a good starting moment, for this he even used a specialized program for calculating the efficiency coefficient.

Materials used to create the screw:

1) corrugated board thickness 0.6 mm

2) grinder

3) hammer

4) pliers

5) metal scissors

Consider in more detail the main points of work on the creation of the screw.

To begin with, he proceeded to basic calculations. First, pipes with a diameter of 110 and 160 mm were tested, since they were available from the author, but with good high-speed qualities they could not achieve a sufficient starting moment. Then he decided to check which diameter would be most acceptable from the side of the program. Calculations showed that the best coefficient are PVC pipes with a diameter of 250 and 315 mm. They have excellent indicators of both speed and starting moment.

But since there were no pipes of this diameter and it was rather difficult to find them, he decided to make the blades out of tin, which remained from the house sheathing with corrugated board. Previously, calculations were made with the screw from the 315th pipe in the program. The screw consisted of three blades and was obtained with a diameter of about 1.5 meters. According to calculations, the speed of such a screw was obtained with a high KIEV of 5-7, and the starting moment with a wind of 5 m / s was 0.25 Nm.

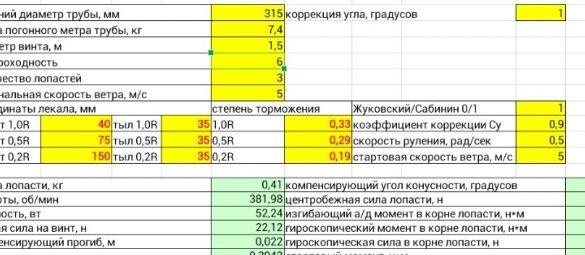

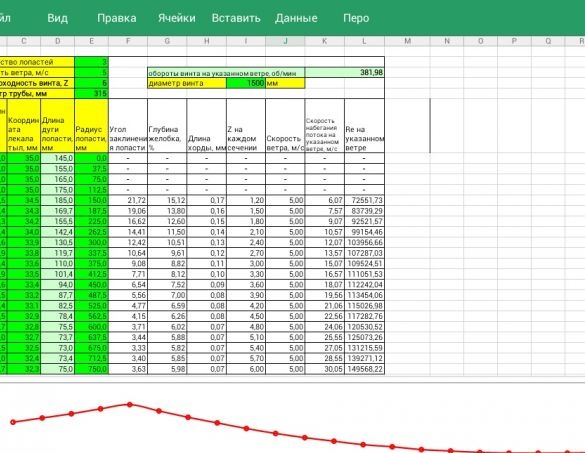

The following are excerpts from the blade efficiency program:

Below are all the basic calculations and data on sizes in millimeters, on the basis of which he began to manufacture the blades of the future screw.

From the scraps of the flooring, the most suitable pieces were selected in the amount of three pieces and processed with a grinder up to 75 cm. Using a hammer, the profile was given the appearance of a smooth sheet, and the back edge was immediately bent with a grip of 10 mm.

Further, on the sheets received, the author made a marking of the front line of the work, along which later the blades were cut. One centimeter was added to the main dimensions, since the author decided to bend the edges in order to give rigidity to the structure. The photos below show the line along which the metal will hem. The thickness of the sheet was about 0.6 mm, which made it possible to handle scissors for metal, not a grinder, so the blades turned out to be more even.

For rigidity, the edges of the blades were bent. This was done with pliers, followed by tapping with a hammer.

Thus, three blades were made, for each of which the author spent about twenty minutes of work.

Type of blades on the back side:

As you can see the blades are still flat, so the author proceeded to create a bend.

With the help of longitudinal tapping with the hammer blades, the shape of the gutters was shaped into a shape similar to the 315th pipe. For visual understanding, he drew a circle with a diameter of 320 mm and was guided by it during manipulations with the shape of the blades. Holes with a diameter of 6 mm were also drilled for the subsequent assembly of the screw.

Further, a hub was cut out of plywood and the author proceeded to the full-scale assembly of the screw. Practice has shown that blades of this design can easily withstand wind up to 15 m / s.

But the screw is already installed on the wind generator.

After installing this screw, he immediately showed himself to be the best. With a wind speed of 3-5 m / s, he was gaining speed and responding instantly to a change in wind. Prior to this, the screws installed on the generator either stopped periodically or did not have enough revolutions to produce a stable current.

Now charging has become almost constant, the current strength is from 0.5-1 A and is constantly increasing to 2 A. Due to the speed, charging does not stop, even in light winds. Thus, the author found an excellent way to build a reliable and stable propeller for a windmill from improvised means, which he sought. This manual can help you if you also have difficulty finding large PVC pipes in your area.